Warehouse Staff Training: 10 Best Online Training Programs

In the world of warehouse operations, the difference between a good team and a great one is training. But with busy schedules and busy budgets how can you get your staff trained? Let’s get into the 10 top online courses for warehouse staff training.

Types of Training for Warehouse Staff

A broad skill set is key to success in operations. Here are the areas where training can make a big impact:

Safety Training

Safety is the number one priority in any warehouse environment. Training can prevent accidents, reduce injuries, and create a culture of awareness.

Key topics:

Hazard and risk assessment

Lifting techniques and ergonomics

Emergency procedures

PPE usage

Importance of safety in operations

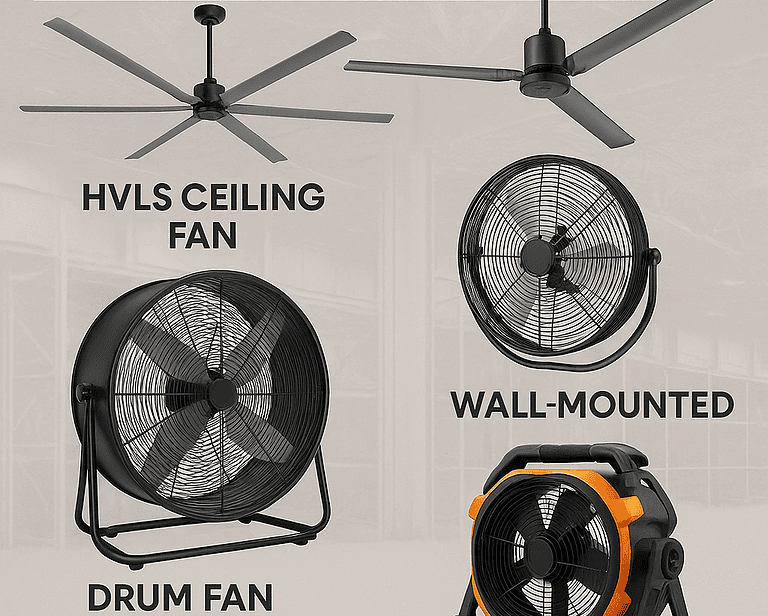

Warehouse Worker Equipment Operation

Modern warehouses utilize various types of equipment; forklift drivers play a crucial role in efficiently moving and managing inventory.

Essential equipment training covers:

Forklift operation and maintenance

Pallet jack usage

Conveyor system management

Automated guided vehicles (AGVs)

Warehouse Worker Inventory Control

Inventory control is key to warehouse success. Training warehouse workers in this area can improve accuracy and reduce costs.

Key areas:

Inventory tracking systems

Cycle counting

Stock rotation

Demand forecasting

Inventory control is also crucial for fulfilling warehouse orders, as it ensures that Order Pickers and Package Handlers can select, pack, and label products accurately using warehouse management systems and automation.

Warehouse Operations and Management Systems (WMS)

As technology becomes increasingly integrated into warehouse operations, WMS skills will become more crucial than ever.

Key areas:

Data entry and retrieval

Report generation and analysis

Order processing workflows

System troubleshooting

Lean Warehousing and Continuous Improvement

Lean principles can improve warehouse efficiency and reduce waste.

Training should cover:

5S (Sort, Set in order, Shine, Standardize, Sustain)

Value stream mapping

Kaizen events and continuous improvement processes

KPIs for warehousing

The warehouse manager is key to implementing lean principles and continuous improvement processes to ensure efficiency, safety and productivity.

Compliance and Regulations

Compliance with industry regulations is crucial for avoiding fines and maintaining a strong reputation.

Essential compliance training for warehouse workers:

OSHA warehouse safety standards

HAZMAT

Food safety (if applicable)

Environmental compliance

Train your staff in these six areas, and you’ll have a solid foundation for a safe, efficient, and productive warehouse.

Online Courses and Certifications

OSHA Warehouse Safety Certification

- Provider: OSHAcademy

- Course: Warehouse Safety (Course 845)

Key Features:

OSHA standards for warehouses covered

Self-paced online learning

Certificate of completion

Compliance with federal regulations and promotes a safety culture.

Forklift Operator Certification for Warehouse Workers

Provider: National Safety Council

Course: Forklift Operator Training

Key Features:

OSHA compliant training

Online interactive modules

Hands-on evaluation

Certification is mandatory for forklift drivers and key to efficiency and safety in operations. It prevents accidents and supports the specific skills required for this role.

Inventory Management and Control Certificate

- Provider: American Production and Inventory Control Society (APICS)

Course: Principles in Inventory Controls

Key Features:

Industry recognized certification

In-depth inventory control techniques

Exam prep materials included

Improves inventory accuracy and reduces stock holding.

