Vertical Storage Solutions: Powerful Ideas for Maximizing Space

What if you could double your warehouse space without adding a square foot? Welcome to Vertical Storage Solutions.

Introduction

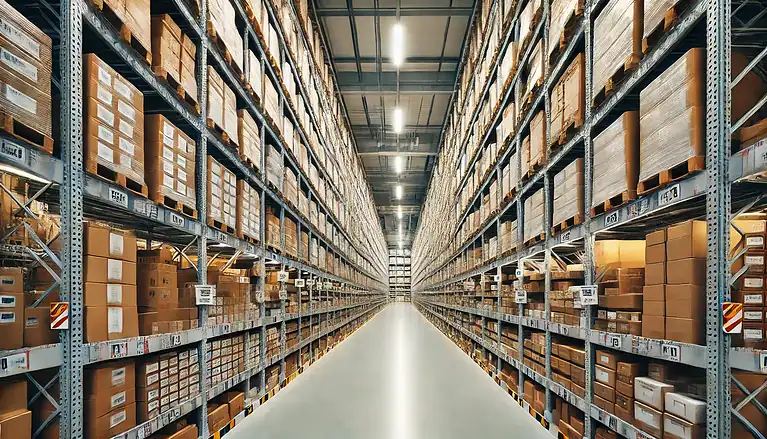

In warehousing and logistics, space is money. As e-commerce grows and products multiply, warehouse managers face a growing problem: more to store in less space. Vertical storage solutions are the game changer for maximizing warehouse capacity.

Vertical storage solutions are innovative systems and technologies that use a facility’s vertical space to increase storage density dramatically. Instead of spreading out, these solutions go up, turning unused air space into inventory real estate.

From automated lift modules to towering pallet racks, vertical storage is changing how modern warehouses work.

The benefits of going vertical go way beyond just fitting more in your warehouse. Vertical storage solutions give you better inventory accuracy, faster pick times, safer workers, cost savings, and easy access.

In this post, we’ll look at 7 of the latest vertical storage solutions that are helping warehouses worldwide optimize their space, streamline their operations, and boost their bottom line.

Whether you’re bursting at the seams in your current facility or designing a new warehouse, these tips will help you maximize your vertical space and take your storage to new heights.

Why Vertical Storage in Warehousing

Before getting into the solutions, let’s understand why vertical storage is important.

Space Utilization and Cost Savings

The most obvious benefit of vertical storage is space utilization. By using the full height of your warehouse, you can:

Double or more your storage capacity in some cases

Delay or eliminate the need for costly facility expansions

Reduce real estate costs by using existing space

Reduce energy costs by reducing the footprint that needs to be heated, cooled, and lit

Vertical storage solutions also eliminate wasted space and maximize storage capacity and productivity.

Inventory Management

Vertical storage solutions often come with advanced inventory management features:

Better visibility and organization of stock

Less time searching for items

Improved inventory accuracy and fewer errors

Better stock rotation and less obsolete inventory

Safety and Accessibility

Reaching higher can make your warehouse safer:

Less manual handling and fewer lifting injuries

Less forklift traffic in aisles

Ergonomics with items brought to optimal picking height

Better organization means less trip hazards

Vertical storage solutions also reduce the need for employees to climb ladders or use forklifts, so there’s less risk of accidents.

Operational Efficiency

Vertical storage can simplify your warehouse operations:

Faster pick and putaway times

Higher order fulfillment rates

Better labor utilization

Automation potential

As you can see, the benefits of vertical storage go way beyond space. These solutions can change your warehouse operation, bringing cost savings, efficiency, and safety.

7 Vertical Storage Solutions

Now let’s get into the seven most advanced vertical storage solutions:

Solution 1: Vertical Lift Modules (VLMs)

Vertical lift modules (VLMs) are enclosed systems of vertically arranged trays, an extraction platform, and controls for high-density storage solutions.

Key benefits:

85% space savings

Ergonomics and safety

Faster pick and more accurate

For small to medium-sized items, parts storage, and order-picking.

