5G Warehouse Automation: How Next-Gen Connectivity Transforms Operations

Warehouses are under constant pressure to move faster, operate smarter, and adapt to customer expectations. While robotics, AI, and IoT are already reshaping the industry, the arrival of 5G connectivity is unlocking the full potential of warehouse automation.

5G warehouse automation isn’t just about speed—it’s about low latency, reliability, and massive device connectivity that allow real-time coordination between people, robots, and systems.

What Is 5G Warehouse Automation?

5G warehouse automation is the integration of fifth-generation mobile networks into warehouse operations to improve:

Speed: Data transfer rates up to 100x faster than 4G.

Latency: Ultra-low delays (<1 ms) for real-time decision-making.

Capacity: Support for thousands of IoT devices per warehouse.

This connectivity enables the automation of processes that previously struggled with Wi-Fi dead zones or network congestion.

Benefits of 5G in Warehousing

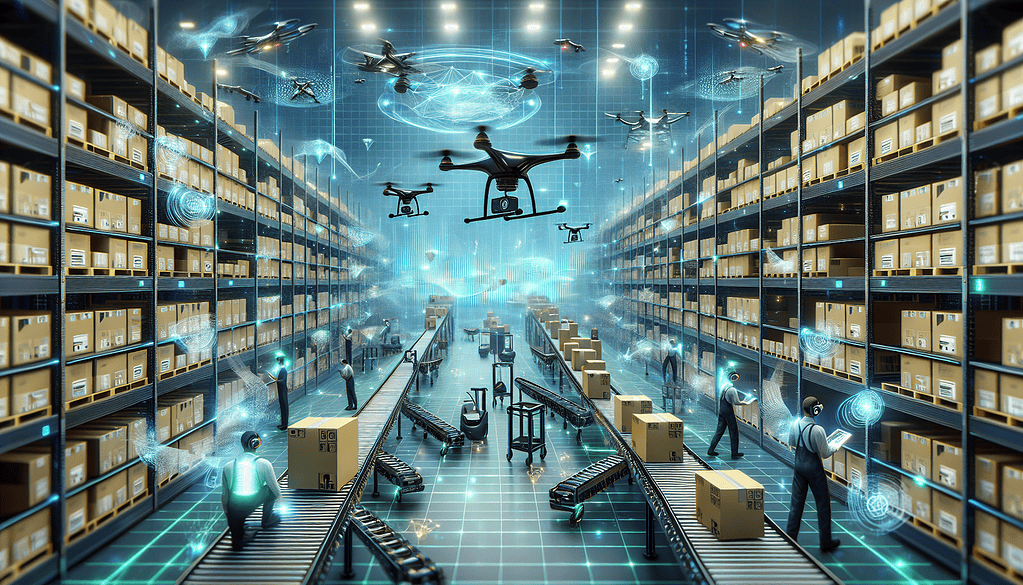

1. Real-Time Robotics & Autonomous Vehicles

AGVs and AMRs (Automated Guided Vehicles & Autonomous Mobile Robots) can navigate with continuous communication to cloud-based controls.

Reduced risk of collisions due to instant response times.

Scalability: entire fleets of robots can be deployed simultaneously.

2. Smarter Inventory Management with IoT

5G enables thousands of connected sensors to track pallets, bins, and packages in real time.

Integration with RFID and barcode scanners becomes seamless.

Predictive analytics, powered by continuous data streams, can forecast shortages before they occur.

3. Enhanced Worker Safety

Wearable devices connected via 5G can monitor fatigue, PPE compliance, or hazardous exposure.

Drones equipped with 5G video streaming can inspect racks, mezzanines, or hard-to-reach areas without delay.

4. Seamless Cloud Integration

Traditional Wi-Fi struggles with interference, coverage gaps, and bandwidth limits.

With 5G, WMS (Warehouse Management Systems) and WES (Warehouse Execution Systems) can operate in the cloud, enabling instant communication with devices and robots.

Scalable infrastructure reduces the need for on-site servers.

5. Future-Proofing Against Market Demands

As e-commerce continues to grow, warehouses must be able to handle surges without downtime.

5G provides the flexibility to add more connected devices without replacing infrastructure.

Opens the door for digital twins, AI-powered slotting, and fully autonomous warehouses.

👉 According to a recent McKinsey report on the future of connectivity, 5G’s ultra-low latency and high device capacity will play a critical role in scaling warehouse automation and IoT adoption.

Challenges of 5G Warehouse Automation

While promising, adoption isn’t without obstacles:

Cost of infrastructure: Private 5G networks require investment in antennas, servers, and integration.

Skill gaps: Workers and IT teams need training to manage 5G-enabled environments.

Cybersecurity: More devices = greater attack surface. Security protocols must be enhanced.

Compatibility: Legacy warehouse systems may need upgrades to fully benefit.

Use Cases Already Emerging

Amazon & DHL are piloting 5G networks to manage robot fleets and predictive maintenance.

Smart ports and logistics hubs utilize 5G to connect cranes, trucks, and warehouses into a single ecosystem.

Smaller warehouses are adopting 5G-powered drones for cycle counting

For example, DHL partnered with Ericsson in a 5G smart warehouse trial that showed how connected robotics and real-time data flows can significantly boost efficiency and reduce downtime.

The Future of 5G in Warehousing

Looking ahead, 5G will support:

Dark warehouses: Fully automated sites running with little or no human labor.

AI-powered digital twins for real-time simulations.

Seamless integration with blockchain and supply chain visibility platforms.

Warehouses that adopt early will gain a competitive advantage in terms of speed, accuracy, and cost efficiency.

Conclusion

5G warehouse automation isn’t a buzzword—it’s the backbone of the next generation of logistics. By enabling real-time robotics, smarter inventory tracking, safer work environments, and seamless cloud integration, 5G is revolutionizing the way warehouses operate.

Companies that start exploring private 5G networks today will be positioned to lead tomorrow’s supply chains.