The Powerful Rise of Automated Warehouse Operations in 2026

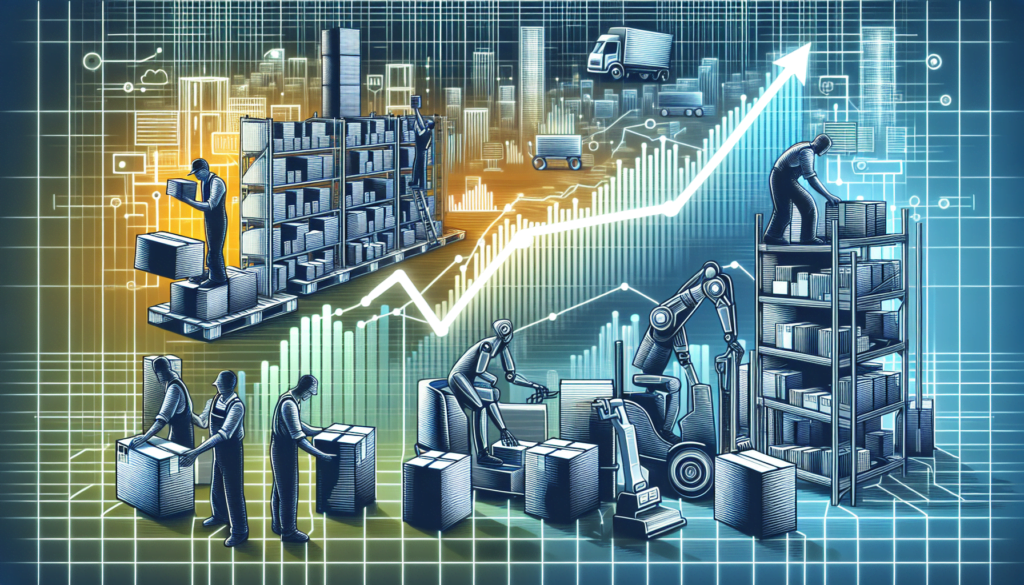

See how the logistics landscape is changing in 2024. This is due to the rise of automated warehouse operations. They’ve been unstoppable and where cutting-edge tech meets efficiency. They are reshaping the future of supply chains.

What does the rise of automated warehouses mean for your business?

In this article, we answer that critical question. We do it by looking at the game-changing tech driving warehouse automation and how easy it is to add. It offers big efficiency gains to the supply chain.

Discover the actionable insights businesses use to navigate this evolved automated warehouse landscape.

Key Takeaways

- Warehouse automation uses smart software, advanced robotics, and efficient equipment. Inventory and material handling undergo significant enhancements in speed and accuracy.

- AS/RS systems greatly boost storage capacity and improve order-picking precision. Automated systems like AGVs and robotic arms cut labor costs and errors. They also streamline shipping and receiving.

- Companies must plan well to implement warehouse automation. They must plan for integration and scalability, assess financial and operational impacts, and optimize warehouse layouts to ensure efficient space and automated system use.

Exploring the Essentials of Automated Warehouse Technology

Automation has greatly changed the supply chain. It is the critical infrastructure of updated distribution networks.

Many automated solutions are used in warehouses worldwide. They bring speed, precision, and productivity. These benefits were not seen before in handling and inventory control.

Imagine an intricately coordinated system where activities such as:

Receipt

Warehousing

Classification

Packaging

All are mechanized to reduce reliance on manual labor while enhancing procedural efficiency.

This shift transcends the simple substitution of human tasks. It rethinks warehouse management systems and creates a united and agile supply chain.

These advanced management systems empower warehouse operators. They help them maximize their premises’ use, refine workflows, and greatly cut costs. These changes drive companies to higher levels of excellence.

The Core Components of Warehouse Automation

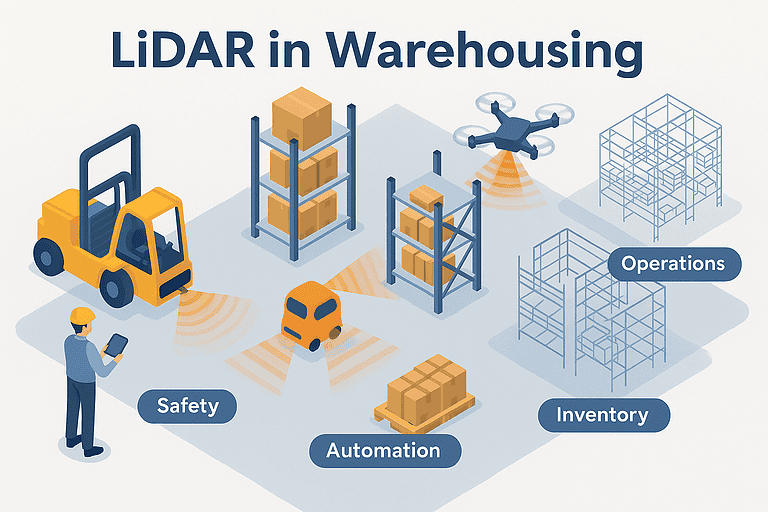

Warehouse automation’s backbone has three critical elements: advanced management systems, cutting-edge robots, and effective material handling gear.

