The 7 Best Goods to Person Systems Revolutionizing 2026

Imagine cutting your warehouse picking time by 65% while doubling accuracy. That’s not science fiction—it’s the power of cutting-edge goods-to-person systems. But with so many options, how do you choose the right one?

In today’s fast-paced e-commerce landscape, warehouse efficiency isn’t just about staying competitive—it’s about survival. Goods-to-person systems have emerged as game-changers, dramatically reducing worker travel time and skyrocketing productivity. These systems enhance reliability, efficiency, and overall performance, directly contributing to increased customer satisfaction. However, with many options flooding the market, decision paralysis is real.

Goods-to-person applications enhance efficiency by delivering items directly to pick stations, increasing accuracy and throughput.

This comprehensive guide examines the top 7 goods-to-person vendors shaping the future of warehouse automation. We’ll cut through the jargon and marketing hype to clearly and unbiasedly compare industry leaders like AutoStore, OPEX Perfect Pick, and Swisslog CarryPick.

Whether you’re a small business looking to scale or a large corporation aiming to optimize operations, we’ve got you covered. We’ll explore each system’s unique features, pros and cons, and ideal use cases. By the end of this post, you’ll have the insights needed to make an informed decision that could revolutionize your warehouse operations.

Ready to unlock unprecedented levels of efficiency and accuracy in your fulfillment process? Let’s dive into the world of goods-to-person systems and find the perfect fit for your business needs.

Top 7 Goods-to-Person Solutions

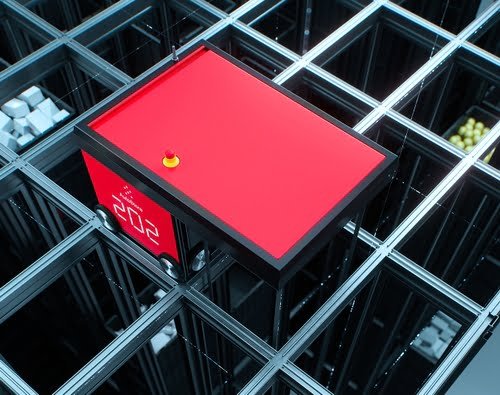

1. AutoStore

AutoStore is a Norwegian company known for its high-density storage and retrieval system.

It uses a grid of bins stacked vertically, with robots moving on top to retrieve and deliver items. This goods-to-person (GTP) system utilizes robots to bring items directly to stationary workers, significantly reducing manual labor and the time spent picking tasks.

Key Features:

Cubic storage design for maximum space

Scalable system that can be easily expanded

Energy-efficient robots with regenerative energy technology

Suitable for various industries and product types

Pros:

Extremely space-efficient, ideal for operations with limited floor space

High reliability with redundant robots

Flexible configuration options

Best for batch-picking orders with high quantities

Cons:

Initial setup costs can be high

May require significant changes to the existing warehouse layout

Low-velocity products can limit overall throughput capacity

Best For: Companies with limited space looking for high-density storage solutions.

AutoStore Video

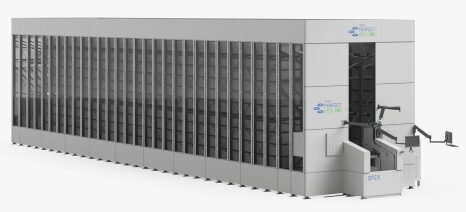

2. OPEX Perfect Pick

OPEX Corporation’s Perfect Pick is an aisle-based goods-to-person technology using iBOTs (intelligent robots) for item retrieval. Selecting the right goods-to-person solution based on specific organizational needs is crucial, as these systems can significantly increase productivity, improve accuracy, and optimize space.

Key Features:

iBOTs can travel both vertically and horizontally within aisles

Direct-to-pick delivery without transfers between subsystems

Scalable design allows for easy expansion

Energy-efficient operation with iBOTs sharing power

Pros:

High-speed picking capabilities

Reduced maintenance due to fewer moving parts

Can handle various tote and item sizes

Some operations utilize picking robots parasitically

Cons:

Limited flexibility in aisle configuration once installed

May not be as space-efficient as some cube storage systems (typical storage space utilization is 50%)

Systemic interface could require months of coding

Best For: Warehouses requiring high-speed picking and straightforward scaling options.

