Reverse Logistics Management: Saving Profit Margin in 2026

Picture this: A customer returns a barely used blender. Instead of gathering dust in a warehouse, it’s quickly refurbished and resold at a profit. That’s the magic of reverse logistics management—revolutionizing how smart businesses operate.

The definition of reverse logistics involves returning products from consumers, recycling, repurposing, and refurbishing. It plays a crucial role in the supply chain by emphasizing reverse logistics’s growing importance and market dynamics.

Hey there, supply chain enthusiasts and business owners! Let’s talk about the unsung hero of modern commerce: reverse logistics.

You know that sinking feeling when you see a mountain of returns piling up? Or the headache of figuring out what to do with all those obsolete gadgets? Buckle up because we’re about to turn that frown upside down.

Reverse inventory management isn’t just a fancy term to impress your boss at the next meeting. It’s a game-changer that can beef up your bottom line, make Mother Nature smile, and have your customers singing your praises from the rooftops.

In this no-nonsense guide, we’ll explore reverse logistics, why it matters, how to nail it, and what the future holds. Whether you are a seasoned pro or a curious newbie, you’ll walk away with actionable insights to supercharge your operations.

So grab a coffee, get comfy, and let’s unpack the secrets of reverse logistics processes. Trust me, by the end of this post, you’ll be itching to revamp your supply chain and wondering how you ever lived without it.

Ready to flip the script on returns and reclaim some serious cash? Let’s dive in!

The Concept of Reverse Logistics

Alright, let’s break it down. Reverse logistics is like the cooler, more complex cousin of traditional logistics. While regular logistics is about getting products from A to B, reverse logistics handles everything that goes backward in the supply chain.

So, what is reverse logistics? It is the process that involves the return of products from customers back to the seller or manufacturer.

This is crucial in supply chain management, especially with the increasing pressures from e-commerce and consumer expectations.

Think about it:

Customer returns? That’s reverse logistics.

Repairing and refurbishing products? Yep, reverse logistics.

Recycling old electronics? You guessed it – reverse logistics.

So, what is reverse logistics in the supply chain? It is the process that facilitates the return of products from customers to sellers or manufacturers, managing returns and associated activities like repairs and recycling.

The reverse logistics process is not just about slapping a return label on a box and calling it a day. It’s a whole ecosystem of processes that deal with products after the point of sale.

It’s about squeezing every last drop of value from your inventory, even when things don’t go according to plan.

Why Reverse Logistics Process Matters

Now, I know what you’re thinking. “Sure, it sounds nice, but is it worth the hassle?” Buckle up because the benefits of nailing an efficient reverse logistics process will blow your mind.

Cha-Ching! Cost Savings and Revenue Generation: Remember that blender from earlier? Instead of writing it off as a loss, proper reverse logistics turns it into cold, hard cash. Refurbishing and reselling returned items means you’re not just cutting losses but opening up new revenue streams. Ka-ching!

Mother Nature’s High Five: Environmental Benefits Let’s face it: we’ve only got one planet. Reverse logistics helps you do your part by reducing waste and promoting recycling. It’s not just good karma; it’s good business. Consumers love eco-friendly brands, and you’ll love the positive PR.

Happy Customers, Happy Life: Boosting Satisfaction and Loyalty Nobody likes a complicated return process. By streamlining your reverse logistics, you tell customers, “We’ve got your back.” Easy returns and exchanges mean happy customers and happy customers mean repeat business. It’s a win-win!

Stay Out of Trouble: Regulatory Compliance Depending on your industry, proper product disposal might not just be nice—it might be the law. Solid management keeps you on the right side of regulations, avoiding fines and legal headaches.

Waste Not, Want Not: Inventory Optimization By getting a handle on returns and repairs, you’ll have a clearer picture of your inventory needs. This means less dead stock gathering dust and more efficient use of your warehouse space. Your accountant will thank you. Effective inventory management can significantly reduce costs and improve profitability.

Data, Data, Data: Valuable Insights Every return, repair, and recycle is a goldmine of data. Proper management allows you to spot trends, improve product quality, and make smarter business decisions. It’s like having a crystal ball but way more practical.

The Bottom Line: Reverse logistics management isn’t just a cost center – it’s a secret weapon for boosting profits, delighting customers, and staying ahead of the competition. Ignore it at your peril!

