Powerful Voice Picking Technology – The Ultimate Guide for 2026

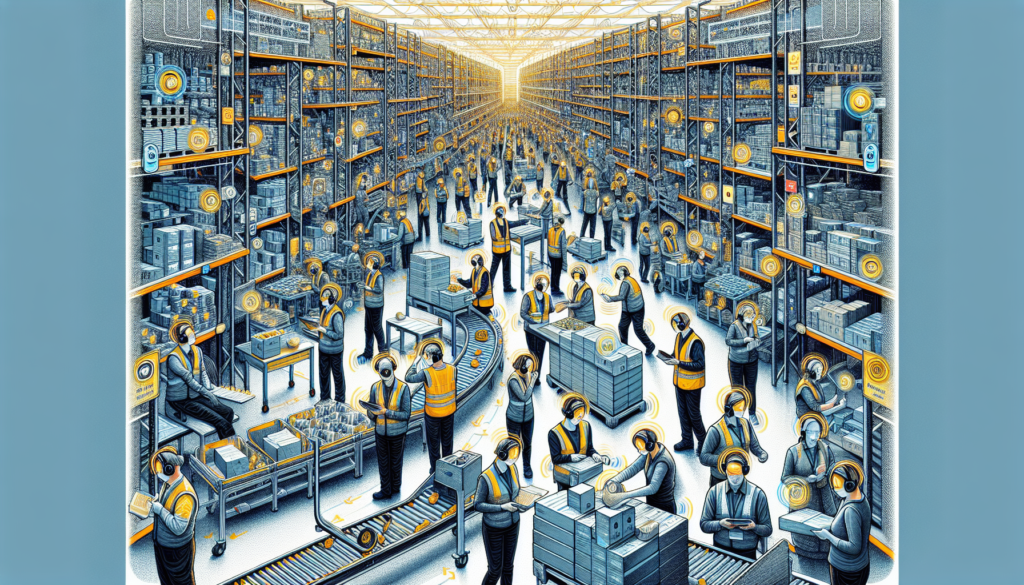

In the ever-competitive world of logistics and fulfillment, warehouse efficiency is no longer optional—it’s essential. One of the most transformative innovations in this space is voice picking technology.

This hands-free, eyes-up solution empowers warehouse associates to move faster, make fewer errors, and stay safer, resulting in reduced costs and happier customers. Whether you’re operating a high-volume e-commerce warehouse or a temperature-controlled distribution center, voice-directed picking is a game-changer.

Table of Contents

🧠 What Is Voice Picking?

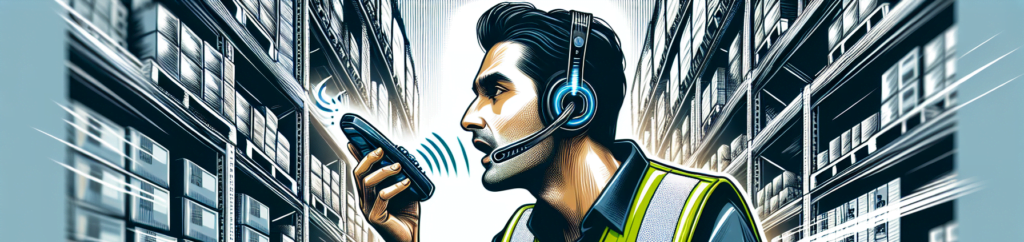

Voice picking—also known as voice-directed warehousing or pick-by-voice—is a system where workers use headsets and microphones connected to a voice platform that integrates with your Warehouse Management System (WMS).

Instead of relying on paper lists, RF scanners, or mobile devices, workers receive spoken instructions that guide them to the correct product and location.

🗣️ “Pick item 4472 from bin B6, confirm quantity.”

They then respond using simple voice commands like “Picked five” or “Confirmed”. The system verifies the input, updates inventory, and provides the next instruction—all without workers taking their eyes off the warehouse floor or their hands off the products.

Quick Story: My first experience with voice picking was quite embarrassing. I was interviewing for a job and touring the warehouse. I was trying to be impressive by smiling and talking to the associates working.

📈 Key Benefits of Voice Picking Technology

| Advantage | Impact |

|---|---|

| 👐 Hands-Free Workflow | Increases speed and keeps workers focused on task, not on screens or paper |

| 🎯 99.99% Accuracy | Reduces mispicks and returns, ensuring better customer satisfaction |

| 🔐 Improved Safety | Workers stay heads-up, improving awareness of surroundings |

| ⏱️ Reduced Training Time | Intuitive system enables seasonal and temp workers to perform quickly |

| 💰 Lower Operating Costs | Optimizes labor, reduces errors, and minimizes walking distance |

🔍 How Does Voice Picking Work?

Here’s a typical voice-picking workflow:

WMS Integration: Orders are downloaded from your warehouse management system.

Task Assignment: Pick tasks are distributed to users via voice-enabled mobile devices.

Instruction Delivery: Workers wear headsets and receive step-by-step verbal commands.

Product Confirmation: Workers confirm item codes, quantities, and bin numbers verbally.

System Update: Inventory levels are updated in real time, and the next task is issued.

