Warehouse Ergonomics: 10 Powerful Strategies for 2026

Is your warehouse a backache for your workers? Discover how smart warehouse ergonomics can transform your facility into a haven of productivity and worker well-being. It’s time to say goodbye to workplace injuries and hello to peak performance!

Warehouse ergonomics isn’t just about comfortable chairs or fancy equipment—it’s the secret weapon revolutionizing the logistics industry. In today’s fast-paced warehouse environments, where every second counts, ergonomics ensures worker safety and operational efficiency.

But what exactly is warehouse ergonomics? Simply put, it’s the science of designing the workplace to fit the worker, rather than the other way around. It involves optimizing tasks, tools, and environments to reduce physical stress on the body and enhance overall performance.

Warehouse ergonomics reduces injuries, improves productivity, and boosts morale. Here’s how to make it work in 2025.

Ergonomic Risk Factors: The Silent Troublemakers

Warehousing has its own set of ergonomic booby traps. Knowing what to look for plays a pivotal role. Here are the critical ones:

Repetitive Motions: Think about that guy who’s been order picking the same way for 10 years straight. His wrists probably have a bone to pick with him.

Awkward Postures: Have you ever seen someone twist like a pretzel to reach a high shelf? That’s a one-way ticket to Backache City.

Force: Heavy lifting is part of the job, but too much too often? That’s asking for trouble.

Vibration: Forklift operators, I’m looking at you. Constant vibration can lead to all sorts of issues down the road.

Temperature Extremes: Cold or blazing hot environments stress the body.

Pro Tip: Perform a walkthrough of your warehouse considering these factors. You’ll start seeing risks you never noticed before.

Workplace Injuries: The Unwelcome Guests

Nobody wants workers injured in their workplace, but they happen. Here’s what we’re up against:

Sprains and Strains: The most common culprits. Often from lifting, reaching, or repetitive motions.

Back Injuries: The bane of warehouse workers everywhere. It can range from minor aches to serious, long-term problems.

Shoulder and Neck Issues: Often from looking at high shelves or hunching over workstations.

Carpal Tunnel Syndrome: This is especially common in jobs with repetitive hand movements.

Slips, Trips, and Falls: These are not strictly ergonomic but are often related to poor workspace design.

Real Talk: I once met a warehouse veteran who could predict the weather with his bad shoulder. Funny, sure, but also a stark reminder of the long-term impact of workplace injuries.

Occupational Safety: More Than Just Hard Hats

Occupational safety is the big picture that ergonomics fits into. It’s about creating a culture where safety is as natural as breathing, reducing safety risk. Key aspects include:

Safety Training: Regular, engaging, and relevant. It’s not just a boring video on day one.

Personal Protective Equipment (PPE): The right gear for the right job and wearing it.

Clear Safety Protocols: Written down, communicated clearly and followed consistently.

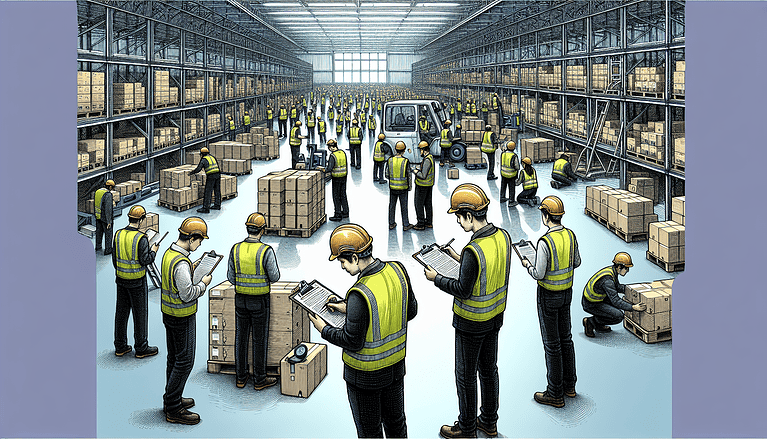

Regular Safety Audits: Because what gets measured gets managed.

Open Communication: Where workers feel comfortable reporting safety concerns without fear.

I remember a warehouse that started a “Safety Superhero” program. Cheesy? Yes. Effective? Absolutely. People started taking safety seriously when it became part of their identity.