Each aspect greatly improves warehouse operations. They range from the smarts of warehouse software. To the hard work of mobile robots. They also include the key role of conveyors. They also include the key role of storage. These things link processes.

Advanced Robotics in Action

Dive into the high-tech world of warehouse automation. Advanced systems are transforming manual labor. In these settings, robotic equipment is designed to reduce human movement. This boosts productivity and lets workers focus on complex tasks.

These technologies are pivotal. They speed up operations and cut labor costs. They do this while keeping their human teammates safe. They do this whether through agile AGVs or robust AMRs.

These automated solutions spring into action with cutting-edge software. Take Symbotic’s system. It orchestrates an army of robots. They fine-tune rehouse processes using AI-driven precision and flexibility. This surpasses conventional capabilities.

The culmination? A fully automated warehouse that functions with high accuracy and efficacy. This feat is impossible with only human labor.

Intelligent Software Solutions

A Warehouse Management System (WMS) is a command hub for warehouse automation. It supersedes manual processes by providing operational intelligence.

It provides instant inventory updates. They empower warehouse managers to deploy inventory systems. These systems track each item through its supply chain journey.

Make informed decisions using tools. Examples include barcode scanners for smooth Automatic Identification and Data Capture (AIDC).

Greatly improve both the accuracy and efficiency of various warehouse tasks.

This technology does more than ever. It boasts numerous functionalities designed to refine all aspects of warehouse operations.

They also automate many activities. These include making shipping labels and improving order fulfillment. This stride is significant. It makes workflows more efficient. It helps warehouse workers. It does this by simplifying hard logistics tasks. And it does it with better dependability and ease.

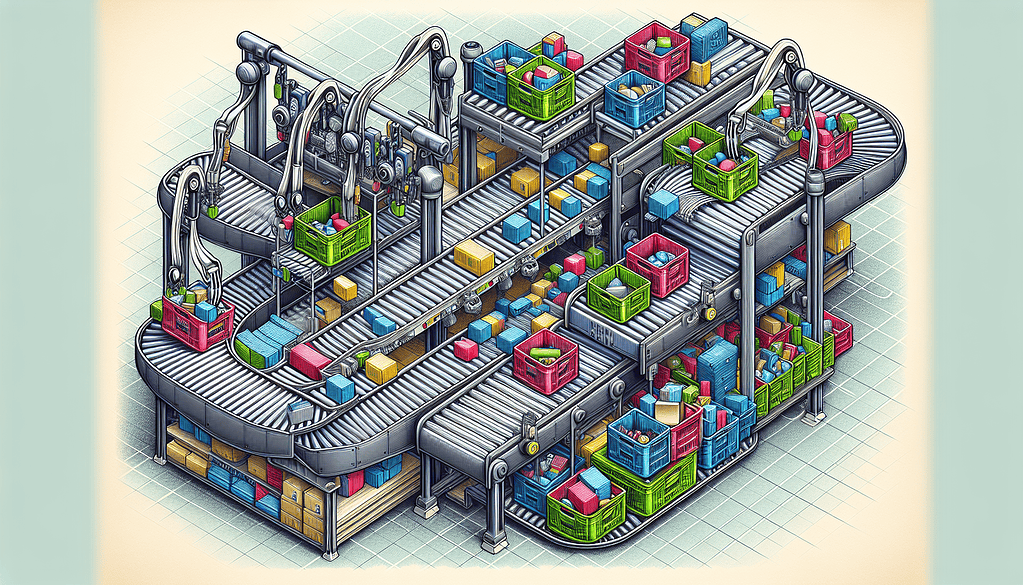

Seamless Material Handling Equipment

Material handling solutions are completing the trio of warehouse automation. They help move goods in the warehouse. Some examples of material handling solutions include:

AGVs travel along set paths. They reliably carry goods to storage or the shipping dock.

Conveyor systems transport goods along a fixed path. They allow continuous movement and efficient sorting.

Robotic arms, which can pick and place items with precision and speed.

These systems animate the idea of seamless logistics. They send each item to its exact destination. This could be a storage bin or an outbound truck. They do this with little human help.