Next, we’ll examine the nitty-gritty of key processes. Get ready to roll up your sleeves and get into the good stuff!

Reverse Logistics Processes: The Nuts and Bolts

Let’s get dirty and break down the core processes that make reverse logistics tick. It’s not rocket science, but it requires serious planning and coordination.

The Return of the Product: Handling Those Comebacks

First things first: make it easy for customers to initiate returns. Clear policies and user-friendly interfaces are your friends here.

A quick tip: Use QR codes or smart labels to speed up the process and reduce errors.

Inspect and Decide: Playing Product Detective

Once a product’s back in your hands, it’s time to play detective. What’s the condition? Can it be resold as-is, or does it need some TLC?

Pro move: Train your staff to be expert assessors. The quicker and more accurately they can categorize returns, the smoother your reverse logistics operations will run.

Repair and Refurbish: Giving Products a Second Chance

This is where the magic happens for items that need a bit of love. Fixing, cleaning, and sprucing up products can turn potential losses into profitable sales.

Remember: Sometimes, selling for parts is more cost-effective. Know when to fix and when to flip!

Repackage and Resale: Back to the Shelf

Once a product’s good as new (or good enough), it’s time to get it back out there. This might mean returning it to regular stock or selling it through alternate channels.

Insider tip: Consider creating a “refurbished” section on your website. Many customers love a good deal on like-new items.

Recycle and Dispose: When It’s Time to Say Goodbye

Responsible disposal is key for products that can’t be saved. This isn’t just about being green (though that’s important)—it’s also about compliance and reputation.

Don’t forget: Many materials can be recycled for a small profit. Every little bit counts!

To stay competitive, companies must optimize supply chain logistics to handle returns efficiently and sustainably.

Supply Chain Challenges

Now, I won’t sugarcoat it – reverse logistics can be tricky. Here are some common hurdles you might face:

The Crystal Ball Problem: Forecasting Headaches

Unlike regular sales, returns can be unpredictable. One viral TikTok about a product flaw, suddenly, you’re swamped!

Tip: Use data analytics to spot trends and prepare for seasonal spikes.

Quality Control Quandaries: Is It Broken?

Sometimes, returned products work just fine. Other times, they’re beyond saving. Sorting this out quickly and accurately is crucial.

Solution: Implement standardized testing procedures and consider investing in diagnostic tools.

The Money Pit: Managing Costs

Reverse logistics can be expensive. Effective packaging management can help reduce these costs by reusing and recycling materials.

Strategy: Look for ways to optimize each step. Can you consolidate shipments? Automate any processes? Effective management of packaging materials is also crucial to align with environmental sustainability efforts.

Tech Troubles: System Integration Woes

Your reverse logistics system must integrate with your existing inventory and sales platforms, which isn’t always easy.

Advice: When choosing software, prioritize solutions that offer robust integration capabilities.

The Need for Speed: Time Sensitivity

In many cases, the quicker you process returns, the more value you can reclaim. But speed can’t come at the cost of accuracy.

Balancing act: Use performance metrics to find the spot between speed and precision.

Best Practices

Now that we’ve covered the challenges let’s talk about solutions. Here are some best practices to keep your reverse logistics running like a well-oiled machine:

- Strategy Is King: Have a Plan

- Don’t wing it. Develop a comprehensive reverse logistics strategy that aligns with your overall business goals.

- Key point: Your strategy should be flexible enough to adapt to changing market conditions.

- Embrace the Robots: Automation Is Your Friend

- From sorting returned items to processing refunds, automation can speed things up and reduce errors.

- Cool tech alert: Some warehouses are using AI-powered robots to handle returns. The future is now!

- Data, Data, Data: Leverage Analytics

- Use data to forecast return volumes, identify problem products, and optimize your processes.

- Pro tip: Consider implementing predictive analytics to stay one step ahead.

- Team Up: Collaborate with Partners

- Your suppliers, carriers, and customers can be valuable allies in improving your reverse logistics.

- Idea: Set up a feedback loop with your product development team to reduce returns at the source.

- Keep Learning: Continuous Improvement

- The world of reverse logistics is always evolving. Stay curious, keep learning, and be ready to adapt.

- Suggestion: Attend industry conferences or join professional groups to stay current with the latest trends.

Whew! We’ve covered a lot of ground here. Our next section will explore how technology revolutionizes reverse logistics management. Get ready for some mind-blowing innovations!