Warehouse Management Systems (WMS) Training

Provider: LinkedIn Learning

Course: Learning Warehouse Management Systems

Key Features:

WMS software overview

Practical scenarios

Mobile access

Improves daily operations and data management.

Lean Six Sigma for Warehousing

Provider: edX

Course: Lean Six Sigma for Supply Chain Management

Key Features:

Industry experts

Project-based learning

Verified certificate option

It gives staff the tools to improve and reduce waste.

HAZMAT

Provider: Hazmat School

Course: DOT Hazmat General Awareness Training

Key Features:

DOT compliant training

Regularly updated to reflect current regulations

24/7 online access

Safe handling of dangerous goods and regulatory compliance.

Each course provides valuable skills and knowledge to improve operations. When choosing courses for your team, consider your industry, current skill gaps, and long-term operational goals.

Material handlers are key to the safe handling of hazardous materials, compliance with safety standards, and warehouse efficiency.

Platforms for Warehouse Training

Coursera

Coursera partners with top universities and companies to offer various courses.

- Notable Courses:

- Supply Chain Operations by Rutgers University

- Six Sigma Yellow Belt Specialization by the University of Georgia

- Pros:

- High-quality content from reputable institutions

- Flexible learning schedules

- Option for verified certificates

- Cons:

- Some courses may be more academic than practical

- Higher-tier certifications can be expensive

edX

Founded by Harvard and MIT, edX offers courses from leading global institutions.

- Notable Courses:

- Supply Chain Analytics by MIT

- Lean Production by TUMx

- Pros:

- University-level courses

- Self-paced learning

- Many free courses are available (certificates cost extra)

- Cons:

- Less focus on hands-on, industry-specific training

LinkedIn Learning

Formerly, Lynda.com offers a vast library of professional development courses.

- Notable Courses:

- Cert Prep: Lean Six Sigma Green Belt

- Learning Warehouse Management Systems

- Pros:

- Wide variety of bite-sized, practical courses

- Included with LinkedIn Premium subscriptions

- Certificates can be added directly to LinkedIn profiles

- Cons:

- Less rigorous than academic or industry-specific certifications

APICS (Association for Supply Chain Management)

Leading professional association for supply chain management.

- Notable Certifications:

- Certified in Production and Inventory Management (CPIM)

- Certified Supply Chain Professional (CSCP)

- Pros:

- Industry-recognized certifications

- Comprehensive, in-depth material

- Networking opportunities within the industry

- Cons:

- More expensive than many online options

- Rigorous exams require significant preparation

Material Handling Institute (MHI)

The US’s largest material handling, logistics, and supply chain association.

- Notable Offerings:

- Fundamentals of Warehousing course

- Various webinars and online learning resources

- Pros:

- Industry-specific content

- A mix of free and paid resources

- Access to the latest industry trends and best practices

- Cons:

- More limited course selection compared to larger platforms

When choosing a platform, consider factors such as your budget, the specific skills your team needs to develop, and the level of certification or recognition required in your industry.

Many of these platforms offer free trials or sample courses, which can be a great way to assess the quality and relevance of their offerings before committing.

Choosing the Right Training

Selecting the most appropriate training program for your warehouse staff is crucial for maximizing the return on your investment. Here are key factors to consider:

Assessing Your Team’s Needs

- Conduct a skills gap analysis

- Survey your employees about their perceived weaknesses

- Review performance metrics to identify areas for improvement

- Consider upcoming changes in technology or processes

- Align training with business goals

- Identify which skills will have the most impact on your operations

- Consider both short-term needs and long-term strategic objectives

Considering Industry-Specific Requirements

- Regulatory compliance

- Ensure courses meet OSHA and other relevant standards

- Look for industry-recognized certifications

- Specialized equipment or processes

- Choose programs that cover the specific tools and systems you use

- Consider customized training options for unique needs

Evaluating Course Content and Delivery Methods

- Content quality

- Look for courses developed by subject matter experts

- Check for recent updates to ensure relevance

- Learning formats

- Consider a mix of video lectures, interactive exercises, and quizzes

- Look for programs that offer hands-on components or simulations

- Accessibility

- Ensure compatibility with your team’s devices and work schedules

- Consider options for offline access or mobile learning

Checking for Accreditation and Recognition

- Industry associations

- Look for endorsements from organizations like APICS or MHI

- Educational accreditation

- For more academic programs, check for recognition by educational bodies

- Employer recognition

- Research which certifications are valued by top employers in your field

Considering Cost and ROI

- Budget constraints

- Compare pricing models (per-course, subscription, or bulk pricing)

- Factor in any additional costs (exam fees, materials, etc.)

