#1 Quality Shelf for Warehouse Storage Solutions

Did You Know? 40% of Warehouse Space is Wasted Due to Poor Storage Solutions. Join our journey to streamline your warehouse with the ideal shelf for warehouse solutions.

Key Takeaways

- Warehouse shelving is essential for efficiency. It maximizes space using vertical storage systems and offers a variety of adaptable racking systems to suit different needs.

- Key types of shelving include pallet racking, wire decking, industrial shelving, and bulk storage racks. Each is designed for different loads and purposes, offering customization and expansion possibilities.

- Efficient warehouses integrate a mix of equipment and technologies, from automated systems and material handling tools to robust shelving and safety protocols, ensuring streamlined operations and compliance with safety standards.

Warehouse Shelving: A Comprehensive Guide

Consider the impact of a meticulously organized warehouse – it operates seamlessly, reduces workforce expenses, boosts efficiency, and greatly advances the organization.

What is the key to unlocking this level of performance? Warehouse shelving plays a pivotal role in streamlining warehouse functions.

These advantages are not limited to tidiness but also include optimizing the use of existing space.

Vertical storage systems allow for full use of high-rise ceilings by employing loftier racks or piling up containers.

This strategy is essential for enhancing space utilization and operational efficacy within a warehouse’s physical dimensions.

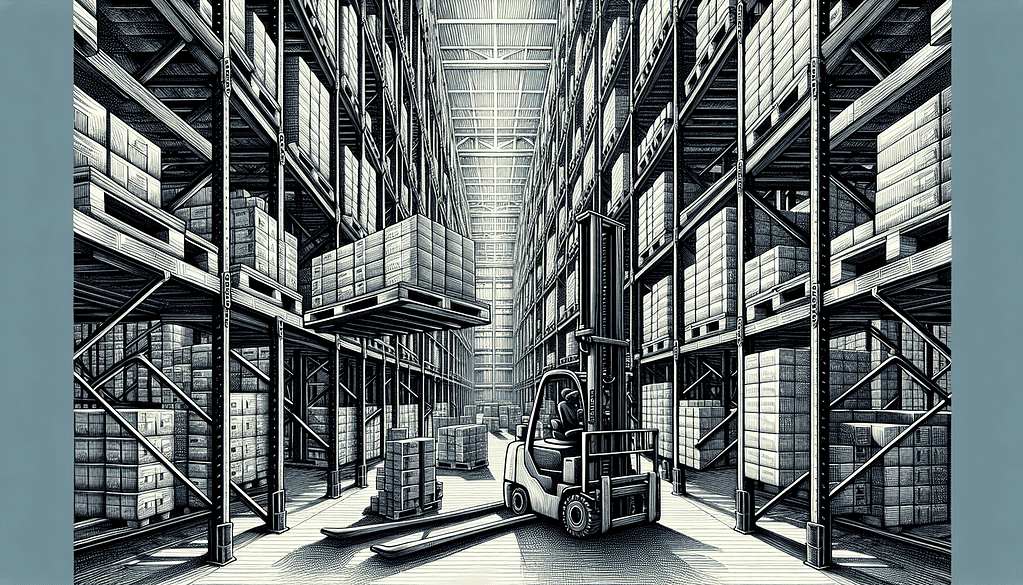

Pallet Racking: The Backbone of Warehouse Storage

Pallet racking serves as the critical backbone of a warehouse, offering solid and robust storage solutions that maintain organization.

These systems are resilient and versatile, enabling customization to meet specific infrastructure requirements while accommodating shifts in supply chain management needs.

Imagine reducing product damage by elevating items from the floor. Pallet shelving, with its reliable support structure, achieves this.

Dense storage alternatives such as drive-in, push-back, and pallet flow racks allow for greater inventory capacity within your existing space by minimizing aisle space.

Indeed, efficiency is epitomized here—a testament reflected in over a hundred years of consistent performance!

Wire Decking: Enhancing Safety and Versatility

Let’s delve into the subject of wire decking. Promoting safety and maintaining an orderly storage space is critical to reducing the likelihood of injuries and contributing to an organized facility where everything is tidy, free from clutter, and easy to see.

There are multiple benefits associated with using wire decking for shelving units:

- Safety: Wire decking is a barrier that prevents stored items from slipping through shelves, enhancing their stability.

- Flexibility: This type of decking works seamlessly with different shelving systems, thus broadening your options for organizing storage.

- Visibility: The design lets you quickly identify where items are on the shelves, simplifying inventory control procedures and fostering a safer work area.