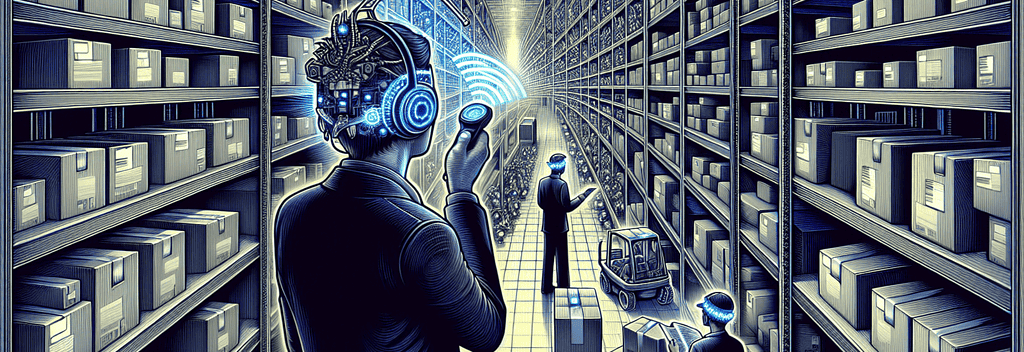

Technology

Buckle up, tech enthusiasts! This is where things get interesting. The right tech can turn your reverse logistics from a necessary evil into a lean, mean, profit-generating machine. Let’s explore some game-changing innovations:

- AI and Machine Learning: The Smart Cookie of Logistics

- Predictive analytics can forecast return rates with scary accuracy.

- AI can sort and route returns faster than you can say “refund.”

- Real-world example: Amazon uses AI to determine whether a return is necessary. Sometimes, they’ll refund you and tell you to keep the item. Mind. Blown.

- Internet of Things (IoT): Everything’s Connected

- Smart sensors can track product conditions in real-time.

- IoT devices in warehouses optimize storage and retrieval.

- Cool application: Some companies use IoT to detect when a product might fail, triggering proactive maintenance before a return is needed.

- Blockchain: Trust but Verify

- Ensures transparency and traceability throughout the reverse logistics process.

- It helps combat fraud and counterfeit returns.

- Fun fact: Some luxury brands use blockchain to authenticate returned items, saving millions in fraudulent returns.

- Robotic Process Automation (RPA): The Tireless Worker

- Automates repetitive tasks like data entry and basic decision-making.

- Reduces errors and speeds up processing times.

- Neat trick: Some RPA bots can even handle customer service inquiries about returns, freeing your human staff for more complex issues.

- Augmented Reality (AR): See the Unseen

- Helps warehouse staff locate and sort items more efficiently.

- Can guide technicians through repair processes.

- Futuristic feature: Imagine customers using AR to see how a refurbished product looks before buying. The future is now!

- 3D Printing: Print, Don’t Ship

- Can produce replacement parts on-demand, reducing inventory costs.

- Speeds up repair processes.

- Mind-bender: Some companies are exploring 3D printing for packaging customized to each return. Talk about reducing waste!

Let’s get real: reverse logistics isn’t a one-size-fits-all game. Different industries face unique challenges. Let’s break it down:

- E-commerce: The Return-a-palooza

- Challenge: High return rates, especially in apparel.

- Solution: Virtual try-ons using AR, detailed product descriptions, and customer reviews to reduce returns.

- Pro tip: Offer in-store returns for online purchases to reduce shipping costs and increase foot traffic.

- Electronics and Technology: The Complexity Conundrum

- Challenge: Rapid obsolescence and complex repairs.

- Solution: Modular design for easier repairs and robust recycling programs.

- Insider info: Some tech giants are exploring “device as a service” models to manage product lifecycle better.

- Automotive: Heavy Metal Returns

- Challenge: Large, heavy items with high shipping costs.

- Solution: Regional repair and refurbishment centers to minimize transportation.

- Industry trend: The focus on remanufacturing is increasing to extend the life of vehicle components.

- Fashion and Apparel: The Fit Dilemma

- Challenge: High return rates due to sizing issues.

- Solution: Advanced sizing technologies, like body scanning apps.

- Creative idea: Some brands are experimenting with “fitting room” subscription boxes to reduce overall returns.

- Pharmaceuticals: Handle with Extra Care

- Challenge: Strict regulations and potential health hazards.

