Warehouse KPIs That Matter in 2026 – A Practical Guide for Managers

Warehousing in 2025 isn’t just about moving pallets—it’s about measuring results. Every KPI for warehouse operations tells you where efficiency is thriving and where you’re losing time, money, or accuracy. Whether you oversee a fulfillment center or a regional DC, tracking the right KPIs ensures your operation runs with precision.

Why KPI for Warehouse Operations Matters

A KPI for warehouse performance is more than a number—it’s a decision-making tool. The right KPIs reveal bottlenecks, highlight cost savings, and help managers balance speed with accuracy. Without them, warehouses risk incurring higher costs, experiencing late orders, and facing customer dissatisfaction.

Core Warehouse KPIs in 2025

Order Picking Accuracy

Target: 99.9%

Errors in picking cause delays and returns. Voice-picking and barcode scanning keep mistakes below 0.1%.

Inventory Accuracy

Target: 97%+

Cycle counting and RFID reduce stock discrepancies and prevent costly overstock or shortages.

Dock-to-Stock Cycle Time

Target: <8 hours

This KPI measures inbound efficiency. The faster goods move to storage, the quicker they can ship.

Order Cycle Time

Target: Same-day or next-day

Measures time from order placement to shipment—critical for e-commerce fulfillment.

Space Utilization

Target: 80–85%

Slotting, mezzanines, and vertical racking optimize square footage and reduce wasted space.

Labor Productivity (Units/Hour)

Target: Industry-specific

Tracks throughput per worker. Automation (AMRs, WES) is key to improvement.

Carrying Cost of Inventory

Target: <25% of inventory value

Storage, depreciation, and insurance add up. JIT and demand forecasting reduce this burden.

Return Rate Due to Fulfillment Error

Target: <1%

Tracks preventable returns caused by picking or shipping errors.

Navigating Inventory KPIs

Accuracy Rate

Aligning physical stock with system records is vital for order fulfillment. Cycle counting ensures accuracy.

Inventory Turnover

High turnover indicates healthy demand and efficient replenishment. Low turnover ties up cash flow.

Carrying Costs

Measure the percentage of inventory value spent on storage, handling, and insurance. High costs often point to overstocking.

Order Fulfillment KPIs

Order Cycle Time

Shorter cycle times = happier customers. Lean processes and WMS integration reduce delays.

Perfect Order Rate

A “perfect order” is on time, accurate, and undamaged. This KPI reflects customer satisfaction.

Backorder Rate

Shows how often demand exceeds available inventory. High backorder rates signal poor planning.

Picking Process KPIs

Picking Accuracy

High picking accuracy reduces returns and increases customer trust.

Picking Productivity

Units picked per labor hour highlight efficiency. AMRs and pick-to-light systems drive improvements.

Space and Resource Utilization KPIs

Space Utilization

Maximizing cubic space ensures better ROI on warehouse real estate.

Labor Cost Analysis

Tracks cost per order for labor. Identifies staffing inefficiencies and opportunities for automation.

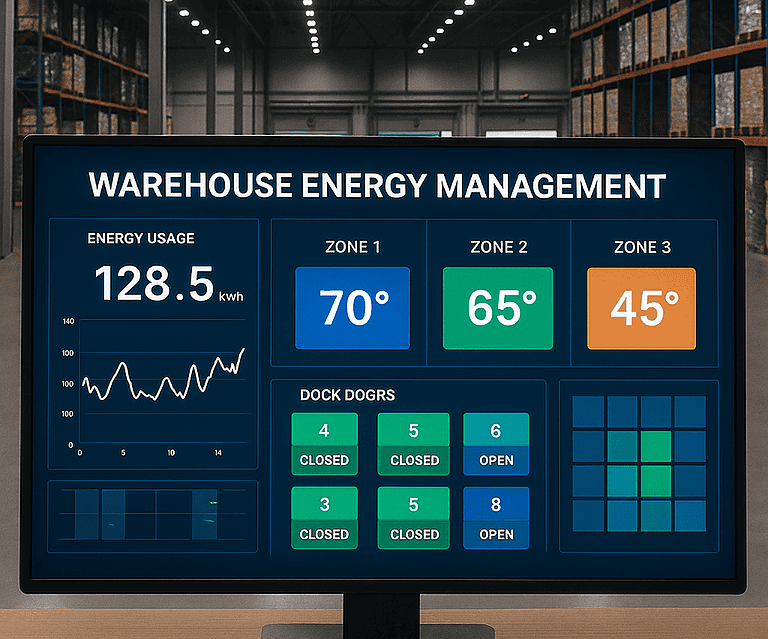

WMS and KPI Dashboards

Modern WMS platforms create real-time KPI for warehouse dashboards, consolidating picking, inventory, and labor data into one view. These dashboards act as a “command center” for continuous improvement.

Safety and Compliance KPIs

Safety Metrics: Monitor near misses, accidents, and compliance audits.

Training Effectiveness: Ensures staff are trained to handle tasks safely and efficiently.

Cost Management KPIs

Transportation Costs: Optimize loads and routes to reduce per-shipment expenses.

Shrinkage: Tracks inventory loss through theft, misplacement, or damage.

Customer-Focused KPIs

On-Time Delivery Rate: A leading indicator of customer satisfaction and loyalty.

Conclusion

The right KPI for warehouse operations serves as a compass, guiding managers toward efficiency, accuracy, and profitability. By focusing on metrics such as order accuracy, space utilization, and cycle time, warehouses in 2025 can enhance performance, lower costs, and deliver a better customer experience.

Additional Resources

FAQ

What is KPI for warehouse operations?

It’s a measurable performance indicator such as inventory accuracy, order cycle time, or labor productivity.

Which warehouse KPI improves customer satisfaction?

A perfect order rate and on-time delivery rates directly impact customer loyalty.

How can I reduce warehouse carrying costs?

Implement JIT, improve forecasting, and eliminate excess stock to reduce carrying costs.

Why is inventory turnover important?

It measures how quickly stock is sold and replenished, impacting cash flow and storage costs.