Prevent Workplace Injuries: An Ounce of Prevention…

Preventing injuries is always better (and cheaper) than dealing with them afterward. Here’s how to stay ahead of the game:

Ergonomic Assessments: Regular checkups of workstations and processes.

Job Rotation: Mix it up to prevent repetitive strain injuries.

Stretching Programs: Start each shift with some simple stretches. It works wonders.

Proper Equipment: Invest in tools and machinery designed with ergonomics in mind.

Listen to Your Workers: They often know where the problems are before anyone else.

Encourage Rest Breaks: Short, frequent breaks can prevent fatigue-related injuries.

Ongoing Education: Keep ergonomics at the forefront of your mind with regular training and reminders.

True Story: I once worked with a warehouse that reduced its injury rate by 50% in one year. Our secret? We made injury prevention a team sport, with departments competing to see who could go the longest without an incident. It got everyone invested in safety.

10 Essential Warehouse Ergonomics Strategies for 2025

1. Master the Art of Proper Lifting

Let’s face it – lifting is a big part of warehouse work. But are your team members working smart to minimize injuries? Teaching proper lifting techniques isn’t just about avoiding injuries (though that’s huge). It’s about working smarter, not harder, and preventing musculoskeletal disorders.

Key tips:

Keep the load close to your body and avoid awkward body postures

Bend at the knees, not the waist, to prevent serious injuries

Avoid twisting while lifting and monitor worker fatigue levels

Never lift heavy items over shoulder height when order picking

Make the proper techniques part of your onboarding process. New employees will thank you (and so will their backs).

2. Invest in Ergonomic Equipment

You wouldn’t run a marathon in flip-flops, right? So why expect your team to work efficiently with subpar equipment? Ergonomic tools and equipment might cost more upfront, but they pay off big time in the long run.

Must-haves:

Adjustable workstations

Ergonomic hand trucks and pallet jacks

Anti-fatigue mats

One warehouse I worked with saw a 30% drop in reported back pain after introducing adjustable workstations. That’s a win in my book.

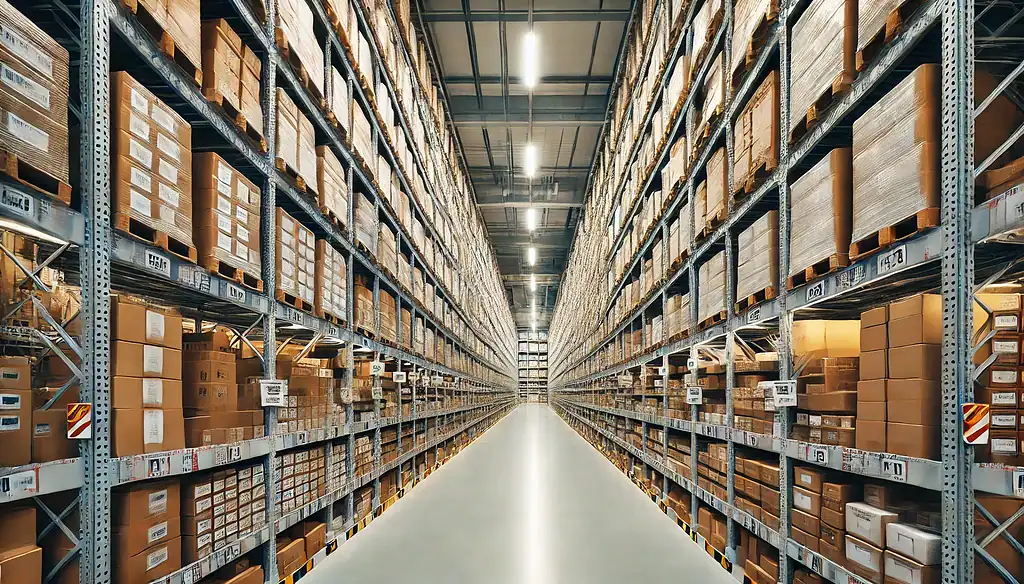

3. Optimize Your Layout

Have you ever watched a busy ant colony? They’ve got their layout down pat. Your warehouse should be just as streamlined. A well-thought-out layout reduces unnecessary movement and strain. An efficient storage system can improve the layout and reduce unnecessary movement and strain by optimizing the placement, picking, packing, and shipping processes.