Types of Warehouse Shelves: Finding the Perfect Fit

The variety of warehouse storage solutions is wide, from warehouse racks to shelving units suitable for manually stacked goods to pallet racks designed specifically for palletized items.

Determining the most appropriate system depends on your particular storage requisites.

Metal industrial shelving could be the answer for smaller inventory that requires manual handling.

If you’re seeking an organization solution for retail products or medical supplies, a range of specialized warehouse shelving systems is tailored to your needs.

Optimizing space by storing upwards shouldn’t be overlooked—selecting rack and shelving options that ensure safe vertical stacking capabilities is essential.

Industrial Shelving: Heavy-Duty Storage Solutions

Upon closer examination of industrial shelving, one finds that these formidable units are built to sustain an impressive load capacity of up to 1,850 pounds per shelf.

This remarkable strength is attributed to superior-quality steel, which enhances its durability and minimizes the risk of accidents in the work environment.

Industrial shelving stands out due to its adaptability across various applications.

Whether you opt for sturdy steel shelves or choose flexible rivet shelves known for their substantial weight-bearing capabilities, there’s a configuration suited for every requirement.

You can select closed metal shelving if your items need protection against dust and light exposure or prefer open-style shelving that offers increased visibility and easier access.

Bulk Storage Racks: Maximizing Floor Space

Consider the robust capabilities of bulk storage pallet racks designed to optimize available floor space through high-density storage arrangements.

Imagine warehouse pallet racks like push-back racking, adept at lessening the necessity for numerous aisles by facilitating the two-to-five-deep storage of pallets on both sides of a single aisle.

Drive-in racks provide an innovative solution where forklifts can maneuver right into the rack structure to place or retrieve goods—a perfect fit for housing substantial amounts of similar products.

For handling lighter loads, there’s also bulk rack shelving that provides both ease of relocation and flexibility with its adjustable features.

Add-On Units: Customizable and Expandable Storage

Should your business experience growth, the demand for increased storage capacity will likely follow.

Fortunately, augmenting your existing bulk storage racks and shelving systems with extra sections or tiers is straightforward.

These supplementary units provide an economical solution to expand your storage capabilities while remaining compliant with safety regulations.

Incorporating elements such as beams at floor level on pallet rack systems and clipless options in shelving allows you to accommodate palletized and non-palletized items, thus offering versatility for various storage needs.

Essential Storage Equipment for Efficient Warehouses

Warehouses depend on various storage, not just shelving, to enhance efficiency.

This includes cutting-edge automated options for system integration and data collection and mechanical automation tools that refine the workflow.

Imagine employing advanced technologies like IoT sensors and robotics within your warehouse environment. Such integration could dramatically reduce human errors while boosting overall operational efficiency.

Automated Storage and Retrieval Systems are pivotal in decreasing the need for manual labor in storing and retrieving goods—these systems accelerate processes and concurrently bring down workforce expenses.

Uprights and Beams: Building a Sturdy Storage System

Revisiting the essential elements of your setup, it’s important to recognize that uprights and beams form the backbone.

They play an integral role in establishing the strength and stability of warehouse shelving systems.

Regarding bulk racks, uprights are engineered to sustain up to 10,000 lbs per section, ensuring they can bear substantial weight.

Meanwhile, beams used within heavy-duty industrial shelving units employ a ‘Z’ design for enhanced reinforcement capable of handling concentrated loads.

These components also offer adaptability with their adjustable configurations on 1-12 inch centers, allowing flexible solutions.

