Best Picker in Warehouse: 10 Essential Secrets to Success

Are you considering a position as a picker in warehouse environments or seeking to optimize your current role? Understanding the duties, skills required, and the conditions you’ll work under is paramount.

This article dives into a warehouse picker’s core responsibilities, outlines the job’s physical and skill-based requirements, and provides actionable insights for those aiming to enter or advance in this field.

Expect to learn about operational safety, necessary qualifications, and job-seeking tips—all crucial elements for a successful career as a selector in warehouse settings.

Key Takeaways

- Warehouse pickers are crucial in selecting, packing, and organizing goods. To ensure customer satisfaction, they must balance accuracy with the physical demands of managing high-volume orders.

- Key skills for a successful picker include attention to detail, time management, and the ability to collaborate and communicate effectively. Technology plays an essential role in enhancing accuracy and efficiency.

- Safety is imperative when operating warehouse equipment like forklifts, pallet jacks, and hand trucks. Certifications and training are beneficial for career advancement, and job seekers should employ strategic job search tactics, tailor their application materials, and prepare thoroughly for interviews.

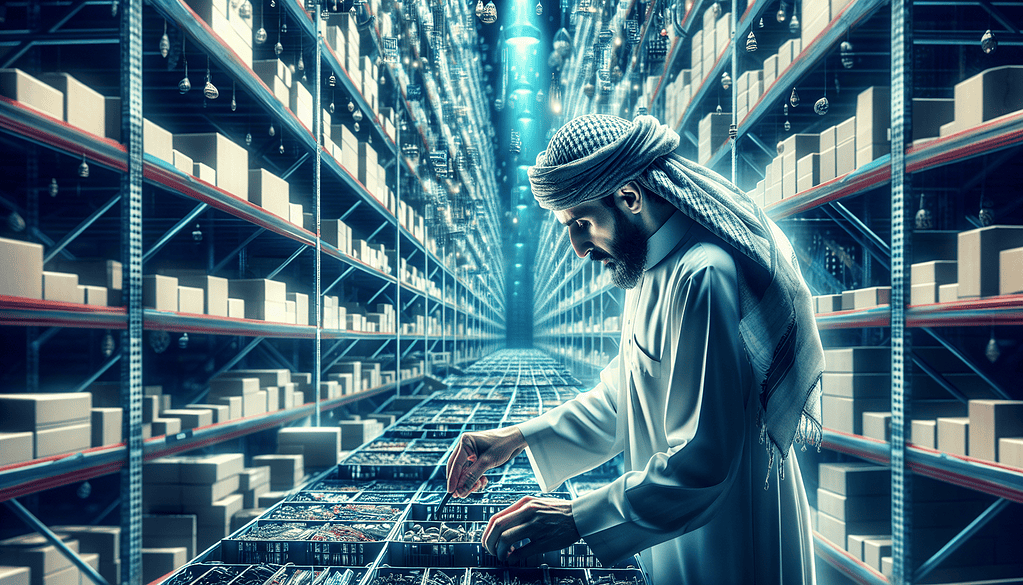

The Prominent Role of a Warehouse Picker

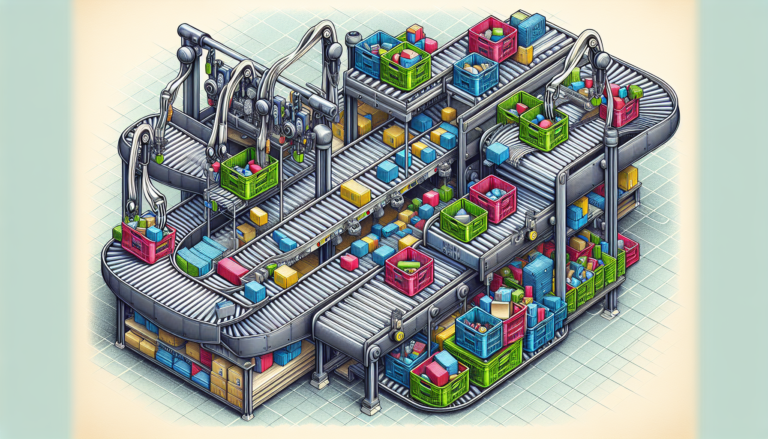

Order pickers are vital components to the supply chain. They are tasked with accurately selecting products based on incoming orders, replenishing inventory, and managing the classification and arrangement of merchandise within a warehouse setting.

These workers often work with sales personnel, warehouse employees, and other order pickers. They may also engage with clients and assorted experts as part of their duties.

Understanding the order picker job description is essential as it outlines the responsibilities, qualifications, and skills required for the role.

