Smart Warehouse: How Connected Tech Redefines Logistics

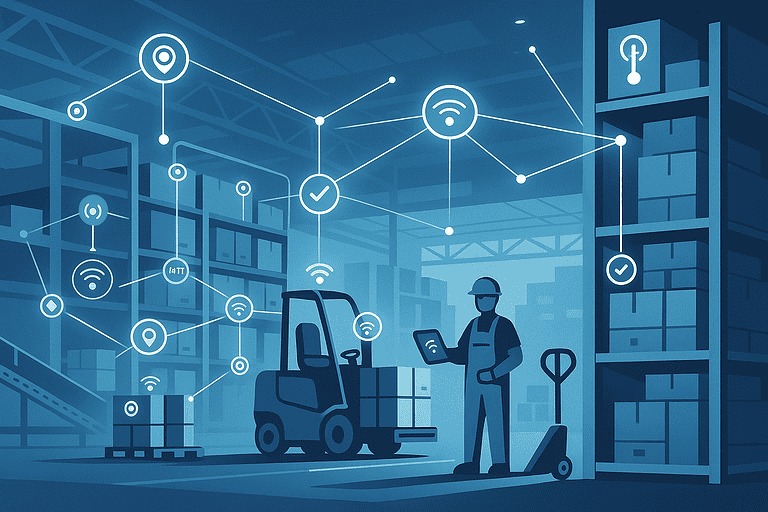

A smart warehouse isn’t just a storage facility—it’s a connected ecosystem where AI, IoT, and automation work together to improve speed, accuracy, and cost efficiency. By leveraging real-time data, robotics, and predictive analytics, smart warehouses help businesses meet rising customer expectations and adapt quickly to supply chain challenges.

What Is a Smart Warehouse?

A smart warehouse is a digitally enabled facility that integrates advanced technologies such as AI, IoT sensors, robotics, and cloud-based WMS. Unlike traditional warehouses that rely heavily on manual labor and isolated systems, smart warehouses connect every part of the operation for seamless efficiency.

7 Ways to Transform Operations

1. Real-Time Inventory Visibility

IoT sensors and RFID tags provide constant updates on inventory movement. Managers can see stock levels instantly, reducing errors and delays.

2. Improved Picking Accuracy

Smart warehouses utilize technologies such as voice picking and pick-to-light systems to guide workers. This reduces human error and boosts fulfillment speed.

3. Automation of Material Handling

Robotics and autonomous mobile robots (AMRs) handle repetitive transport tasks, freeing workers for higher-value activities and improving safety.

4. Predictive Maintenance

Sensors on conveyor belts, forklifts, and machinery detect early signs of failure, enabling proactive repairs and reducing costly downtime.

5. Energy Efficiency and Sustainability

Smart energy management systems optimize the use of lighting, HVAC, and equipment. Combined with green warehousing practices, this reduces both costs and carbon footprint.

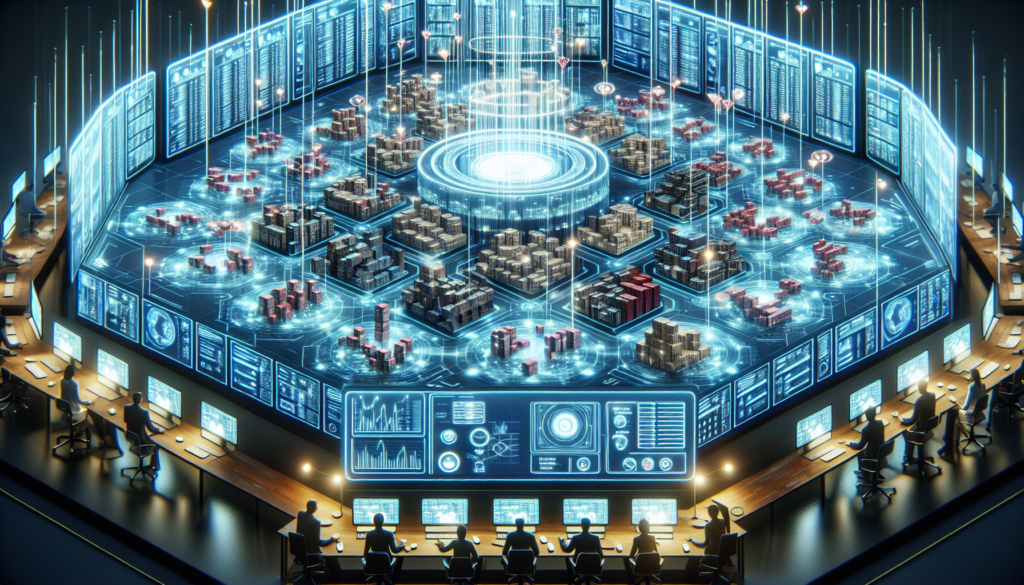

6. Cloud-Connected WMS & Analytics

Smart warehouses integrate WMS with advanced analytics to forecast demand, automate replenishment, and improve supplier coordination.

7. Enhanced Worker Safety

Wearables and AI-driven cameras monitor safety compliance, while automated systems handle hazardous tasks, improving the workplace safety culture.

Real-World Examples

Amazon utilizes robotics and AI-driven systems in its fulfillment centers to optimize picking and minimize the need for human labor.

DHL leverages IoT and 5G connectivity to pilot smart warehouses in Europe.

Walmart utilizes smart forecasting to ensure product availability during periods of high seasonal demand.

The Future of Smart Warehousing

Looking ahead, smart warehousing will continue to evolve with:

5G connectivity for real-time robotics control.

Digital twins for simulation and planning.

Blockchain integration for supply chain transparency.

Dark warehouses run almost entirely by automation.

Conclusion

The smart warehousing is no longer just a concept—it’s the future of logistics. By connecting robotics, IoT, and AI, businesses can achieve faster fulfillment, lower costs, and safer workplaces. Early adopters of smart warehousing will gain a competitive edge in 2025 and beyond.