OPEX Perfect Pick Video

3. Swisslog CarryPick

Swisslog’s CarryPick system uses autonomous mobile robots (AMRs) to transport entire shelving units to picking stations. Goods-to-person technologies, like CarryPick, enhance efficiency in warehouse operations by improving productivity, reducing errors, optimizing space, and providing ergonomic advantages by eliminating unnecessary movement for workers.

Key Features:

Flexible layout that can be easily reconfigured

Robots can operate in existing warehouse structures

Integrated with Swisslog’s SynQ software for warehouse management

Suitable for both small and large operations

Pros:

Highly adaptable to changing business needs

Can be implemented with minimal disruption to existing operations

Scalable from manual to fully automated picking

Cons:

May require more floor space compared to high-density systems

Robot traffic management can be complex in large-scale operations

Best For: Businesses seeking flexibility and easy scalability in their warehouse automation.

Swisslog CarryPick Video

Vanderlande ADAPTO

ADAPTO is Vanderlande’s shuttle-based storage and retrieval system, using autonomous vehicles for goods transport. These systems significantly lower the need for manual labor, leading to cost savings in employee wages and benefits.

Key Features:

3D storage grid with vehicles that can move in all directions

Modular design for easy expansion and reconfiguration

Energy-efficient operation with vehicle energy sharing

Integrated with Vanderlande’s VISION software suite

Pros:

Highly adaptable to different warehouse layouts

Excellent redundancy with multiple vehicles

Can handle a wide variety of product sizes and types

Cons:

Complex systems may require specialized maintenance

Higher initial investment compared to some other options

Best For: Large operations requiring a highly flexible and scalable automated storage solution.

Vanderlande ADAPTO Video

Dematic Multishuttle

Dematic’s Multishuttle system uses rail-guided shuttles for high-density storage and retrieval of totes or cartons. These systems streamline the workflow for order picking, reduce human error, and enhance overall productivity in the order fulfillment process.

Key Features:

Multiple shuttles can operate in each aisle for high throughput

Suitable for both ambient and cold storage environments

Integrated with Dematic’s software for optimized performance

Can be combined with other automated systems for end-to-end solutions

Pros:

High storage density and fast retrieval times

Flexible enough to handle various load types

Good option for multi-deep storage

Cons:

Fixed rail system limits flexibility compared to some AMR solutions

It may require significant initial infrastructure changes

Best For: Warehouses needing high-density storage with rapid retrieval capabilities.

Dematic Multishuttle 2 Video

Knapp OSR Shuttle

Knapp’s OSR (Order, Storage, Retrieval) Shuttle system is a flexible storage solution known for its high performance. In contrast to goods-to-person systems like the OSR Shuttle, person-to-goods systems involve human workers traveling through aisles to manually select items.

This method can impact productivity, costs, and efficiency, making it crucial for organizations to consider which automation strategy to implement.

Key Features:

Shuttle vehicles serve multiple levels within storage aisles

Can handle a wide range of tote and carton sizes

Integrated with Knapp’s KiSoft software suite

Suitable for various industries, including pharma and fashion

Pros:

High throughput capabilities

Energy-efficient design with lightweight shuttles

Can be easily expanded or reconfigured

Cons:

May require a significant upfront investment

Complex systems may need specialized maintenance and support

Best For: Operations requiring high-speed, high-volume order fulfillment with diverse product ranges.

KNAPP AG OSR Shuttle Video

SSI Schaefer Cuby

The Cuby shuttle system from SSI Schaefer is designed for efficient small parts handling and storage. Additionally, integrating ‘pick to light’ technology into these systems significantly improves order accuracy and efficiency in warehouse operations by directing workers to the exact location of items using visual cues.

Key Features:

Single-level shuttles for each storage level

Modular design allows for easy system expansion

Can be integrated with other automated systems

Suitable for various container types and sizes

Pros:

High storage density for small to medium-sized items

Scalable solution that can grow with business needs

Energy-efficient operation

Cons:

May not be as suitable for larger or irregularly shaped items

Fixed infrastructure can limit flexibility for major layout changes

Best For: Businesses handling small to medium-sized products requiring high-density storage and quick retrieval.