Consider:

Placing frequently used items at waist level

Creating clear, wide aisles

Using gravity flow racks for easy access

Remember, a good layout isn’t set in stone. Be ready to adapt as your needs change.

4. Light It Up (The Right Way)

Poor lighting isn’t just a mood killer – it’s a productivity blocker and potential safety hazard.

Good lighting reduces eye strain and helps prevent accidents. But it’s not just about brightness.

Lighting tips:

- Use natural light where possible

- Install adjustable task lighting at workstations

- Reduce glare on computer screens

I once saw a warehouse boost order accuracy by 15% by improving lighting. Talk about a bright idea!

5. Encourage Movement and Stretching

Sitting is the new smoking, they say. But standing in one spot all day isn’t great either.

Encourage your team to start each shift with a stretching routine to warm up their muscles before working.

Try this:

Implement micro-break policies

Create stretch zones with guided exercises

Rotate tasks to vary movements

One creative warehouse manager I know started a “warehouse workout” challenge. It boosted morale and reduced repetitive strain injuries. Win-win!

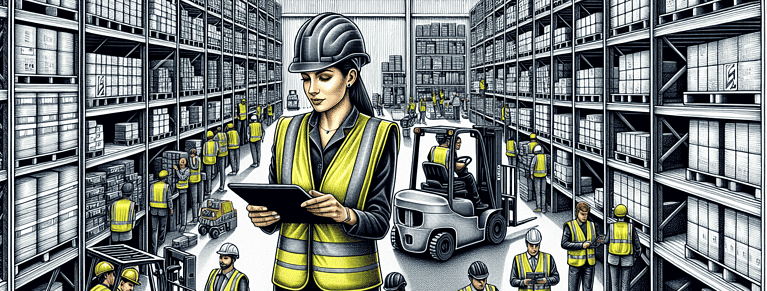

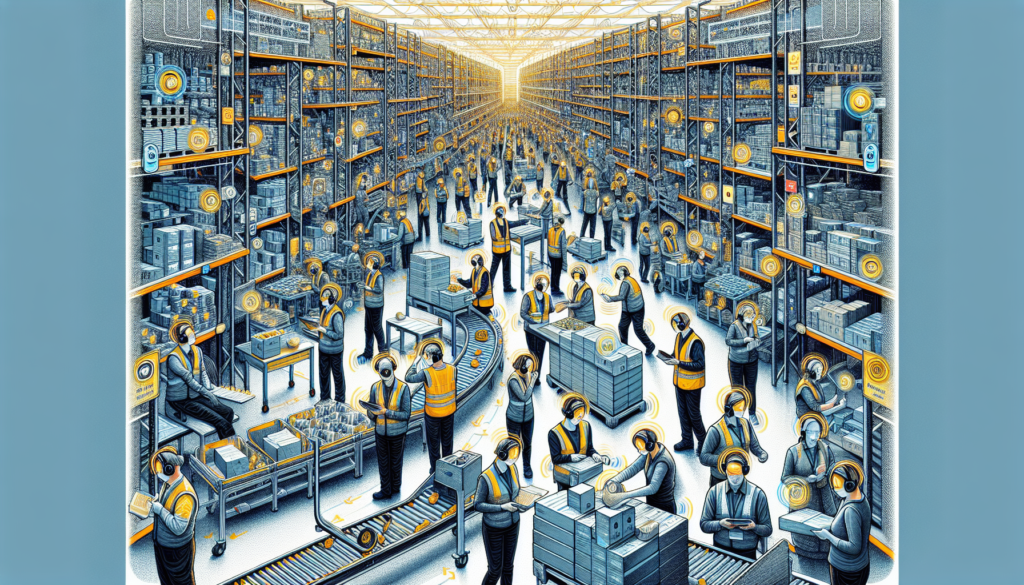

6. Leverage Technology for Ergonomic Wins

We’re living in the future, folks. Use it to your advantage!

There’s a ton of tech out there designed to make warehouses safer and more efficient.