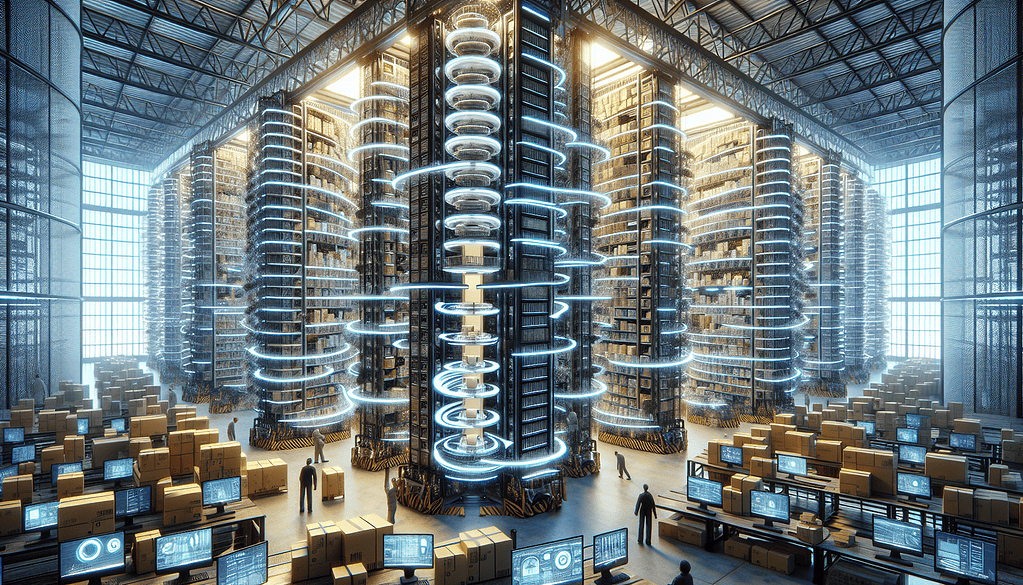

Solution 2: Automated Storage and Retrieval Systems (AS/RS)

AS/RS are computer-controlled systems that automatically place and retrieve loads from defined storage locations and retrieve items from vertical warehouse storage racks, increasing productivity and reducing labor costs.

Key benefits:

High-density storage

Reduced labor costs

Inventory control

24/7 operation

For: Large warehouses with high volume throughput need precision inventory control.

Solution 3: Mezzanines

Mezzanines are elevated platforms that create an additional floor in your warehouse space. Vertical height is key when optimizing warehouse storage when using mezzanines.

Key benefits:

Double usable floor space

Customizable to your needs

Cheaper than expansion

For: Warehouses with high ceilings and need for extra workspace or storage areas.

Solution 4: Vertical Carousels

Vertical carousels are a series of carriers that rotate vertically to deliver items to an access point.

Key benefits:

80% space savings

Faster pick and more accurate

Ergonomics

For storing and retrieving small to medium-sized items in height-restricted facilities.

Solution 5: Pallet Flow Racking

Pallet flow racking uses inclined rails and rollers to move pallets from the loading end to the picking end, providing easy access to individual pallets.

Key benefits:

High-density storage for palletized goods

FIFO inventory control

Reduced forklift travel

For: Warehouses with large quantities of similar products with high turnover.

Solution 6: Push Back Racking

Push-back uses inclined rails and carts to store 2 to 5 deep pallets. The STAK System is another example of an adjustable racking system that allows for vertical storage and saves floor space by eliminating dead space.

Key benefits:

High-density storage

LIFO inventory control

Space utilization

For: Warehouses with limited space and need for high-density storage of multiple SKUs.

Solution 7: Mobile Racking Systems

Mobile racking systems are mounted on motorized bases that move along tracks without requiring multiple aisles.

Key benefits:

50% space savings

Full access to all pallets

Adaptable to different load types

For: Cold storage facilities, archives, and premium space warehouses.

Each solution has its own benefits, and the best one for your warehouse will depend on your needs, products, and operation.

