The 3 Best Warehouse Racking Providers: New and Used 2026

The right racking system can mean the difference between chaos and efficiency in warehousing. But with countless providers vying for your attention, how do you separate the players from the pretenders? This blog will review the 3 best warehouse racking providers for new and used racking.

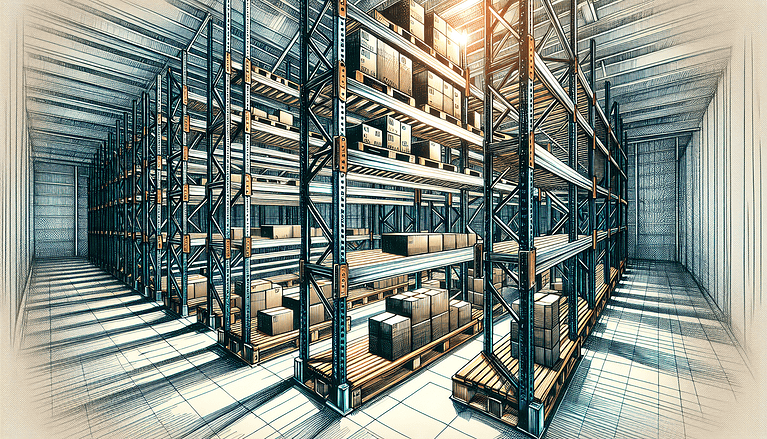

Warehouse racking systems are the backbone of any warehouse operation, turning vertical space into a treasure trove of organized inventory. In our previous post, we discussed pallet racking as the key to maximizing warehouse efficiency, improving product access, and tailoring solutions to inventory needs. But the quality of your racking system is only as good as the supplier you choose.

In today’s market, it’s a tough call. Are you in the market for new systems with all the latest features or want to stretch your budget with quality-used options? Whatever you choose will impact your operation for years to come.

Here’s the list of top providers for new and used warehouse racking. We’ll look at what makes them tick and what they offer and give you the facts to decide. From global giants to specialist suppliers, we’ve got you covered. Let’s get started and find your perfect racking supplier.

New Warehouse Racking Providers

These are the ones to beat when equipping your warehouse with the latest racking technology. Each offers a mix of innovation, quality, and service that could change your storage game.

Warehouse rack systems are crucial in optimizing warehouse space, offering various styles and configurations to meet specific storage needs.

1. Interlake Mecalux

Interlake Mecalux has been in the material handling industry for over 50 years. With a global presence and a reputation for being at the cutting edge, they are the go-to name for warehouses of all sizes.

Products and services:

Selective pallet racking

Drive-in and drive-through racking

Pallet flow systems

Automated storage and retrieval systems (AS/RS)

Custom-designed solutions

Interlake Mecalux is known for integrating robotics and automation into its racking systems. Their Easy WMS warehouse management software is a highlight, as well as real-time inventory control and optimization.

2. SSI Schaefer

Founded in 1937, SSI Schaefer started as a small workshop in Germany and is now a global logistics and warehousing solutions company. Its commitment to innovation and sustainability has kept it at the top of its game.

Products and services:

Static and mobile racking systems

Mezzanines and multi-tier installations

Automated small parts warehouses

Conveyor systems

Warehouse management software

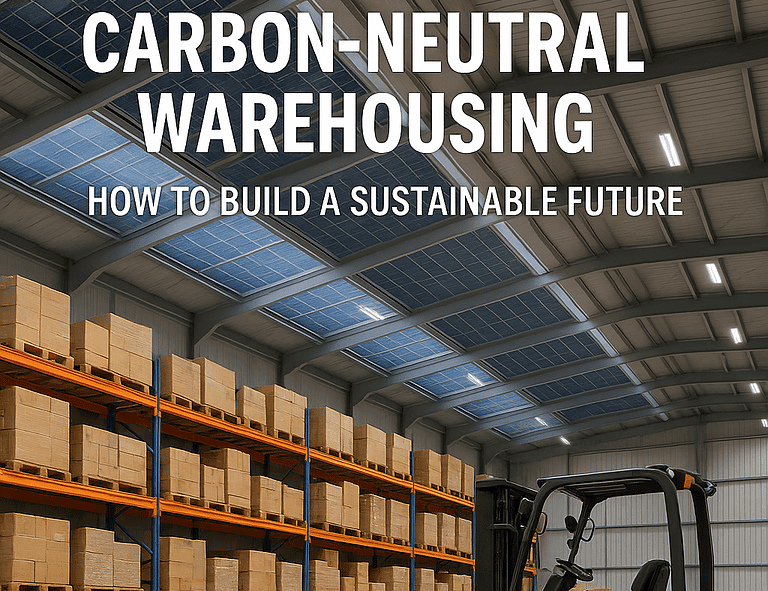

SSI Schaefer’s modular design means highly customizable solutions that can grow with your business. It focuses on energy-efficient systems, and using recycled materials in production sets them apart regarding sustainability.

When designing these customizable solutions, it is crucial to consider the pallets’ dimensions and the pallet load’s total height to ensure optimal storage efficiency.

3. Unarco Material Handling

One of the oldest pallet rack manufacturers in the USA, Unarco has been providing storage solutions since 1955. Their American-made products are known for being tough and reliable.