Modern systems use natural language processing and are optimized for noisy warehouse environments, ensuring accurate voice recognition even around conveyors and forklifts.

⚖️ Voice Picking vs. Traditional Picking Methods

| Feature | Voice Picking | Traditional Picking |

|---|---|---|

| Training Time | Minimal (hours) | Moderate (days to weeks) |

| Error Rate | ~0.01% | 1–3% |

| Fulfillment Speed | Faster due to hands-free operation | Slower due to manual scanning |

| Safety | Higher (eyes-up workflow) | Lower (eyes-down, paper/RF) |

| Scalability | High | Moderate |

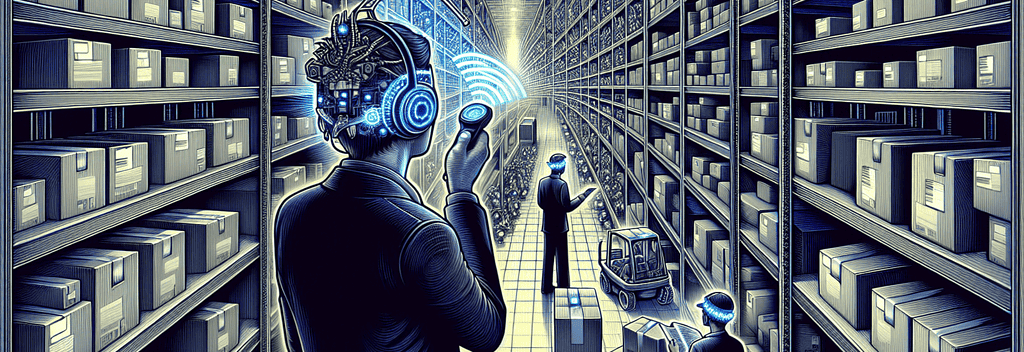

🤖 Integrating Voice with Other Technologies

Today’s leading warehouses are going multi-modal—combining voice with barcode scanning, RFID, smart glasses, and autonomous mobile robots (AMRs).

🔗 Voice + Barcode Scanning

Ideal for environments requiring dual confirmation

Boosts traceability and adds redundancy for compliance-heavy industries

🥽 Voice + Smart Glasses

Combines audio instructions with visual overlays

Especially helpful for complex assemblies or multi-line picks

📦 Voice + AMRs or Pick-to-Light

Voice can trigger actions from other systems, such as guiding robots or illuminating pick locations

📊 Real Results: Productivity and Accuracy

Companies using voice picking report:

25–35% boost in productivity

Up to 99.99% order accuracy

30–50% reduction in training time

50% fewer safety incidents related to inattention or distraction

📚 Case Example: Mission Health Systems

After implementing a voice-directed picking system, Mission Health Systems saw:

33% reduction in labor costs

99.8% order accuracy

Faster onboarding of temp workers during seasonal peaks

🏗️ Getting Started: Implementation Guide

Step 1: Assess Readiness

Do you already use a WMS or ERP?

Can your existing infrastructure support mobile devices and wireless connectivity?

Do your picking processes involve high SKU counts, multiple zones, or fast turns?

Step 2: Choose a Voice Provider

Top solutions in 2025 include:

Honeywell Voice (formerly Vocollect)

Zebra FulfillmentEdge with Voice

ZetesMedea Voice

Lucas Systems with Jennifer Voice

Ehrhardt + Partner LFS.VOICE

Step 3: Train Your Workforce

Use simple, intuitive voice commands (most systems support natural language)

Provide 1–2 hour onboarding sessions with role-play simulations

Let staff practice with non-live orders to build confidence

Step 4: Monitor and Optimize

Review pick paths and zone assignments

Adjust routes and workflows to reduce travel distance

Track KPIs like picks per hour, pick accuracy, and average training time.

🧠 Best Practices for Voice Picking Success

Standardize commands across all zones for easier training

Pilot before you scale—start in one zone or product family

Combine voice with automation like AMRs and conveyors

Use data to drive decisions: Analyze pick times, error rates, and inventory movements

Support seasonal staff with cheat sheets or demo videos integrated into devices

🤔 FAQs About Voice Picking Technology

What does voice picking cost to implement?

Prices vary by provider and scale but generally range from $2,000–$4,000 per user for hardware and software.

Can voice systems work in loud environments?

Yes. Modern systems are optimized for noisy warehouses using directional microphones and real-time noise filtering.

Is voice suitable for cold storage or freezer environments?

Absolutely. Voice systems excel in cold chain environments where gloves make touchscreens difficult to use.

Do I need Wi-Fi throughout my facility?

Yes. Voice systems require strong wireless coverage to sync tasks and updates with the WMS in real time.

🚀 Conclusion: Why Voice Picking Is a Must-Have in 2025

If you’re still relying on paper or handheld scanners for warehouse picking, you’re missing out on one of the most efficient, accurate, and scalable solutions available today.

Voice picking in warehouses is no longer just a trend—it’s a proven method for maximizing efficiency, reducing costs, and staying ahead of your competitors.

Case studies and success stories have illustrated the profound influence of voice-picking technology on warehouse operations, epitomized by companies like Frontier Distributing and Mission Health Systems, which have experienced marked enhancements in precision and efficiency.