These include tasks such as picking products from shelves, organizing and storing items, maintaining communication within the team, and being a crucial part of the supply chain.

The Picker’s Primary Responsibilities

Order pickers bear the responsibility for the following:

Accurately select and prepare products to fulfill customer orders.

Correctly retrieving items from their specific warehouse locations involves organizing and placing products on shelves, racks, or other designated storage areas.

We verify that each product matches the required quantity, quality, and dimensions before placing them into shipping containers.

Achieving precision in filling customer orders is imperative to prevent errors leading to customer dissatisfaction and potential extra costs incurred by the warehouse. Pickers must ensure accuracy when building pallets and handling a substantial volume of daily orders.

This involves meeting predetermined picking quotas essential for sustaining workflow efficiency within the facility. Order pickers’ meticulous work is vital for maintaining an effective operation that serves customer needs.

Working Conditions and Physical Demands

Order pickers Operate under the following work conditions:

They are scheduled for a 40-hour week, usually from Monday to Friday.

Their responsibilities are carried out inside warehouses and distribution centers where they spend significant stretches on their feet.

Due to the heavy lifting involved with the job, these workers need substantial physical strength and endurance. They must handle hefty items safely and regularly throughout their shifts.

To reduce strain and prevent injury, pickers must keep pallet loads at an optimal height known as the ‘power zone’—above knee level but below shoulder height—and close to one’s body.

Mastering correct lifting techniques is crucial for managing these physically taxing tasks effectively.

Essential Skills for Successful Warehouse Pickers

The job description for a picker highlights the necessity of possessing not only physical capabilities but also an array of skills and attributes essential to perform effectively, such as:

Sufficient physical strength

Stamina

Adeptness in performing manual tasks

The skill to adhere meticulously to guidelines ensuring accuracy during the picking process

Yet, excelling at the picker role transcends mere muscular strength.

Attention to Detail and Accuracy

Attention to detail is one such skill that is crucial for warehouse pickers to prevent order errors, ensure customer satisfaction, and avoid costly mistakes.

Order pickers must retrieve orders precisely, confirming that the correct size and quantity of products are selected, which upholds high-quality, high-quality order fulfillment.

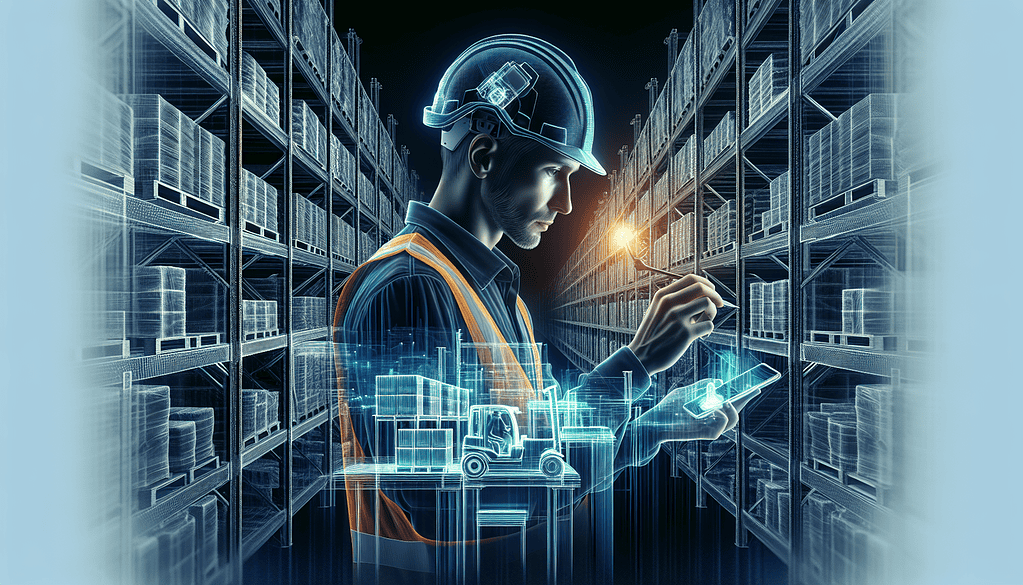

The role of technology in achieving this accuracy cannot be overlooked. Utilizing technology such as voice picking systems or RF devices aids pickers in locating and retrieving products with greater precision. Thus, it is an important aspect of ensuring accuracy in their role.

Technology retrieves orders more efficiently than ever, making it a crucial component in modern warehouses.

Time Management and Efficiency

Managing time effectively is a critical ability for proficient warehouse pickers. Meeting the job’s requirements efficiently plays a vital role. This efficiency isn’t just about how fast items are picked but also ensures that orders are fulfilled accurately.