But it’s not just about going from point A to point B. It’s about doing this with great speed and efficiency.

Automated sortation systems use cutting-edge technologies, like RFID and barcode scanners. They ensure that sorting and storage are not just fast but also very accurate.

These systems are the quiet workhorses of the automated warehouse. They tirelessly ensure that every item is where it needs to be, when needed.

The Impact of ASRS

Automated storage and retrieval systems are a big advance. They boost both warehouse space use and efficiency.

These advanced systems use the unused vertical area to increase capacity greatly. They allow for more compact storage, reducing the warehouses’ physical footprint.

The shift is from traditional shelving and open aisles to these automated, high-density solutions. It reduces space needs and reliance on manual labor.

These state-of-the-art automated storage and retrieval technologies are instrumental beyond mere space conservation. They play a crucial role in diminishing errors.

Integrating such technology improves precision in inventory management and order-picking accuracy. These are key factors in avoiding expensive blunders that can harm customer satisfaction.

These advanced systems boost supply chain flexibility. They equip it to adapt quickly to changes in e-commerce markets. This ensures optimal and smooth operations.

Warehouse Processes Through Automation

Automation has revolutionized warehouse efficiency. It has improved resource use and led to big cuts in costs. These cuts affect the whole supply chain.

This shift from manual tasks to automated systems boosts warehouse throughput. It also cuts operating expenses and eases labor shortages.

Streamlining Picking and Packing

Warehouse operations are changing. Automation is being integrated into picking and packing. Using Automated Storage and Retrieval Systems (AS/RS) cuts labor needs. This helps with lean inventory management. Lean inventory management is cost-effective.

Robots now handle many functions. They store items and restock them. This has led to a big upgrade. Orders receive swift and precise processing.

The introduction of robotics into warehouse environments signals:

A shift in workforce dynamics

Improved precision throughout operational procedures

Advanced safety mechanisms integrated within machines

Cooperative efforts between robots and human staff to reduce errors

Assurance that customers consistently receive accurate orders

Enhanced automated pick-and-pack capabilities often surpass client anticipation, setting new warehouse productivity benchmarks.

These systems boost warehouse efficiency a lot. They raise standards in every area.

Enhancing Shipping and Receiving

Automation’s influence permeates the shipping and receiving processes for peak efficiency. Automated systems have real-time package tracking. It ensures that goods are delivered faster and more precisely. It virtually eliminates loss or damage during transit.

This integration joins warehouse automation and transportation management software. It’s a game-changer. It boosts logistics operations to new efficiency levels.

Automation has had a big impact on shipping and receiving. We’ve seen this in examples like Ocado’s automated warehouse. It fills orders at a pace that sets the industry benchmark for speed.

Walmart’s barcode scanning is automatic. It ensures that inventory data is accurate and items are shelved quickly. This enhances speed and reliability. Customers have quick, error-free deliveries. They also get the satisfaction that cements loyalty.

Strategies for Implementing Warehouse Automation

Embracing warehouse automation requires a thoughtful plan. It must be strategic to ensure a smooth transition. Businesses should focus on scalability and integration. New systems should be added to current operations without any interruptions.

Studying new commercial models, such as Robots-as-a-Service (RaaS), could make it cheaper for companies. They could then adopt these automation technologies.

Assessing Your Automation Needs

The initial step when considering automation is devising a comprehensive implementation plan. Craft this plan with help from an automation specialist. It will address costs, training, and system improvement.

Industries face labor shortages. Autonomous mobile robots (AMRs) let human workers focus on higher-level tasks. This ensures that automation complements, rather than replaces, human labor.

Training and change management are also critical components of the transition. New automated systems are coming online. Employees must have the knowledge and skills to maximize their potential. This will ensure that the human side of warehouse operations evolves with technology.

Planning for Integration and Scalability

Ensuring warehouse automation fits with current systems is crucial. It keeps operations uninterrupted. But the focus shouldn’t be solely on today.

Preparing by planning scalable automation solutions can help a business stay ready for growth. It prevents costly changes later. Adopting a modular strategy when rolling out systems like Automated Storage and Retrieval Systems (AS/RS) offers flexibility.

It allows the systems to meet changing needs. They do so without losing sight of the budget and efficiency.

Cost-Benefit Analysis of Automated Warehouses

Investing in warehouse automation requires a big monetary commitment. You must thoroughly evaluate the initial cost to buy, install, and maintain it. You must weigh this cost against the future, lasting savings on labor and day-to-day costs.

Companies must consider potential risks. These include system failures and the constant need for technical help. They must do so to confirm that the benefits truly outweigh these costs.