Products and services:

Selective pallet rack

Drive-in and drive-through rack

Push back rack

Cantilever rack

Carton flow systems

Notable features or innovations: Unarco’s patented Seismic Base Isolator technology is a must have for warehouses in earthquake prone areas, it reduces the risk of collapse during seismic events. Their in-house engineering team also offer custom design services for tricky storage problems.

Each of these suppliers brings something different to the table, from Interlake Mecalux’s automation to SSI Schaefer’s sustainability and Unarco’s seismic safety. When looking for a new racking system get in touch with these companies to see how their solutions fit your needs.

Used Warehouse Racking Suppliers

Using warehouse racking is a great option to get the most for your budget without quality. These top-used racking suppliers have a range to suit all needs and budgets.

Warehouse storage is crucial for optimizing space within a warehouse, so choosing the right racking systems is essential.

1. Used Pallet Rack Suppliers

Used Pallet Rack Suppliers have been established as a leading supplier of used racking systems. Their customer service and large inventory have made them a one-stop shop for businesses all over the country.

Types of used racking

Selective pallet rack

Drive-in and drive-through systems

Push back rack

Carton flow rack

Teardrop style racking

Pallet rack suppliers, established as leading suppliers of used racking systems. Their customer service and large inventory have made them a one-stop shop for businesses nationwide. Additionally, they offer a variety of pallet rack accessories, which are essential for enhancing the functionality and density of pallet storage systems.

2. SJF Material Handling

With over 40 years in business, SJF Material Handling has established itself as a provider of quality used equipment. They have a large inventory and can source hard-to-find items.

Types of used racking

Pallet rack systems

Cantilever rack

Mezzanines

Conveyor systems

Wire partitions and security cages

SJF offers a combination of used, new, and refurbished equipment so customers can mix and match according to their needs and budget. Their in-house refurbishment process ensures used equipment meets high quality and safety standards.

3. Global Equipment Company

Global Equipment Company, or Global Industrial, is a large distributor of industrial and business equipment, i.e., inventory of used warehouse rac distributor king.

Types of used racking

Pallet racks

Rivet shelving

Wire shelving

Bulk storage racks

Steel shelving

Global Equipment Company’s size allows it to offer competitive pricing and many options. It also has new equipment, so it can be a one-stop shop for warehouses to combine new and used solutions.

What to Consider When Choosing a Racking Supplier

Choosing a used racking supplier can save you a lot of money without sacrificing quality. They inspect and refurbish their inventory so the equipment meets safety standards and works well. Selecting the right pallet rack system for your warehouse is crucial to ensuring efficiency and safety.

Whether you choose new or used racking, here are the key factors to consider:

Product quality: Ensure the supplier meets industry standards and has good products.

Range of products: Look for suppliers with various racking types to suit your needs.

Customer service and after-sales support: Good suppliers have installation assistance, maintenance support, and responsive customer service.

Price and value: Get quotes from different suppliers, but remember that the cheapest isn’t always the best value in the long run.

Industry reputation and customer reviews: Check the supplier’s background and what other customers say about them.

By considering these and researching thoroughly, you can find a racking supplier that meets the warehouse’s quality, service, and value requirements.

New vs. Used Racking

When choosing between new and used racking, it’s important to know the pros and cons of each. This will help you decide what’s best for your warehouse. Additionally, selecting the right rack system based on your warehouse’s needs is crucial for optimal organization and safety.

New racking benefits

Latest materials and design.

They are manufactured and provide a warehouse layout.

Full warranties and manufacturer support.

Complies with industry standards and regulations.

It can last longer and be better value in the long run.

Warehouse shelving plays a crucial role in storing products efficiently and contributes to the functionality and structural integrity of the racking systems.

Used racking benefits

It’s much cheaper than new systems.

Available for quick delivery and installation, so you don’t have to wait.

It helps with sustainability by reducing waste and the demand for new materials.

Being tested in a warehouse has been the environment.

A good option for temporary storage or businesses with changing needs.

When to choose new racking:

Your warehouse needs the latest safety features or technology

You’re planning for long-term growth and want a system that can grow

Industry regulations are critical

When to use used racking:

Budget is the main issue

It would be best if you got in the warehouse quickly

Your storage needs are temporary or will change soon

You’re expanding an existing system and need matching components

Ultimately, it’s all about your situation, budget, timeline, long-term plans, and type of inventory. Some businesses choose a combination of new and used racking to balance cost savings with specific needs for certain warehouse areas.

Remember, whatever you choose, new or used racking, it’s important to ensure all equipment is safety-compliant and installed and maintained properly.

Conclusion

The best racking solution isn’t always the newest or the cheapest but offers the right balance of quality, fit, and value for your warehouse. When deciding, consider product quality, customer support, price, and industry reputation.

Whether new or used, your chosen racking system should improve your warehouse’s efficiency, maximize space, and contribute to a safer working environment. It’s an investment in your business’s future, and choosing the right supplier is the first step to optimizing your storage.

Call to Action

Let us know about your experience with warehouse-racking suppliers. Have you worked with any of the companies mentioned in this article? Or maybe you found another supplier that exceeded your expectations? Comment below to help other warehouse managers make a decision.

Are you unsure which racking solution is best for your warehouse? Our team can help. We can evaluate your needs and connect you with suppliers who match them. Contact us for a personalized consultation, and let’s find the right racking solution for your business.

Remember, the right racking system can transform your warehouse operations. Research, ask questions, and choose a supplier that matches your goals. Your future self (and your warehouse team) will thank you!