Under the pressure of expected productivity levels, warehouse pickers must demonstrate their capacity to select items promptly. The skill of swiftly and competently executing tasks under such pressure greatly contributes to a selector’s achievement within the warehouse setting.

Communication and Collaboration

Effective communication and the ability to collaborate are vital skills for warehouse pickers. These capabilities enable them to work together seamlessly, which is fundamental in processing orders swiftly and adhering strictly to safety protocols within the warehouse.

Warehouse pickers must possess robust collaborative and communicative abilities, allowing clear interaction with fellow staff members. This ensures the smooth operation of the entire warehouse environment, where all members function cohesively towards shared objectives, much like a finely tuned machine.

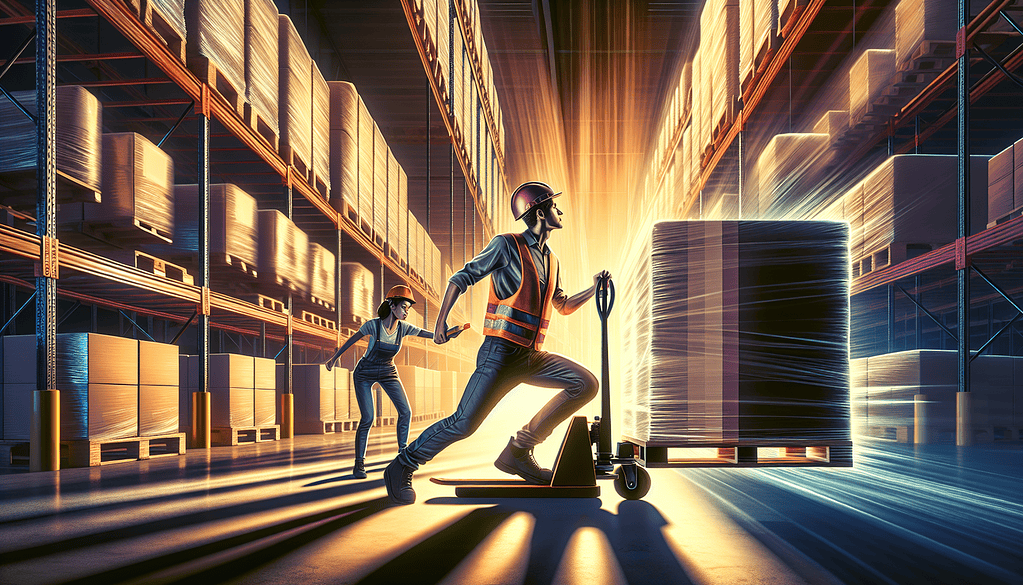

Operating Warehouse Equipment Safely and Efficiently

Order pickers in the warehouse play a pivotal role by adeptly operating equipment such as forklifts and pallet jacks, ensuring orders are compiled and sent out with precision and timeliness.

They must adhere to stringent safety protocols, including conducting proper inspections of the warehouse equipment, to safeguard workers’ well-being while complying with company policies.

Maintaining equipment post-completion of orders helps maintain an uninterrupted and efficient workflow within the warehouse environment.

Pallet Jacks and Hand Trucks

Pallet jacks and hand trucks are frequently used in warehouse settings. To guarantee the safe transit of goods, heavier items must be initially loaded on these devices to maintain balance and prevent them from toppling.

Before deploying pallet jacks and hand trucks within the warehouse environment, they should undergo thorough examinations for any signs of wear or damage, with special attention given to ensuring tire pressure adequacy and wheel performance.

Maintaining these vehicles in prime condition is crucial for reducing accident risks in warehouses while preserving a streamlined flow of operations.

Forklifts and Other Heavy Machinery

Safety and training are paramount in operating forklifts and similar heavy machinery. Compliance with OSHA guidelines, which mandate certifications, is essential for operating this type of equipment.

Operators handling warehouse forklifts must possess the certification that aligns with OSHA Standard 1910.178 related to powered industrial trucks. Those seeking picker roles should have prior experience using forklifts and may be expected to hold a license that legally permits them to operate such machinery.

Education and Experience for Picker Positions

Typically, the minimal educational requirement for order picker roles is at least a high school diploma or GED. New pickers usually undergo on-the-job training for less than one month to acquire the essential skills needed to commence work.

Entry-Level Opportunities and Advancement

Embarking on a career as an energetic order picker involves starting in a foundational role. This position holds the potential for growth into more advanced roles such as technician, team leader, or office manager.

As they gain experience and potentially pursue Education, those who process orders may ascend to higher-level positions like order analyst, coordinator, or supervisor—roles that enable them to manage customer orders more efficiently.

Grasping the nuances of the picker job description is key for anyone aiming to advance in this career path.