- Solution: Specialized handling procedures and secure destruction processes.

- Critical point: Temperature-controlled reverse logistics is crucial for many medications.

Measuring Success

Alright, data nerds (I say that with love), this section’s for you. How do you know if your reverse logistics strategy is working? Let’s talk metrics:

- Return Rate: The Big One

- What it is: Percentage of sold items that are returned.

- Why it matters: High return rates can indicate product quality issues or unclear descriptions.

- Pro tip: Break this down by product category to identify problem areas.

- Cost per Return: Show Me the Money

- What it is: The average cost to process a return.

- Why it matters: It helps you understand the true impact of returns on your bottom line.

- Insider trick: Include hidden costs like customer service time and lost sales opportunities.

- Time to Refund: Speed Matters

- What it is: Average time from return initiation to refund processed.

- Why it matters: Faster refunds = happier customers.

- Quick win: Automate parts of the refund process to speed things up.

- Recovery Rate: Turning Lemons into Lemonade

- What it is: Percentage of returned item’s value you can recoup.

- Why it matters: Higher recovery rates mean less money lost on returns.

- Strategy: Optimize your refurbishment and resale processes to boost this number.

- Customer Satisfaction: The Holy Grail

- What it is: How happy customers are with your return process.

- Why it matters: Happy customers come back (and bring friends).

- Measurement tip: Use surveys and monitor social media sentiment.

Remember, the key is to track these metrics over time and look for ways to improve. A 1% improvement might not seem like much, but it can translate to big bucks in reverse logistics.

Future Trends in Reverse Logistics Management

Alright, future gazers, let’s dive into what’s coming down the pike. Spoiler alert: it’s pretty exciting stuff.

Circular Economy Integration: Full Circle, Baby

We’re moving beyond the “take-make-dispose” model to a more sustainable “make-use-return-reuse” approach.

Expect to see more companies designing products with their eventual return and reuse in mind.

Prediction: By 2030, circular economy principles will be standard in most industries.

Hyper-Personalization: The Return Experience of One

AI and big data will enable ultra-tailored return experiences.

Imagine systems that predict when a customer will likely return an item and proactively reach out with solutions.

Cool concept: “Smart returns” that automatically adjust refund amounts based on product condition and customer history.

Drone and Autonomous Vehicle Returns: Look Up in the Sky!

As regulations evolve, expect drones to handle small returns in urban areas.

Self-driving vehicles could revolutionize the transportation aspect.

A far-out idea: How about a self-driving mobile return center that comes to the customer?

Green Reverse Logistics: Earth First

Sustainability will become a primary driver, not just a nice-to-have.

Biodegradable packaging, zero-waste policies, and carbon-neutral shipping will become the norm.

Trend to watch: Some companies are exploring “return offsets” – planting trees or funding green initiatives to balance the environmental impact of returns.

Predictive Quality Control: Stop Problems Before They Start

Advanced analytics will help identify potential quality issues before products leave the warehouse.

This proactive approach could significantly reduce return rates.

Cutting-edge tech: Imagine AI systems that can predict product failures based on usage data and automatically trigger preventive measures.

Conclusion: The Future is Now

Whew! What a ride. We’ve journeyed through the ins and outs of returns management, from the basics to the bleeding edge. Let’s recap the key takeaways:

Reverse logistics isn’t just about handling returns – it’s a goldmine of opportunity for cost savings, customer loyalty, and new revenue streams.

Technology is revolutionizing the field, with AI, IoT, and blockchain leading the charge.

Different industries face unique challenges, which can become competitive advantages with the right strategies.

Measuring your performance is crucial. Remember: what gets measured gets managed.

The future types of reverse logistics operation is green, circular, and hyper-personalized.

Here’s the bottom line: In today’s competitive business landscape, effective returns management isn’t just nice – it’s a must-have.

It’s the difference between seeing returns as a cost center and viewing them as an opportunity for growth and customer loyalty.

So, what’s your next move? Whether you’re just starting to think about these logistics or looking to up your game, the time to act is now.

Start small if you need to – maybe by implementing better tracking or exploring automation options. The important thing is to get the reverse logistics process rolling.

Remember, every great strategy starts with a single step. So take that step. Your bottom line, customers, and even Mother Earth (waste management) will thank you.

Now, over to you. What reverse supply chain management aspect are you most excited to explore or improve in your business? The future is bright, and yours is to shape.