- Return on investment

- Estimate the potential impact on productivity and efficiency

- Consider the long-term value of the skills acquired

Reviewing User Feedback and Success Stories

- Course reviews

- Look for detailed feedback from past participants

- Pay attention to comments about practical applicability

- Case studies

- Seek out success stories from companies similar to yours

- Look for concrete examples of how the training improved operations

By carefully considering these factors, you can select a training program that fills your team’s skill gaps and aligns with your company’s goals and culture. Remember, the most effective training programs are relevant, engaging, and directly applicable to daily operations.

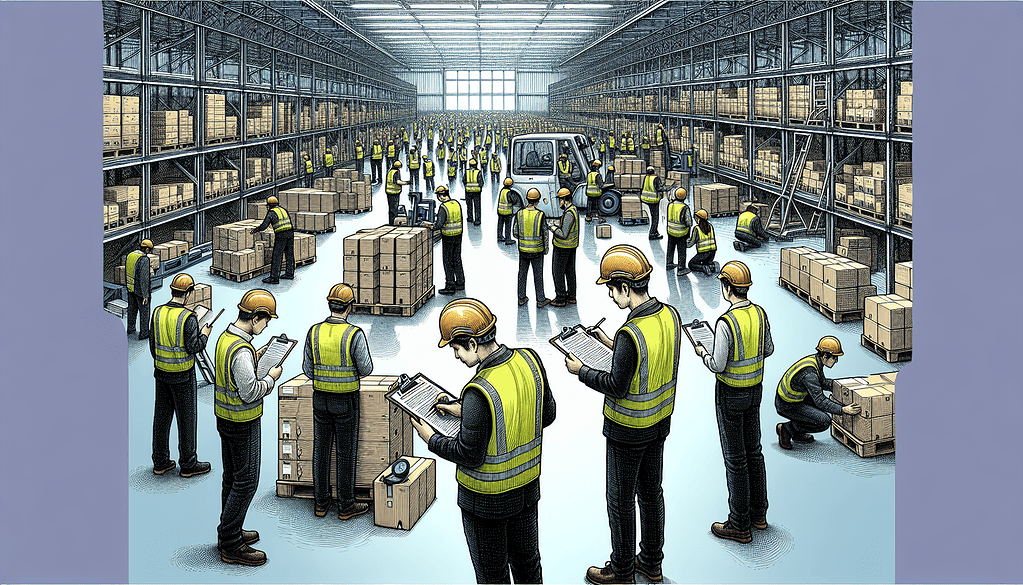

Implementing a Training Program

A successful implementation is key to maximizing the benefits of your chosen training program. Here’s how to effectively roll out your warehouse staff training:

Creating a Training Schedule

- Set realistic timelines

- Consider workload and peak seasons when scheduling training

- Allow enough time for employees to absorb and apply new knowledge

- Develop a phased approach

- Start with foundational courses before moving to advanced topics

- Prioritize critical skills and compliance-related training

- Balance group and individual learning

- Schedule some group sessions for team-building and shared learning

- Allow flexibility for self-paced individual learning

Motivating Staff to Participate

- Communicate the benefits

- Explain how the training will make their jobs easier or safer

- Highlight opportunities for career advancement

- Provide incentives

- Offer recognition for completed courses

- Consider tying training completion to performance reviews or bonuses

- Lead by example

- Have management participate in relevant training

- Share success stories from those who have completed the programs

Tracking Progress and Measuring Results

- Use learning management systems (LMS)

- Monitor course completion rates

- Track individual progress and identify those who may need additional support

- Conduct regular assessments

- Use quizzes or practical tests to ensure knowledge retention

- Encourage employees to apply new skills in their daily work

- Gather feedback

- Ask employees about the relevance and quality of the training

- Use this feedback to refine your training program over time

Reinforcing Learning in the Workplace

- Provide opportunities for practical application

- Assign projects that allow employees to use their new skills

- Create mentoring programs to support skill development

- Update standard operating procedures

- Incorporate new best practices learned from training into daily operations

- Ensure all documentation reflects the most current processes

- Foster a culture of continuous learning

- Encourage knowledge sharing among team members

- Celebrate improvements and innovations that result from training

Addressing Challenges

- Technical issues

- Ensure IT support is available for online learning platforms

- Provide alternatives (e.g., printed materials) if digital access is limited

- Time constraints

- Consider allocating specific work hours for training

- Break longer courses into manageable segments

- Resistance to change

- Address concerns openly and emphasize the long-term benefits

- Involve skeptical employees in the training selection process to increase buy-in

By following these implementation strategies, you can create a supportive learning environment that encourages participation and ensures the skills learned are effectively applied in your warehouse operations.

