Robot-as-a-Service (RaaS) in Warehousing: Benefits and Use Cases

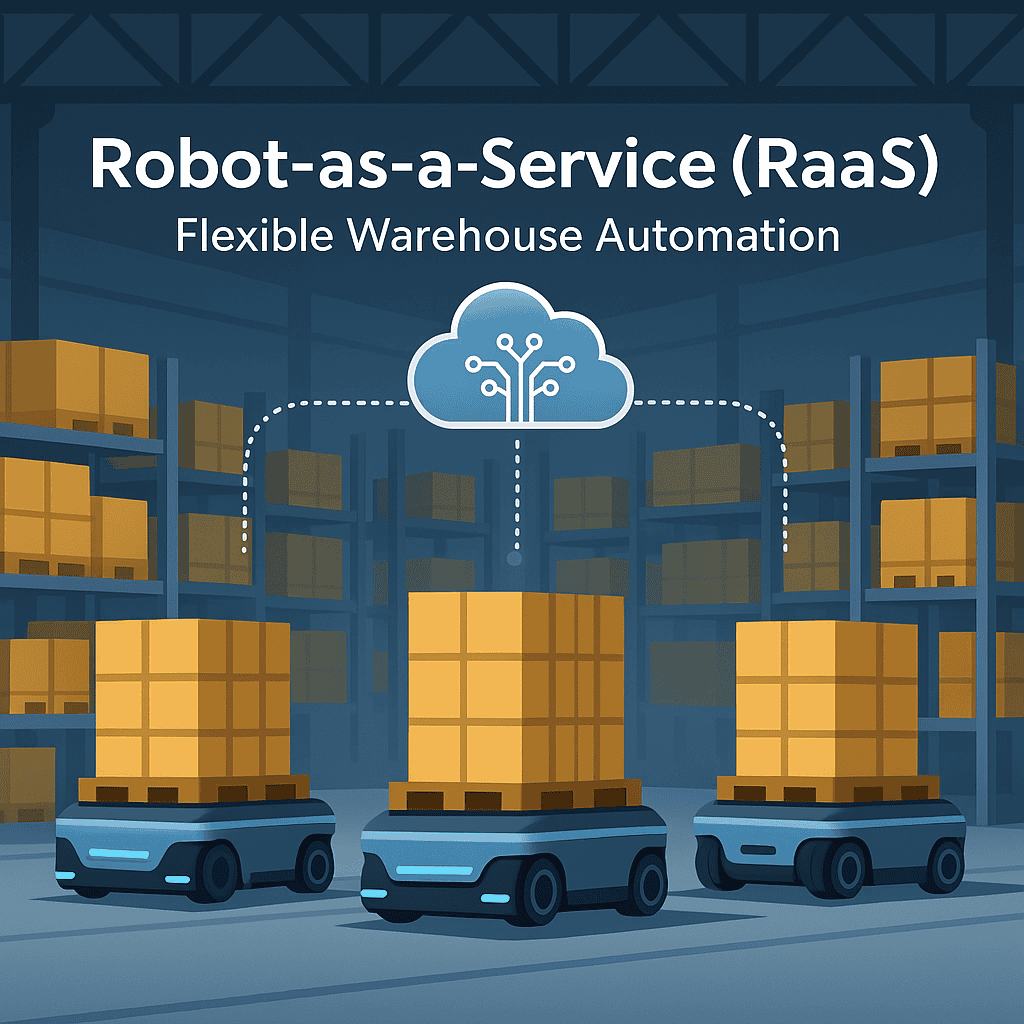

Automation is no longer limited to large enterprises with deep budgets. Robot-as-a-Service (RaaS) is reshaping how warehouses deploy automation by providing robots through a subscription model — much like SaaS software. Instead of owning and maintaining expensive robotic systems, businesses can pay monthly fees and scale robot fleets up or down as needed.

This flexibility makes RaaS one of the fastest-growing trends in warehouse automation.

Key Takeaways

Robot-as-a-Service (RaaS) offers robotics via a subscription model, reducing upfront costs.

Warehouses can scale automation quickly to handle seasonal peaks or business growth.

Benefits include cost savings, reduced risk, and access to the latest technology.

Common use cases include picking, sorting, pallet transport, and mobile robotics.

What Is Robot-as-a-Service?

RaaS is a business model where robotics providers rent or lease robots instead of selling them outright. Warehouses benefit from:

No heavy upfront capital investments

Maintenance and support included in the service

Access to upgrades as technology advances

Scalability — add more robots during peak season and scale down afterward

Think of it as outsourcing your automation needs while maintaining full control of operations.

Benefits of RaaS in Warehousing

Lower Financial Risk

With subscription pricing, companies avoid millions in upfront investments. Costs shift to operational expenses (OPEX) instead of capital expenditures.

Scalability and Flexibility

Need more robots during the holidays? Add them for a few months. Once demand cools, scale down without long-term contracts.

Access to Innovation

RaaS providers continuously update fleets with new models, AI, and sensors — giving your warehouse access to cutting-edge tech without reinvestment.

Faster Deployment

Robots can be delivered, set up, and integrated within weeks, compared to traditional automation projects that take years.

Warehouse Use Cases for RaaS

Autonomous Mobile Robots (AMRs): Handle picking routes, material transport, and zone-to-zone moves.

Automated Pallet Movers: A Replacement for Forklifts in Repetitive Pallet Transport.

Collaborative Robots (Cobots): Assist workers with tasks such as packing, sorting, and palletizing.

Automated Sortation: Subscription-based conveyor robots and sortation systems for e-commerce fulfillment.

These solutions eliminate bottlenecks and enhance throughput without requiring permanent automation infrastructure.

Choosing the Right RaaS Provider

When evaluating RaaS providers, consider:

Integration capabilities with your WMS/WES

Service-level agreements (SLAs) for uptime and maintenance

Pricing model flexibility (per robot, per pick, per hour)

Scalability for seasonal or long-term growth

Training and support for warehouse teams

The right provider should function as a long-term partner, not just a vendor.

Challenges of RaaS

Dependence on provider: Service interruptions may halt automation.

Integration complexity: Not all legacy WMS platforms support plug-and-play robotics.

Hidden costs: Be aware of fees associated with usage, maintenance, or software licenses.

Careful contract review ensures predictable ROI.

The Future of Robot-as-a-Service

RaaS is poised to transform small- and mid-sized warehouses by lowering barriers to automation. As robotics becomes smarter and more affordable, RaaS will shift from an optional experiment to a standard business model for fulfillment centers.

FAQs

What is Robot-as-a-Service (RaaS)?

RaaS is a subscription model that enables warehouses to lease robots rather than purchasing them outright.

How does RaaS reduce costs?

It eliminates high upfront capital expenses, shifts costs to OPEX, and includes maintenance and upgrades.

What warehouse tasks are best suited for RaaS?

Picking, pallet movement, order sortation, and cobot-assisted packaging are common applications.

Is RaaS only for large companies?

No. Smaller warehouses benefit most since they gain access to robotics without major investment.