Vertical Storage in Your Warehouse

Moving to vertical storage solutions requires planning and execution. Here’s a guide to help you implement:

Assessing Your Warehouse’s Needs and Constraints

Calculate your current space utilization

- Identify bottlenecks in your current storage system

- Review ceiling height and floor load capacity

Vertical storage solutions can benefit the supply chain industry in terms of inventory control and storage efficiency. Questions to ask include:

Product mix

Which items to store vertically

- Inventory turnover rates

- Operational requirements

- Picking and putaway processes

- Order fulfillment speed

Choosing the Right Vertical Storage Solution

Match solutions to your needs: product size and weight, inventory control strategy (FIFO vs LIFO), budget, and ROI expectations

Scalability: Find solutions that can grow with you, understand future product lines or changes in inventory

Vendor options: Research different manufacturers and their history and request demos and site visits to see systems in action

Integration with Existing Systems

Warehouse Management System (WMS) integration: Make sure your chosen solution can integrate with your current WMS and understand your plan for software updates or upgrades

Staff training: Develop a full training program for your team with a phased implementation to allow for learning curves

Workflow changes: Redesign your layout to accommodate new systems and update picking and putaway procedures

Measuring the Impact

To see if your vertical storage solution is working:

KPIs

Space Utilization: Measure the increase in storage

Order Fulfillment Speed: Track the reduction in picking time

Inventory Accuracy: Monitor the reduction in picking errors

Labor Productivity: Measure units per labor hour

Cost Savings: Calculate the reduction in operational costs

Case Study: ABC Electronics’ Vertical Storage

ABC Electronics installed Vertical Lift Modules for their small components. They:

70% increase in storage

65% reduction in picking time

99.9% inventory accuracy

ROI in 18 months

These results show what’s possible when vertical storage is done right.

The Future of Vertical Storage

As technology advances, the future of vertical storage looks increasingly innovative and efficient. Here’s a glimpse into what we can expect:

Emerging Technologies in Vertical Storage

- Artificial Intelligence (AI) and Machine Learning

- Predictive inventory management

- Automated replenishment systems

- Optimized storage allocation based on demand patterns

- Internet of Things (IoT)

- Real-time tracking of inventory movement

- Predictive maintenance for storage systems

- Enhanced security and environmental monitoring

- Robotics and Automation

- Autonomous mobile robots for picking and putaway

- Drone technology for high-level inventory checks

- Robotic arms for precise handling in high-density storage areas

- Augmented Reality (AR)

- AR-guided picking and putaway processes

- Virtual warehouse planning and layout optimization

- Enhanced training programs for warehouse staff

Predictions for the Industry

- Increased Integration of Vertical and Horizontal Systems

- Seamless combination of vertical storage with automated guided vehicles (AGVs)

- Holistic warehouse management systems controlling all aspects of storage and retrieval

- Sustainable Storage Solutions

- Energy-efficient vertical storage systems

- Use of recycled and eco-friendly materials in storage construction

- Integration with renewable energy sources

- Customization and Flexibility

- Modular vertical storage systems adaptable to changing inventory needs

- On-demand scalability to meet seasonal fluctuations

- Enhanced Safety Features

- Advanced sensors and AI for predictive safety measures

- Ergonomic designs to further reduce workplace injuries

Conclusion

Vertical storage solutions have proven to be game-changers in warehousing and logistics. By maximizing vertical real estate, these innovative systems offer a multitude of benefits:

Dramatically increased storage capacity

Improved inventory control and accuracy

Enhanced operational efficiency

Significant cost savings

Improved workplace safety and ergonomics

From Vertical Lift Modules to Mobile Racking Systems, the range of available solutions allows warehouses of all sizes and types to leverage their vertical space effectively.

As we look to the future, emerging technologies promise to make these systems even more intelligent, efficient, and integrated into overall warehouse operations.

Implementing vertical storage solutions requires careful planning and consideration of your needs, but the potential rewards are substantial.

You can transform your warehouse from a space constraint into a competitive advantage with the right strategy.

With vertical storage solutions, are you ready to take your warehouse to new heights? The future of efficient, space-maximizing storage is here, and it’s time to embrace it.

Ready to explore how vertical storage solutions can transform your warehouse operations? Contact Warehouse Whisper for a personalized consultation.

We can help you assess your facility’s vertical storage potential and provide a list of qualified vendors to support your goals.