Return on Investment (ROI) of Warehouse Training

Investing in training for your warehouse staff can yield significant benefits. Here’s how to measure and maximize the ROI of your training programs:

Improved Productivity

- Increased efficiency

- Track metrics like picks per hour or inventory turnover rate

- Compare performance before and after training implementation

- Reduced errors

- Monitor error rates in order fulfillment and inventory counts

- Calculate cost savings from fewer mistakes

- Faster onboarding

- Measure time-to-proficiency for new hires

- Compare training costs to recruitment and turnover expenses

Reduced Accidents and Errors

- Safety improvements

- Track the number of workplace incidents and near-misses

- Calculate savings from reduced workers’ compensation claims

- Equipment maintenance

- Monitor the frequency of equipment breakdowns

- Assess cost savings from proper equipment usage and maintenance

- Compliance adherence

- Track any fines or penalties avoided due to improved compliance

- Consider the reputational value of maintaining a stellar safety record

Enhanced Employee Satisfaction and Retention

- Job satisfaction surveys

- Conduct regular surveys to gauge employee engagement

- Look for correlations between training completion and job satisfaction

- Employee retention rates

- Compare turnover rates before and after implementing training programs

- Calculate the cost savings from reduced recruitment and onboarding needs

- Career Advancement

- Track internal promotions and career progression

- Assess the value of developing talent internally versus external hiring

Better Compliance and Reduced Liability

- Audit results

- Compare the outcomes of internal and external audits pre- and post-training

- Quantify the financial impact of improved audit performances

- Insurance premiums

- Monitor changes in insurance costs as safety records improve

- Calculate long-term savings from reduced premiums

- Legal costs

- Assess any reduction in legal issues or disputes

- Consider the value of avoiding potential lawsuits through proper training

Calculating ROI

- Direct ROI calculation ROI = (Gains from training – Cost of training) / Cost of training * 100

- Factors to consider in your calculation:

- Direct costs: Course fees, materials, time off for training

- Indirect benefits: Improved morale, enhanced company reputation

- Long-term impact: Sustained performance improvements over time

- Intangible benefits

- Consider qualitative improvements like better teamwork or innovation

- Assess the impact on customer satisfaction and loyalty

Maximizing ROI

- Align training with strategic goals

- Ensure each program directly supports key business objectives

- Reinforce learning

- Implement systems to apply new skills immediately in the workplace

- Continuous evaluation

- Regularly assess the effectiveness of each training program

- Be willing to adjust or replace programs that aren’t delivering value

By carefully measuring and analyzing the ROI of your warehouse training programs, you can justify the investment to stakeholders and continuously refine your approach to maximize benefits.

Remember, while some returns are immediately quantifiable, others may take time to fully materialize. A comprehensive, long-term view of ROI will provide the most accurate picture of your training program’s value.

Conclusion

As explored throughout this post, investing in essential training programs for warehouse staff is not just a regulatory requirement or a nice-to-have – it’s a strategic imperative for any business looking to stay competitive in today’s fast-paced logistics landscape.

Recap of the Importance of Ongoing Training

The warehouse industry is evolving rapidly, with new technologies, changing consumer demands, and increasing regulatory pressures. Ongoing training ensures that your team stays ahead of these changes, maintaining efficiency, safety, and compliance.

Each training area contributes to a more robust and productive warehouse operation, from fundamental safety practices to advanced inventory management techniques.

The Compounding Benefits of a Well-Trained Team

Remember, the benefits of training compound over time. A well-trained team is:

- More efficient and productive

- Safer and more compliant with regulations

- More satisfied and likely to stay with your company

- Better equipped to handle challenges and innovate

These factors combine to create a workplace that’s not only more profitable but also more resilient and adaptable to future industry changes.

Encouragement to Invest in Staff Development

While the initial investment in training may seem significant, the tangible and intangible ROI makes it a wise business decision.

By carefully selecting the right programs, implementing them effectively, and consistently measuring their impact, you can create a culture of continuous improvement that benefits everyone – from individual employees to the company as a whole.

Call to Action

- Assess your current training needs: Start by evaluating your team’s skills and identifying improvement areas.

- Explore the recommended courses: Review the online courses and certifications we’ve discussed and consider which might be most beneficial for your team.

- Develop a training plan: Create a structured approach to implementing new training programs, considering both immediate needs and long-term goals.

- Start small and scale up: Begin with a pilot program to test the waters, then expand based on results and feedback.

- Commit to ongoing evaluation: Regularly assess the impact of your training initiatives and be prepared to adapt as needed.

Remember, your team is your most valuable asset in warehouse management. By investing in their skills and knowledge, you’re not just improving your operations but building a foundation for long-term success and growth.

Are you ready to take your warehouse operations to the next level through strategic staff training? The future of your business may depend on it.