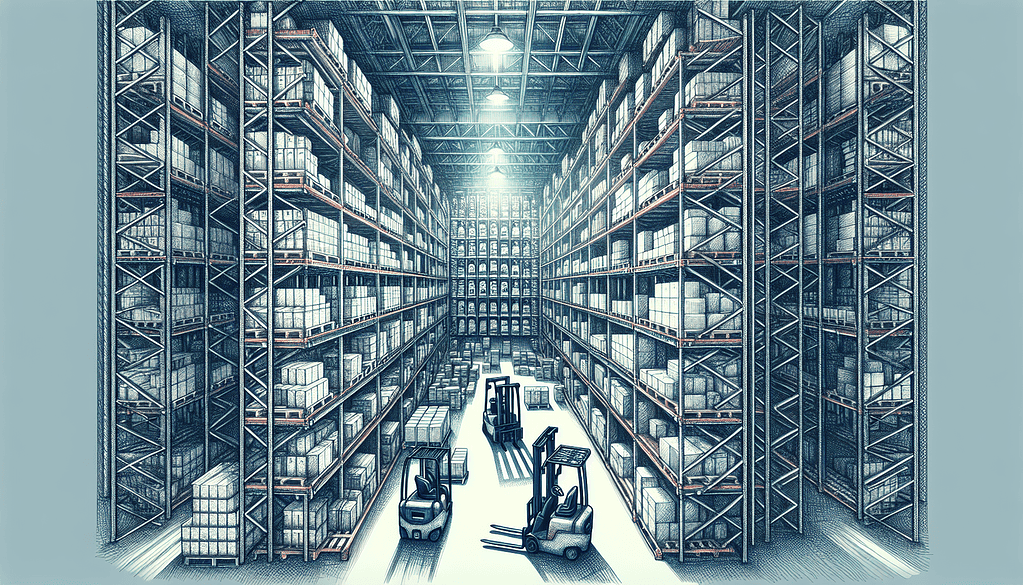

Forklifts and Pallet Jacks: Essential Tools for Warehousing

Undoubtedly, the backbone of any warehouse operation includes forklifts and pallet jacks, essential tools for transporting, hoisting, and orderly stacking substantial loads to maximize space efficiency and utilization within the facility.

While pallet jacks serve as a valuable adjunct to forklifts by providing an easier-to-operate solution for relocating less weighty cargo across smaller expanses, it is crucial to adhere strictly to safety protocols when handling these instruments.

Vigilance in safe usage is key to averting injuries and minimizing potential harm to merchandise during transfer and warehousing.

Choosing the Right Shelving Unit for Your Warehouse

Choosing the perfect heavy duty shelving system for your warehouse needs can be daunting due to the many options available.

It requires a careful evaluation of your requirements and juxtaposing various styles of shelving units.

Factors such as your warehouse’s size constraints, the variety of inventory it accommodates, and financial considerations must all be considered.

Planning an efficient aisle layout in your warehouse is critical.

This will allow machinery like forklifts to operate safely without causing damage to racks through improper navigation.

Assessing Your Storage Needs

If you’re wondering how to assess your requirements accurately, examine your inventory management strategies.

You can liberate valuable space by pinpointing items in your operation that are either obsolete, damaged, or seldom moved and disposing of them accordingly.

Next, consider the nature of the goods you have on hand and scrutinize the utilization of your space.

With a well-planned arrangement within your operation that optimally positions uprights and beams, capacity can be significantly increased, and overall workflow efficiency can improve substantially.

Comparing Different Shelving Styles

After evaluating your requirements, examining various shelving styles to maximize efficiency and inform your choices is essential.

Assess the shelves’ construction, taking into account the materials employed and their distinctive attributes that meet your demands.

Consider environmental considerations such as temperature fluctuations, humidity levels, and possible chemical interactions that can sway your decision on shelving systems.

Also, remember that different shelving styles have diverse maintenance needs. These will influence ongoing expenses and the effort required for their preservation.

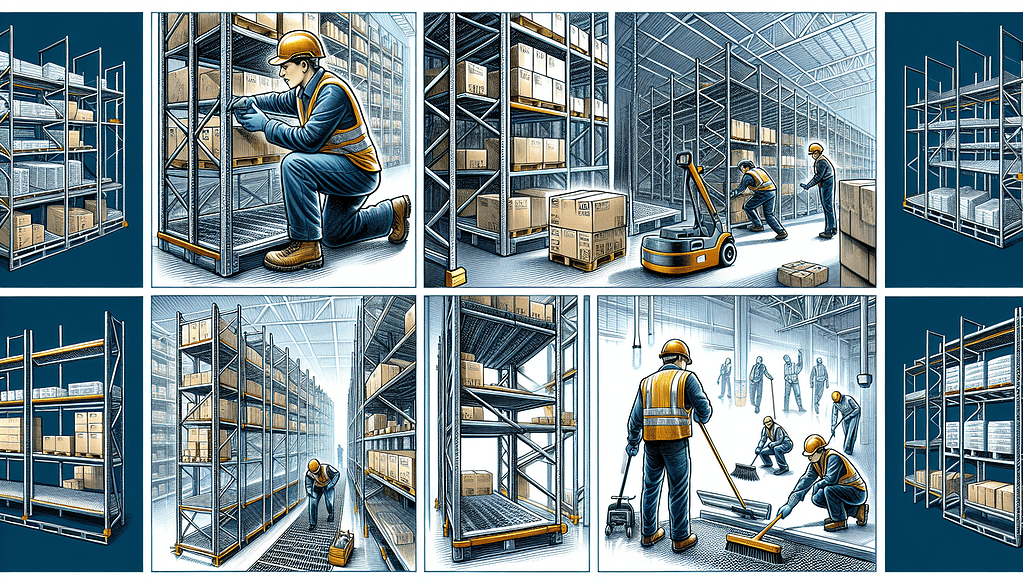

Maintenance and Safety Tips for Warehouse Shelves

The task doesn’t involve choosing the shelving and organizing your warehouse.