Cuby Video

How to Choose the Right Goods to Person System

Selecting the ideal goods-to-person system for your warehouse depends on several factors:

- Space Constraints:

- High-density systems like AutoStore or Dematic Multishuttle are ideal for limited space.

- More flexible systems like Swisslog CarryPick might be better if you have ample floor space.

- Scalability Needs:

- Consider future growth. Systems like OPEX Perfect Pick and SSI Schaefer Cuby offer easier expansion options.

- Product Characteristics:

- Size, weight, and variety of your inventory will influence your choice.

- Knapp OSR Shuttle and Vanderlande ADAPTO handle a wide range of product types.

- Throughput Requirements:

- High-volume operations might benefit from systems like Dematic Multishuttle or Knapp OSR Shuttle.

- Budget Considerations:

- Initial investment vs. long-term ROI

- Consider the total cost of ownership, including maintenance and energy costs

- Integration Capabilities:

- Ensure the system can integrate with your existing WMS and other warehouse technologies.

- Flexibility:

- If your business experiences frequent changes, consider more adaptable systems like Swisslog CarryPick or Vanderlande ADAPTO.

Comparison Table

Here’s a quick reference table comparing key aspects of each system:

| System | Storage Density | Scalability | Flexibility | Speed | Best For |

|---|---|---|---|---|---|

| AutoStore | Very High | High | Moderate | High | Space-constrained operations |

| OPEX Perfect Pick | High | High | Moderate | Very High | High-speed picking |

| Swisslog CarryPick | Moderate | Very High | Very High | High | Adaptable operations |

| Vanderlande ADAPTO | High | High | High | High | Large, diverse inventories |

| Dematic Multishuttle | High | High | Moderate | Very High | High-volume operations |

| Knapp OSR Shuttle | High | High | High | Very High | Diverse product ranges |

| SSI Schaefer Cuby | Very High | High | Moderate | High | Small-parts handling |

Conclusion

The goods-to-person market is rapidly evolving, with each system offering unique advantages. AutoStore excels in space utilization, while Swisslog CarryPick offers unparalleled flexibility.

OPEX Perfect Pick and Dematic Multishuttle shine in high-speed operations, while Vanderlande ADAPTO and Knapp OSR Shuttle offer excellent versatility for diverse product ranges. SSI Schaefer Cuby provides an efficient solution for small parts handling.

Your choice should align with your specific operational needs, future growth plans, and budget constraints. Before deciding, consider arranging demonstrations or site visits to see these systems.

Remember, the most advanced system isn’t always the best fit. The ideal solution integrates seamlessly with your existing processes, addresses your current challenges, and positions your warehouse for future success. Additionally, these systems optimize warehouse space by utilizing robotic-based Goods-to-Person (GTP) automation to maximize vertical space and improve efficiency.

Frequently Asked Questions (FAQs)

Q: How does a goods-to-person system work?

GTP systems use technologies like robots, conveyors, or automated storage and retrieval systems (AS/RS) to transport items to picking stations. Workers then pick items from the delivered containers and place them into shipping cartons.

Q: What are the benefits of using a goods-to-person system?

GTP systems offer numerous benefits, including increased picking accuracy, improved order fulfillment speed, reduced labor costs, optimized space utilization, and enhanced worker ergonomics.

Q: How much does a goods-to-person system cost?

The cost of a GTP system varies significantly based on the size of the warehouse, the chosen technology, and the complexity of the implementation. It’s essential to get quotes from multiple vendors and consider the total cost of ownership, including installation, maintenance, and software costs.

Q: What factors should I consider when choosing a goods-to-person system?

Several factors influence the choice of a GTP system, including warehouse size, product mix, order volume, budget, and desired level of automation. It’s crucial to assess your needs and consult experts to find the best fit.

Q: Can goods-to-person systems be integrated with warehouse management systems (WMS)?

Yes, most modern GTP systems can integrate with existing WMS software to streamline operations and provide real-time inventory and order status data.

Q: How long does it take to implement a goods-to-person system?

The implementation timeline depends on the system’s complexity and the warehouse’s size. It can range from several weeks to several months.

Q: What is the impact on existing warehouse operations during implementation?

Implementing a GTP system may require some disruptions to warehouse operations. However, many vendors offer phased implementation plans to minimize downtime and ensure a smooth transition.