Warehouse Lighting: Boost Safety, Savings, and Efficiency

Warehouse lighting is more than just a utility expense—it’s a key driver of safety, productivity, and cost savings. From outdated fluorescent bulbs to modern LED systems, the right lighting can reduce energy bills, improve visibility, and even boost worker morale. For warehouses looking to cut costs while improving performance, smart lighting upgrades are one of the easiest wins.

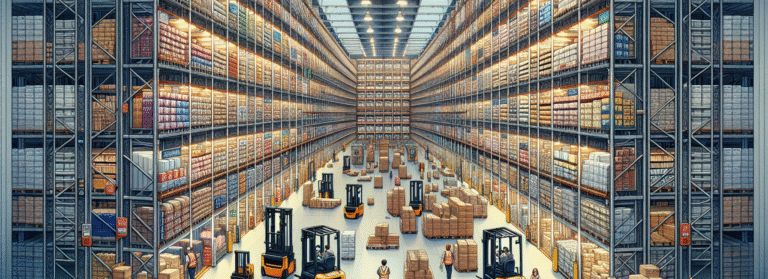

Why Warehouse Lighting Matters

Lighting has a direct impact on worker safety, picking accuracy, and energy costs. Poor illumination increases accident risks and slows productivity, while efficient lighting systems ensure clear visibility and help meet OSHA workplace safety standards.

7 Warehouse Lighting Upgrades That Cut Costs Fast

1. LED Lighting Conversion

Switching from fluorescent or metal halide bulbs to LEDs can cut energy use by up to 70%. LEDs also last longer, reducing maintenance costs and downtime for bulb replacement.

2. Motion-Sensing Lights

Installing motion detectors ensures lights are only used when areas are occupied. This reduces wasted energy in low-traffic aisles or storage zones.

3. Smart Lighting Controls

Warehouse lighting can be integrated with smart systems that adjust brightness according to the time of day or natural light availability. This automated approach ensures optimal visibility with minimal energy waste.

4. High-Bay Fixtures

High ceilings require specialized high-bay fixtures for even light distribution. Upgrading to efficient high-bay LEDs ensures consistent brightness across large warehouse floors.

5. Skylights and Natural Light

Incorporating skylights or solar tubes reduces reliance on artificial lighting during the day. This not only saves energy but also fosters a healthier and more natural work environment.

6. Emergency and Safety Lighting

Every warehouse needs reliable backup lighting for power outages and emergency exits. LED emergency lights ensure compliance while consuming far less energy than traditional systems.

7. Energy Audits and Rebates

Conducting an energy audit identifies opportunities for savings and may qualify your warehouse for government rebates. Rebates can offset upfront costs, making upgrades more affordable.

Benefits of Warehouse Lighting Upgrades

Lower operating costs through energy efficiency

Improved safety with brighter, consistent illumination

Increased accuracy in picking and inspections

Reduced environmental footprint with sustainable LED options

Boosted employee morale from well-lit, comfortable spaces

Challenges to Consider

Upfront investment in LED fixtures and smart controls

Disruption during installation if not planned properly

Training staff on smart lighting systems

Conclusion

Upgrading warehouse lighting is one of the simplest and most effective ways to reduce costs, enhance safety, and boost productivity. From LED high-bays to smart lighting controls, these investments quickly pay for themselves in energy savings and better working conditions. Warehouses that adopt modern lighting solutions not only lower expenses but also benefit from a brighter, safer, and more efficient workplace.