Warehouse Picking Accuracy: 5 Advanced Strategy Ideas

In the fast-paced world of logistics, warehouse picking accuracy isn’t just about hitting numbers — it’s a reflection of culture, discipline, and pride. A 98.5% accuracy rate may look impressive on paper, but in practice, it can result in hundreds of mis shipments per week, frustrated customers, and rising costs.

Imagine a warehouse where every order flows seamlessly from shelf to shipment, where errors are rare and morale is high. That’s not a dream — it’s a choice. And this post will show you how to make that choice, using five advanced strategies that transform accuracy from a metric into a mindset.

Pro Tip: Early in my career, I ran a facility stuck at 98.5% accuracy. We aimed for 99.8%, but the team didn’t see the urgency — until I asked:

“Would a 98.5% success rate be acceptable in a hospital delivery room?”

That hit home.

We introduced real-time feedback loops, friendly accountability, and posted daily error rates. Within six weeks, accuracy climbed to 99.2%.

The lesson: people perform best when they understand the stakes and own the results.

1. Master Internal vs. External Quality Metrics

Internal Quality

These are in-house audits that reveal how well your process performs before the customer sees the product.

Common audit types include:

Random Audits: Pull orders randomly between picking and packing.

System-Driven Audits: Let your WMS automatically divert high-risk orders for QA.

Size/Weight-Based Audits: Compare live dimensions and weights to system data.

Image-Based Audits: Utilize cameras to verify the appearance of SKUs.

Load Audits: 100% pallet-level checks for retail shipments.

External Quality

External Quality reflects the customer’s view — how often you ship the right item, in the right quantity, on time, and undamaged.

Typical errors include:

Wrong or missing item in carton

Incorrect quantity (2 vs. 3)

Wrong case or SKU shipped

Tip: Separate missing cartons/cases (tracked under Cargo Loss) from picking accuracy.

2. Audit to Mirror the Customer Experience

To align Internal Quality with customer outcomes, your audits must represent all picking types:

Full pallet and bulk picks

Full-case and case-pack picks

Unit or each-picks

If external errors outnumber internal finds, increase your sample size or re-examine audit coverage. Audit inbound receipts, putaway, replenishment, and dock-to-stock flows — they all feed picking accuracy.

3. Calculate Accuracy the Right Way

Facility-Level Internal Quality

Case Accuracy: Correct cases ÷ Total cases picked

Unit Accuracy: Correct units ÷ Total units picked

Track daily, post results by noon, and review immediately — feedback decays by the hour.

External Quality (Perfect Order)

Formula: Accurate Orders ÷ Total Orders Shipped

Each order counts as one — regardless of the number of mistakes.

Exclude missing shipments (they belong to Cargo Loss).

The “Perfect Order” combines:

Fill Rate (no backorders)

On-Time Delivery

Order Accuracy

Example:External Quality = (0.4 × Fill Rate) + (0.3 × On-Time Delivery) + (0.3 × Order Accuracy)

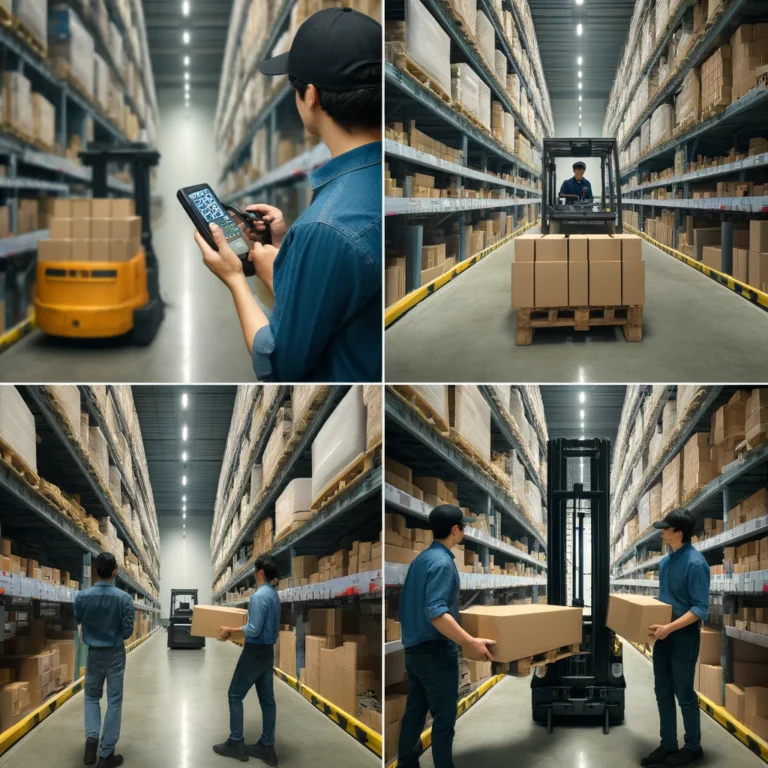

4. Build Accountability Through Visibility

Real-Time Feedback

Provide immediate feedback when a mis-pick occurs. It helps identify upstream issues (such as mis-stocked SKUs) and keeps pickers engaged in the correction process.

Post Results Publicly

Display previous-day accuracy results in picking zones. Even anonymized (using IDs), this encourages healthy competition and awareness.

Don’t judge on raw error counts — always measure errors as a percentage of total picks.

Case Picking Discipline

When a picker mis-picks a full case, have them correct and re-pick it themselves. This hands-on learning builds ownership and reinforces accurate habits.

5. Leverage Technology and Data to Drive Precision

Today’s accuracy leaders combine process rigor with digital intelligence:

WMS-Driven Audits: Auto-divert exceptions using predictive rules.

Pick-to-Light / Voice Systems: Guide associates visually or verbally, reducing cognitive load.

Computer Vision: Detect incorrect SKU, label, or orientation before packing.

IoT Sensors: Track case movement to detect misplaced or dropped cartons.

Real-Time Analytics: Dashboards showing accuracy by zone, picker, and SKU velocity.

Accuracy isn’t luck — it’s the product of systems that see, alert, and learn.

Conclusion: Warehouse Picking Accuracy

Perfect orders aren’t the result of luck or software — they’re the byproduct of clarity, ownership, and systems that make excellence repeatable.

By mastering internal and external metrics, auditing smartly, and blending technology with accountability, you’re not just shipping orders — you’re shipping confidence.

In warehousing, precision isn’t a KPI — it’s a culture. And those who build it will define the next decade of logistics excellence.

FAQs

Q1: What is a good warehouse picking accuracy rate?

Most high-performing operations target 99.8% or better. Anything below 99% signals process or training issues.

Q2: What causes most picking errors?

Top causes include mis-stocked SKUs, wrong quantities, poor lighting or labeling, and distractions during picking.

Q3: How can technology improve accuracy?

WMS audits, pick-to-light, voice systems, and computer vision reduce human error and validate picks automatically.

Q4: Should I track accuracy by person or team?

Both. Track individual accuracy for accountability, but review team averages to identify systemic or training issues.

Q5: How often should audits be done?

Daily mini-audits and weekly deep audits strike the right balance between insight and efficiency.