The 3 Best Vertical Storage Systems for Warehousing

In the race for warehouse efficiency, sometimes the only direction to go is up. And while there are many vertical storage solutions on the market, we’ve seen our fair share sitting idle, covered in dust. Here are our recommendations and the reasons why.

Introduction

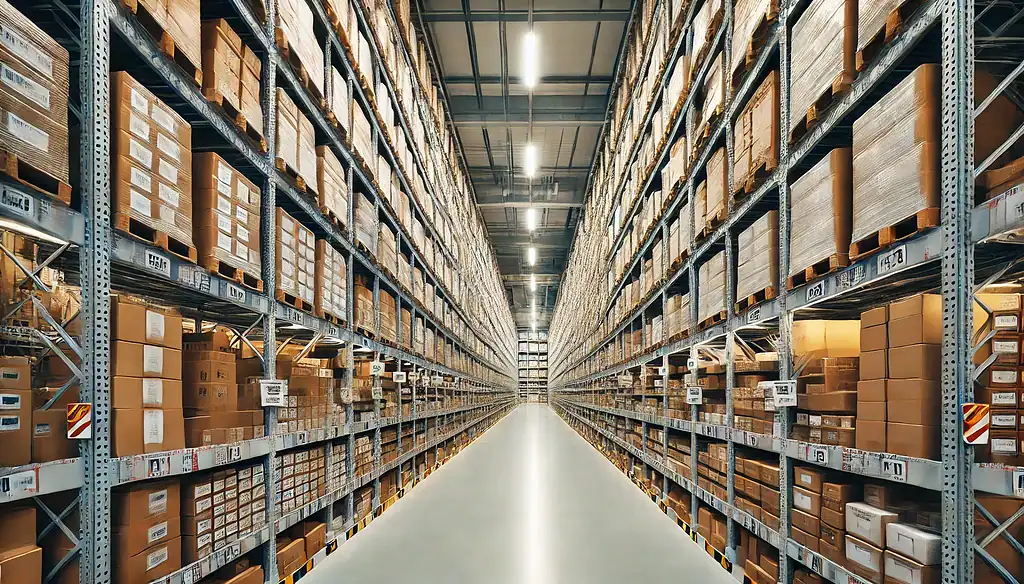

Imagine walking into a warehouse where forklifts zoom up and down towering shelves, robotic arms effortlessly retrieve items from heights that would make most people dizzy, and valuable floor space is utilized to its fullest potential. This isn’t a scene from a sci-fi movie; it’s the reality of modern warehouses equipped with cutting-edge vertical storage systems.

This blog post will explore the best vertical storage solutions available today. We’ll investigate how these systems transform warehouses from cluttered mazes into sleek, efficient productivity powerhouses.

Whether you’re a warehouse manager looking to optimize your space, a business owner aiming to reduce operational costs, or simply curious about the latest innovations in logistics, this guide will provide valuable insights into the vertical revolution sweeping the warehousing world.

1. Bradford Systems

Bradford Systems is a comprehensive space problem-solving company specializing in storage solutions for various organizations. They offer various services, including high-density storage equipment, shelving, and digitization services.

Pros

- Customized approach: Bradford Systems emphasizes understanding client needs before proposing solutions, which can lead to more tailored and effective outcomes.

- Expertise: With their claimed background and knowledge, they likely bring valuable experience to complex storage challenges.

- Holistic solutions: They aim to integrate physical and digital storage methods, potentially offering more comprehensive solutions than competitors focused solely on physical storage.

- Versatility: Their services span various industries and needs, from office lockers to preserving historic artifacts, indicating adaptability.

- End-to-end service: Bradford Systems offers support throughout the process, which can benefit clients seeking a hands-on partner.

Cons

- Potential higher costs: Their custom, high-touch approach may come at a premium compared to more standardized solutions.

- Longer implementation time: The emphasis on understanding client needs and customization might lead to longer project timelines.

- Dependency: Their full-service model could create over-reliance on Bradford for ongoing support and maintenance.

- Possible overengineering: There’s a risk that their solutions might be more complex than necessary for simpler storage needs.