It’s imperative to continuously maintain and prioritize safety to avert any harm or injuries that might stem from pallet rack systems within the facilities.

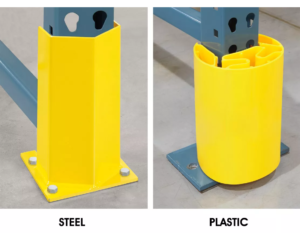

To safeguard against potential equipment-induced damage, it is advisable to equip your racks with security features such as guardrails, rack guards, and column protectors. Those shown here are from Uline.com.

Ensure that your shelving units are mounted at heights deemed safe according to OSHA regulations to reduce risks of shelf collapse or inventory spillage.

Regular Inspections and Cleaning

Maintaining the safety and functionality of the warehouse involves consistent upkeep, which includes routine inspections and cleanliness.

Incorporating these checks into daily activities guarantees sustained maintenance and enhances safety measures, especially within your heavy duty pallet rack.

It’s important not to overlook the necessity of daily visual examinations. Such inspections can reveal early indications of deterioration or damage, as well as yearly expert evaluations that assess the structural soundness of your warehouse.

Proper Loading and Unloading Techniques

Techniques for loading and unloading are essential to uphold safety within the warehouse and adhere to OSHA standards. Securely place your loads on designated support beams instead of using makeshift supports, which helps prevent overburdening shelves and preserves their capacity.

Ensure pallets are correctly positioned when loaded so that weight is distributed uniformly, thus safeguarding the rack system’s structural integrity.

Continuous education in safety protocols for staff members is paramount in sustaining a secure workplace while guaranteeing adherence to OSHA guidelines.

Case Study: Successful Warehouse Storage Solutions in Action

Imagine Aldi’s distribution hub in Bolton, Manchester, as a practical example. In partnership with Warehouse Storage Solutions, Aldi equipped the facility with tailor-made options that adhered to the scheduled timeline and the financial plan for its finalization.

What was achieved? The creation of an expansive 550,000-square-foot warehouse offering extensive capacity for up to 23,556 pallets distributed among different dedicated areas.

This setup showcases a proficient approach to warehouse optimization and streamlines operations—a testament to the collaborative triumph between Aldi and Warehouse Storage Solutions in delivering effective solutions.

Summary – Shelf for Warehouse Storage

Thus, it’s clear that warehouse shelving goes beyond mere storage. It is integral to optimizing rack utilization, boosting efficiency, and ensuring safety. From pallet racking to wire decking or bulk racks, every variety of shelving has a pivotal role in streamlining warehouse activities.

It’s essential to carefully evaluate your specific demands, explore various rack styles, and maintain your systems’ integrity through consistent inspections and correct loading and unloading practices. Cheers to achieving an orderly and efficient warehouse!

Frequently Asked Questions

Q: What is the importance of warehouse shelving and pallet racking?

Shelving in a warehouse is essential for the smooth running of a business. It enables optimal storage use and facilitates efficient storage. Shelving also significantly contributes to enhancing productivity by simplifying the organization and facilitating quick access to goods.

Q: What are the benefits of pallet racking systems?

Pallet racking systems offer sturdy storage solutions that reduce the risk of product damage while optimizing storage. They are a versatile option for diverse infrastructure requirements.

Q: How can I choose the right shelving unit for my warehouse?

When selecting the appropriate storage racks for your warehouse, evaluate your storage requirements and scrutinize the kinds of inventory you have in terms of size and financial constraints. Then, weigh different shelving styles by looking at their construction, materials used, compatibility with your environment, and upkeep needs. Do you need heavy duty shelving units or light?

Q: What are some safety precautions for warehouse shelves?

To maintain the safety of your warehouse shelving, it is essential to employ accessories such as guardrails and column protectors. Shelves should be erected at heights that are compliant with OSHA regulations. Regular inspections and cleaning of these shelving units are crucial.

Make sure to uphold a secure environment in your warehouse without any accidents!

Q: What are some proper loading and unloading techniques for warehouse shelves?

For the smooth functioning of warehouse activities, it is critical to meticulously arrange loads on support beams and evenly distribute weight across pallets. Continuous safety training for staff members must be prioritized.

It cannot be overstated that maintaining safety should be the foremost concern in all warehouse operations.