The Future of Automated Warehouses

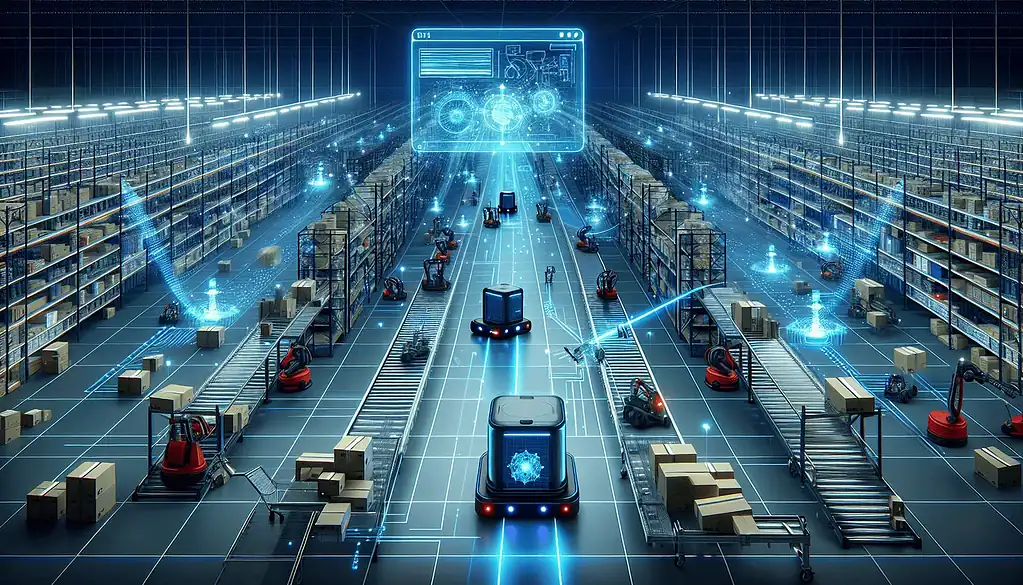

The future of supply chain management is linked to automated warehouses. AI and machine learning are merging with robotic technology. They will bring a revolutionized level of efficiency. Self-driving systems will be able to optimize paths and tasks for moving goods.

Envisioned as an integral component within a vast network, the warehouse that is yet to come will:

Incorporate IoT technologies

Apply real-time data analysis

Synchronize functions seamlessly

Improve transparency throughout every segment of the supply chain

Balancing Automation with Human Oversight

Even with progress in automation, humans play a crucial role in warehouse operations. They can work, oversee processes, and solve complex issues.

The goal isn’t to replace human workers. It’s to create synergy between automated systems and human skills. This collaboration aims to boost productivity. It aims to foster an environment where efficiency thrives in warehouses.

Optimizing Your Warehouse Layout for Automation

Refining a warehouse’s configuration is critical to the advantages of automation. This task needs a deep look at existing and expected needs. It also needs to be a wise choice of suitable automation. And thorough testing to confirm the design works as intended.

The goal is to use the facility’s space better. Also, to expand its storage. And to ensure that automated systems work well.

Summary

In conclusion, the rise of automated warehouses shows the power of technology. It revolutionizes industry practices. Businesses and warehouse operators continue to embrace these innovations. The era of the smart warehouse is not just coming—it is here.

Frequently Asked Questions

What is warehouse automation, and why is it important?

Utilizing technology in warehouse automation is essential for streamlining warehouse operations. It helps prove efficiency, cuts labor costs, makes better use of space, and boosts productivity, which results in reduced expenses.

How do Autonomous Mobile Robots (AMRs) improve warehouse operations?

Autonomous Mobile Robots boost warehouse efficiency by cutting employee transit and labor costs and raising productivity and safety standards.

The robots have advanced navigation systems. They can move through facilities on their own while avoiding obstacles. They can also safely work with human colleagues.

What role does a Warehouse Management System (WMS) play in an automated warehouse?

A Warehouse Management System (WMS) is key to an automated warehouse. It boosts efficiency. It manages inventory by optimizing workflows and providing instant data. It also interfaces easily with various systems and replaces manual tasks through automation.

Can warehouse automation help with labor shortages?

Automating warehouses can ease labor shortages by handling repetitive tasks. This lets employees focus on more complex work, which can help address the challenges posed by labor shortages.

Are there financial help options available for businesses looking to install warehouse automation?

Companies can explore economic strategies. They include Robots-as-a-Service and leasing. These options reduce financial outlay. They might qualify for various subsidies and grants that ease the upfront costs. Such financial avenues can help businesses successfully install warehouse automation.