- Limited scalability: While they offer custom solutions, it’s unclear how easily their systems can scale with rapidly growing organizations.

Case Study Video

Summary

Bradford Systems offers a comprehensive, customized approach to storage solutions. They may be particularly suitable for organizations with complex storage needs or those requiring high support throughout the implementation process. However, companies with simpler requirements or tighter budgets might find their services potentially excessive.

2. Vertical Storage USA

Vertical Storage USA specializes in vertical storage solutions, with a particular emphasis on Vertical Lift Modules. They position these systems as a cost-effective alternative to warehouse expansion.

Pros

- Space optimization: VLMs maximize vertical space usage, potentially eliminating the need for costly warehouse expansions.

- Improved organization: The computerized and indexed storage database enhances inventory management and retrieval efficiency.

- Labor efficiency: By centralizing inventory and automating retrieval, VLMs can significantly reduce employees’ time locating and fetching items.

- Enhanced safety: The automated system reduces the need for employees to operate heavy machinery or work at heights, potentially lowering workplace accidents.

- Improved security: VLMs offer better inventory control with authorized access and usage tracking, potentially reducing theft and inventory discrepancies.

- Flexibility in offerings: They provide new and used equipment, catering to different budget constraints.

Cons

- Initial investment: While potentially cost-effective in the long run, the initial outlay for a VLM system could be substantial.

- Dependency on technology: Reliance on computerized systems may lead to operational disruptions if technical issues occur.

- Training requirements: Employees will need training to use the new system effectively, which could temporarily impact productivity.

- Limited product range: The company seems to focus primarily on VLMs, which might not be suitable for all inventory or warehouse setups.

- Potential overselling: The description presents VLMs as a near-perfect solution, which might lead to unrealistic expectations.

- Unclear customization capabilities: While they mention tailoring solutions, it’s unclear how flexible their systems are for unique warehouse needs.

Summary

Vertical Storage USA’s Vertical Lift Modules appear to offer significant benefits in terms of space utilization, efficiency, and security for warehouse operations. They may be particularly suitable for businesses struggling with space constraints or looking to optimize their picking processes. However, the substantial initial investment and potential reliance on a single technological solution should be carefully considered.

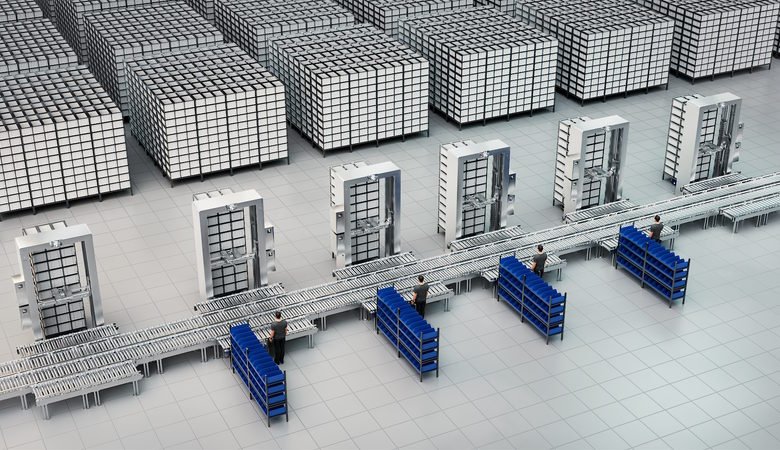

3. Conveyco

Conveyco is a systems integrator specializing in vertical warehouse storage solutions, offering both manual and automated options to optimize warehouse operations.

