Automated Guided Vehicles (AGVs): Benefits, Types, and Best Practices

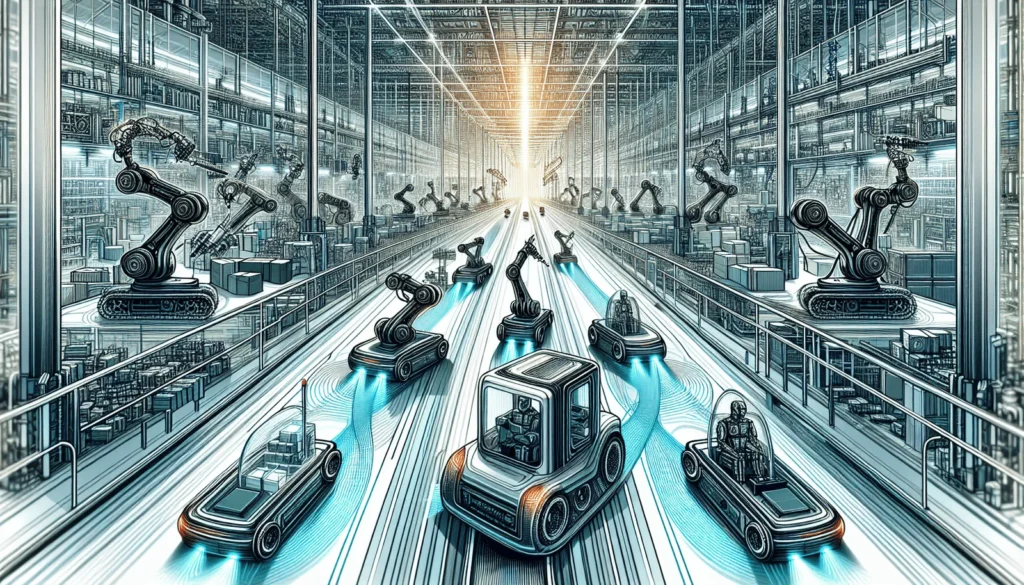

Automated Guided Vehicles (AGVs) are transforming warehouse operations by automating repetitive transport tasks. Instead of relying on forklifts and manual labor, AGVs safely and efficiently move pallets, carts, and materials across facilities. As warehouses seek to reduce costs and enhance productivity, AGVs are emerging as a cornerstone of modern material handling.

What are Automated Guided Vehicles?

Automated Guided Vehicles are mobile robots that follow predefined paths or use advanced navigation technologies to move goods. Unlike forklifts, AGVs operate autonomously, reducing the need for human drivers while ensuring consistent and predictable performance.

Benefits of AGVs

1. Lower Labor Costs

AGVs replace repetitive, low-value transport tasks, allowing workers to focus on higher-value activities.

2. Improved Safety

With sensors, cameras, and collision-avoidance systems, AGVs reduce workplace accidents compared to forklifts.

3. Consistent Productivity

AGVs operate 24/7 with minimal downtime, ensuring production and distribution lines remain uninterrupted and run smoothly.

4. Scalability

Facilities can add more vehicles as demand increases, without large infrastructure changes.

5. Data & Tracking

AGVs provide valuable data on material flows, travel times, and bottlenecks.

Types of Automated Guided Vehicles

Tugger AGVs – pull carts or trains of materials.

Unit Load AGVs – transport pallets, bins, or containers.

Forklift AGVs – automated versions of forklifts for pallet movement.

Automated Carts – smaller vehicles for light loads and kitting.

Hybrid AMR/AGVs – advanced vehicles that combine guided paths with autonomous navigation.

How AGVs Navigate

AGVs use different navigation technologies:

Wired Guidance – embedded wires in the floor.

Magnetic Tape – low-cost and flexible route changes.

Laser Guidance – reflectors placed around the facility.

