Warehouse SKU Slotting: Tips & Tricks for a Successful 2026

Imagine your warehouse as a beehive. Busy worker bees (pickers) constantly buzz around fulfilling orders, but are they bogged down searching for the right products? Warehouse SKU slotting is the secret to a streamlined hive, placing high-demand items within easy reach and optimizing your entire picking process.

Introduction to SKU Slotting

Is your warehouse a well-oiled machine, or a chaotic scramble to find the right products? Inefficient SKU slotting can cripple your picking times, accuracy, and overall warehouse efficiency. But fear not, logistics superheroes!

This blog dives deep into the world of SKU slotting, your key to unlocking a faster, smoother, and more profitable warehouse operation.

We’ll explore what slotting is, why it matters, and the factors to consider for optimal placement. We’ll also unveil best practices, helpful technology, and some common pitfalls to avoid.

So, buckle up, warehouse managers and logistics professionals, and get ready to transform your warehouse into a hive of peak productivity!

What is Warehouse SKU Slotting?

Have you ever played a game of Tetris? Now, imagine doing that with your entire warehouse inventory! Warehouse SKU slotting is essentially the strategic placement of each item (SKU – Stock Keeping Unit) within your facility.

It’s like assigning each player on your warehouse basketball team the perfect position to maximize their strengths and minimize wasted movement.

By strategically slotting your SKUs, you determine the designated location for every item, from the high-flying fast-sellers to the rarely-needed benchwarmers. This directly impacts your core warehouse processes:

- Picking: Efficient slotting puts frequently picked items closest to pickers, minimizing travel time and maximizing order fulfillment speed.

- Put-away: Knowing the designated spot for each incoming SKU streamlines the receiving process and reduces time spent searching for storage space.

- Replenishment: A well-slotted warehouse ensures easy access to high-demand items for frequent restocking, keeping your picking operation running smoothly.

Factors to Consider for Effective Slotting

The key to unlocking efficient slotting lies in understanding your warehouse and its inventory. Here are some crucial factors to consider when making strategic placement decisions:

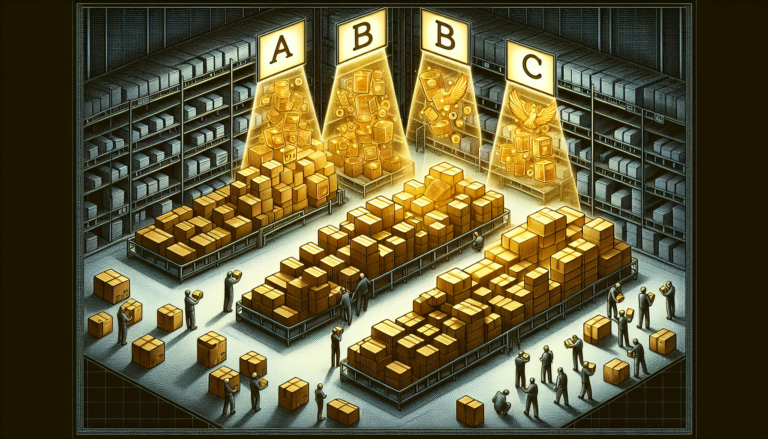

SKU Data Analysis

- Data is king! Before you start rearranging shelves, analyze your SKU data like a pro. This includes historical demand patterns, pick frequency, weight, and dimensions of each item.

- ABC analysis is your secret weapon. It classifies SKUs based on demand (A – high demand, B – medium demand, C – low demand). This helps prioritize storage locations, placing your “A-listers” (fast movers) front and center for easy access.

Warehouse Layout and Storage Systems

- Think flow, not maze! Consider your warehouse layout and picking methods. Are you using zone picking, batch picking, or something else? This will influence where you place frequently picked items.

- Not all shelves are created equal. Different storage systems, such as pallet racks, shelves, and bins, are suited for various weights, sizes, and accessibility needs. Heavy machinery might find a happy home on sturdy pallet racks, while smaller, frequently picked items might thrive on easily accessible shelves.

Additional Considerations

Even with a solid data analysis and warehouse layout plan, there are a few other factors to keep in mind for truly effective slotting:

- Safety First! Regulations often dictate storage locations for hazardous materials. Flammable liquids won’t be hanging out next to the office coffee maker!

- Seasonality Matters. Do you experience predictable spikes in demand for certain items throughout the year? Plan accordingly by allocating temporary storage space for seasonal hot sellers.

- Compatibility Counts. Not all products play well together. Consider co-location strategies. For example, you might keep frequently purchased complementary items close to each other to streamline picking for bundled orders.

Conclusion

By now, you’ve unlocked the secrets of warehouse SKU slotting! Remember, an effective slotting plan is the cornerstone of a smooth-running, efficient warehouse operation. Here’s a quick recap of the benefits:

- Faster Picking Times: Strategic placement minimizes picker travel time, leading to quicker order fulfillment and increased productivity.

- Improved Order Accuracy: Reduced picking errors ensure your customers receive the right items every time.

- Optimized Space Utilization: Every inch of your warehouse is put to good use, maximizing storage capacity.

- Enhanced Worker Safety: Proper slotting considers safety regulations, keeping your warehouse a hazard-free zone.

- Reduced Costs: Streamlined processes translate to lower labor costs and improved efficiency.

Ready to transform your warehouse into a hive of productivity? Implement these slotting best practices, leverage technology, and watch your warehouse operations soar! Don’t hesitate to consult with warehouse management experts for further guidance on optimizing your slotting strategy.