Qualifications could be instrumental for pickers aiming at specialized advancement opportunities, such as becoming an order inspector, dispatcher, or lead packer.

Above all else, accumulating field experience is the most vital step towards progressing through their professional journey of handling customer requests diligently and proficiently.

Certifications and Training Programs

Training programs and certifications are crucial in improving warehouse pickers’ abilities and job prospects. Programs such as the Certified Professional in Supply Management (CPSM) can help these workers gain knowledge about effective warehouse operations.

The proper certifications for handling equipment like forklifts are essential for maintaining warehouse safety standards and operational efficiency. These educational advancements equip pickers with vital skills and foster professional growth and career development.

Tips for Job Seekers: Finding Picker Positions

For those pursuing a role as a warehouse picker, there are multiple efficient methods to uncover job vacancies and obtain the position. Engaging with existing warehouse staff might disclose available but not publicly listed opportunities for picker positions.

Job Search Strategies

Searching for job openings as a warehouse picker can be accomplished by exploring various storage location vacancies through company websites and online job boards catering to the logistics and warehouse sector.

Companies often employ tactics such as participating in job fairs or posting on widely recognized platforms such as Indeed to attract potential pickers, offering many opportunities for individuals seeking employment in the warehousing field.

Crafting a Strong Resume and Cover Letter

Composing a customized resume and accompanying cover letter is essential to the job application journey. Initiate your resume with a summary or objective that succinctly presents your qualifications, fine-tuned to highlight how they align with the demands of a picker role in a warehouse.

Incorporate specific instances from past employment and significant achievements that directly correlate with the duties and abilities needed for the warehouse picker position. By doing so, you will distinguish yourself as a candidate and make an impactful statement to prospective employers.

Acing the Interview Process

Acing the interview process hinges on thorough preparation. Rehearsing answers to typical interview questions for picker roles can greatly enhance one’s performance during an interview.

Before attending an interview, it is critical to familiarize oneself with the company and understand what the picker position entails.

Presenting oneself in suitable attire for the interview is vital in creating a favorable impression on prospective employers. Not only does dressing properly increase your self-assurance, but it also conveys your professional attitude and earnestness regarding the position.

Pro Tip: If you are an hourly worker wanting to move into a management role, here are the things we look for specifically.

- Do your peers view you as credible? If needed, would they follow you if you ‘headed up’ a small project team?

- Are you trustworthy, on time to work, have a safe working history, and support others when asked?

- Can you listen to others empathetically and communicate those concerns upward?

- Are you willing to learn? Will you work hard and learn how to work smart? Will you not complain when shit hits the fan?

When I am looking to hire someone, you must be highly respected and trusted by your peers, be a positive influence on your team (positive attitude), and follow all of the rules all of the time. Remember that for management to promote you, they must trust you can do their job when they are in a meeting or on vacation.

You won’t take the victim role and blame others; if you have any issues/concerns, you will speak to your mentor immediately and accept coaching, and you will support the initiatives of the business whether you agree with them or not.

The biggest mistake we can make is promoting someone into a leadership role before they are ready and then having to let them go (terminate). Good luck!

Summary – Picker in Warehouse

The position of a warehouse picker is challenging and fulfilling. It requires strong attention to detail, robust physical strength, and superior time management abilities.

Warehouse pickers are vital components within the supply chain framework. They efficiently operate warehouse equipment in a fast-paced setting. The right combination of expertise, training, and proficiency can pave the way for career growth in this role.

If you’re contemplating entering this field or are an adept picker aiming for progression, remember these points along your professional journey.

Frequently Asked Questions

What is the role of a warehouse picker?

A warehouse selector is responsible for pulling products for orders, restocking merchandise, maintaining orders within the warehouse setting, and working with fellow warehouse personnel and sales departments. This role is crucial for effective inventory management and precise order completion.

What skills are essential for a successful warehouse picker?

Key skills vital for a proficient warehouse picker include the ability to handle physical demands, meticulousness, effective communication prowess, teamwork capabilities, and strong time management. Such competencies are imperative for achieving peak efficiency within a warehouse environment.

Who gets to operate warehouse equipment (order picker)?

A warehouse picker commonly operates forklifts, pallet jacks, and hand trucks to assemble and dispatch orders accurately and on time. These tools are essential for their daily tasks.

What are the education and experience requirements? Do I need a high school diploma?

To be eligible for a position as an order picker, candidates must possess a minimum of a high school diploma or GED. Once hired, new pickers typically receive training on the job.

What are tips for job seekers looking for picker positions?

When searching for picker roles, it is essential to explore job openings through online job boards and the careers sections of company websites and leverage your professional network. While preparing for potential interviews, emphasize developing a robust resume and an effective cover letter.