Cool tech to consider:

Wearable devices that alert workers to poor posture

AI-powered workstation adjustments

VR training for safe lifting techniques

Don’t go overboard, though. The best tech complements your workers, not replaces them.

7. Create a Culture of Ergonomic Awareness

All the fancy equipment in the world won’t help if your team doesn’t buy in.

Make ergonomics part of your company culture via daily communication and awareness.

Proper training for warehouse equipment is crucial to ensure safety and prevent damage to storage racks and other materials.

How to do it:

Regular training sessions

Ergonomic tip of the week in team meetings

Reward programs for ergonomic innovations

Remember, your workers are your best source of ergonomic insights. They know where the pain points are – literally!

8. Don’t Forget the Little Things

Sometimes, it’s the small stuff that makes a big difference. Please don’t overlook the details when it comes to ergonomics.

You can’t improve what you don’t measure. Keep tabs on your ergonomic efforts and be ready to pivot when needed.

Ensure that everyone knows the safety record of the operation and why it is so important.

What to track:

Injury rates and types

Productivity metrics

Employee feedback

Use this data to refine your ergonomic strategies continually. It’s an ongoing process, not a one-and-done deal.

10. Make it a Team Effort

Last but not least, remember that ergonomics isn’t just a top-down initiative. Get everyone involved.

When the value of safety withing the organization is clear, all workers make better day-to-day decisions.

Ideas to try:

Form an ergonomics committee with reps from different departments

Host an ergonomic innovation contest

Conduct regular walk-throughs with staff to identify issues

Amazing things happen when everyone’s invested in creating a safer, more comfortable workplace.

Real-World Implementation: Beyond the Basics

You’ve got the strategies; now, let’s discuss implementing them. I remember visiting a warehouse in Detroit that tried to overhaul everything overnight. Spoiler alert: it didn’t go well. Change takes time, folks.

Start Small, Think Big

Pick one area to focus on first. Maybe it’s the packing station where folks always complain about sore shoulders. Make improvements there, track the results, and use that success to build momentum.

Ergonomic Audits: Not as Boring as They Sound

Regular check-ins are crucial. But forget clipboards and checklists. Make it interactive. I know a place that does “ergonomic scavenger hunts” where teams compete to spot potential issues. It’s effective and fun.

The Money Talk

Let’s face it – bosses love to see the bottom line. Track how your ergonomic changes affect productivity, sick days, and worker satisfaction. Numbers talk, and they’ll help you make the case for further improvements.

Tech: Friend or Foe?

We touched on tech earlier, but let’s get real. Not all fancy gadgets are worth their salt. I’ve seen warehouses blow their budget on high-tech solutions that gather dust. Start with the basics, then gradually introduce technology that truly adds value.

The Unexpected Benefits

Here’s something cool – good ergonomics often leads to unexpected wins. One warehouse I worked with saw a drop in product damage after improving their lifting techniques. It turns out that when people are comfortable, they handle items more carefully. Who knew?

Dealing with Resistance

Change isn’t always easy. Old-timers might insist, “We’ve always done it this way.” Patience is key. Show them the benefits, involve them in the process, and lead by example.

Beyond the Warehouse Walls

Ergonomics doesn’t stop when your employees clock out. Please encourage them to apply these principles at home, too. One company started a “Home Ergo” program, helping employees set up better workspaces for remote work. It paid off in reduced sick days and happier staff.

Continuous Learning

The world of ergonomics is always evolving. Stay curious. Attend workshops, join online forums, and network with other warehouse pros. I learn something new every time I step into a different facility.

The Long Game

Remember, creating an ergonomic warehouse is a journey, not a destination. It’s about creating a culture where safety and efficiency go hand in hand. It takes time, effort, and sometimes a bit of trial and error. But trust me, it’s worth it.

Wrapping Up

There you have it – 10 strategies to turbocharge your warehouse ergonomics game. Remember, it’s not about implementing everything at once. Start small, measure your progress, and build from there.

Your warehouse can be where efficiency meets comfort, and productivity goes hand in hand with workers’ well-being. It just takes a bit of creative thinking and a commitment to continuous improvement.

So, what’s your first move going to be? Whatever it is, your future self (and employees) will thank you. Here’s to happier, healthier, and more productive warehouses in 2024 and beyond!