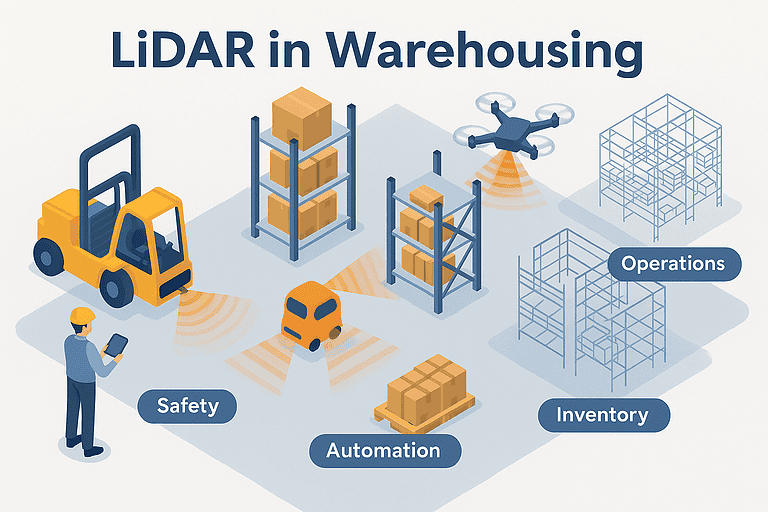

Vision & LiDAR – advanced navigation with dynamic adaptability.

Best Practices for Implementing AGVs

Start with a Pilot Project – deploy AGVs in a single area before scaling.

Evaluate ROI – consider labor savings, safety improvements, and throughput gains.

Integrate with WMS/WES – AGVs operate most effectively when connected to warehouse management systems (WMS) or warehouse execution systems (WES).

Plan for Maintenance – schedule preventive maintenance to avoid downtime.

Train Staff – Ensure employees know how to work safely alongside AGVs.

The Future of AGVs

As AI and machine learning continue to advance, AGVs will become increasingly flexible and adaptive. Expect tighter integration with Warehouse Execution Systems (WES), predictive maintenance, and even collaboration with autonomous mobile robots (AMRs). The line between AGVs and AMRs is blurring, paving the way for more intelligent, adaptable material handling systems.

Conclusion

Automated Guided Vehicles are no longer a futuristic concept—they are a proven, accessible solution that enhances safety, reduces labor costs, and increases warehouse efficiency. For companies looking to modernize operations, AGVs represent a smart investment in long-term competitiveness.

FAQ Section

What are Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are mobile robots that transport materials within warehouses, factories, and distribution centers. They move along predefined routes using navigation systems such as magnetic tape, lasers, or LiDAR.

What is the difference between AGVs and AMRs?

AGVs follow fixed paths or tracks, requiring pre-set infrastructure for navigation. Autonomous Mobile Robots (AMRs), on the other hand, use AI and sensors to navigate dynamically, making them more flexible in changing environments.

👉 Related blog: Autonomous Mobile Robots

What are the benefits of AGVs in warehouses?

AGVs improve safety, reduce labor costs, and provide 24/7 productivity. They also deliver consistent transport speeds, reduce product damage, and provide data insights on material movement.

👉 Related blog: Warehouse Safety

What types of AGVs are available?

Common types include tugger AGVs, unit load AGVs, forklift AGVs, automated carts, and hybrid AMR/AGVs. Each type is designed for specific load capacities and workflows.

👉 Related blog: Forklift in Warehouse

How much do Automated Guided Vehicles cost?

AGV costs vary depending on the type and capability. Basic models typically start at around $50,000 per vehicle, while advanced AGVs equipped with laser navigation or heavy-duty lifting capabilities can exceed $200,000. ROI is often achieved within 2–4 years through labor savings and safety improvements.

What industries use AGVs?

AGVs are utilized in various industries, including warehouses, automotive manufacturing, e-commerce fulfillment, food and beverage distribution, and pharmaceuticals. Any industry with repetitive material handling can benefit.

What is the future of AGVs?

Future AGVs will use AI, IoT, and predictive analytics to become more adaptive and intelligent. They will work alongside AMRs and robotics, integrating tightly with Warehouse Execution Systems (WES).

👉 Related blog: AI in Warehousing

External Link Recommendations for “Automated Guided Vehicles”

Introduction / Definition

🔗 MHI: What are Automated Guided Vehicles? – A respected supply chain association with a solid overview of AGVs.

Benefits of AGVs

🔗 McKinsey: Automation in logistics – Analysis of labor savings and productivity from automation.

Types of AGVs

🔗 Daifuku AGV Systems – Leading vendor outlining different AGV types and use cases.

Navigation Technologies

🔗 Toyota Material Handling AGVs – Real-world examples of magnetic tape, laser, and LiDAR navigation.