Pros

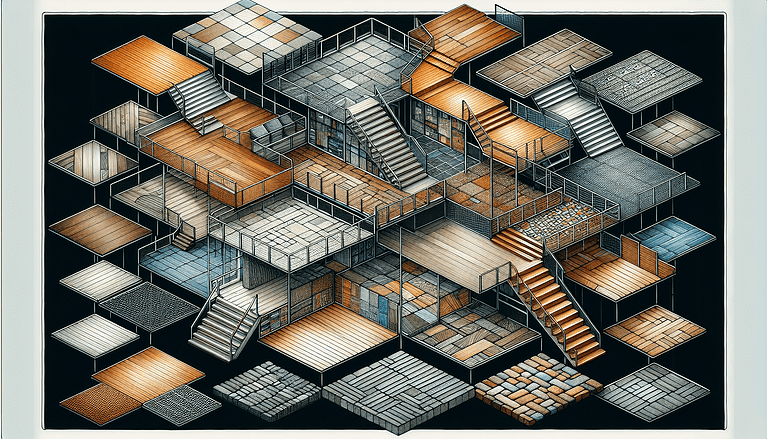

- Comprehensive solutions: Conveyco offers various vertical storage solutions, from manual systems like pallet racking and mezzanines to advanced automated systems like ASRS and AMRs.

- Space optimization: Their focus on vertical storage helps businesses maximize warehouse space utilization without expanding facilities.

- Customization: They emphasize tailoring solutions to specific business needs, considering factors like inventory characteristics and order profiles.

- Expertise: Conveyco demonstrates in-depth knowledge of various warehouse technologies and best practices.

- Safety focus: Their solutions aim to enhance workplace safety by reducing clutter and minimizing manual handling.

- Efficiency improvements: The implemented systems can increase productivity, reduce labor costs, and improve order fulfillment speed.

- Future-oriented: They consider scalability in their solutions, allowing for business growth.

Cons

- Potential high initial costs: Implementing advanced vertical storage systems, especially automated ones, likely requires significant upfront investment.

- Complexity: Some advanced systems may require specialized training for staff and potentially complex integration with existing systems.

- Dependence on technology: Highly automated solutions could lead to operational disruptions if technical issues occur.

- Potential overengineering: Some of the advanced solutions might be unnecessary for businesses with simpler needs.

- Implementation challenges: Transitioning to new vertical storage systems could temporarily disrupt operations.

Summary

Conveyco appears to offer a wide range of vertical warehouse storage solutions that can significantly improve space utilization, efficiency, and safety in warehouse operations. They seem particularly well-suited for businesses looking to optimize their warehouse space and are open to both manual and automated solutions.

Bonus Pick (Italy). Modula

Modula specializes in automated vertical storage solutions designed to maximize vertical space utilization while saving floor space. Their systems are adaptable to various industries and product types.

Pros

- Space optimization: Modula’s solutions efficiently use vertical space, potentially reducing the need for warehouse expansion.

- Customization: Their systems offer high levels of customization in height, tray size, load capacity, and configuration options.

- Efficiency: The “goods-to-man” principle reduces operator movement, potentially increasing productivity and reducing picking errors.

- Versatility: Solutions can be adapted for various industries and product types, making them widely applicable.

- Advanced technology: Features like the Eagle-toothed belt transmission system and visual aids (laser pointers, LED bars) demonstrate a commitment to innovation.

- Ergonomics: The design focuses on operator comfort and safety, which could lead to improved workplace satisfaction and reduced injuries.

- Heavy load capacity: Ability to handle loads up to 990 kg, suitable for industries dealing with heavy items.

- Track record: With over 35 years of experience, Modula has a proven history in the industry.

Cons

- Initial investment: As with most automated systems, the upfront cost could be significant.

- Complexity: The high level of customization and advanced features may require specialized training for operators and maintenance staff.

- Dependence on technology: Reliance on automated systems could lead to significant disruptions if technical issues occur.

- Potential overengineering: Modula’s advanced features might be unnecessary for businesses with simpler storage needs.

- Unclear scalability: While customizable, it’s not explicitly stated how easily these systems can be scaled as a business grows.

- Integration challenges: Implementing such a system may require significant warehouse processes and layout changes.

- Maintenance considerations: Advanced systems often require specialized maintenance, which could be an ongoing cost.

Summary

Modula offers sophisticated automated vertical storage solutions that can significantly improve space utilization, efficiency, and accuracy in warehouse operations. Their systems seem particularly well-suited for businesses dealing with a variety of product types, including heavy items, and those looking to significantly upgrade their warehouse technology.