Best Warehouse Drones for Warehousing Success 2026

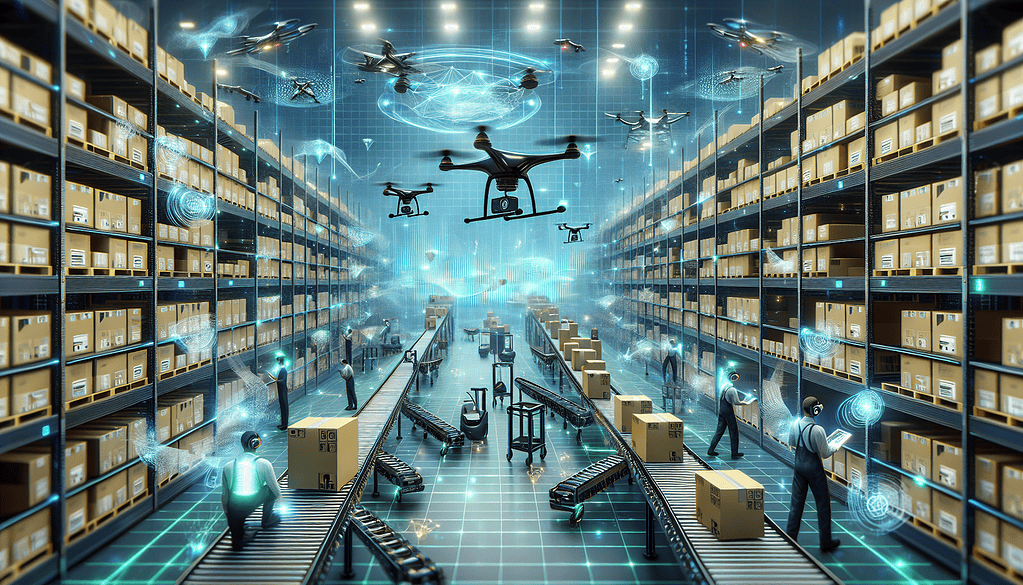

Are you ready to improve your cycle counting process? Warehouse drones will revolutionize inventory management and skyrocket efficiency.

These high-tech helpers transform how businesses track stock, optimize space, and streamline operations. From lightning-fast cycle counts to real-time inventory updates, warehouse drones are setting new industry standards.

In the fast-evolving warehousing world, staying ahead means embracing technology that enhances accuracy and speeds up operations.

Once a novelty, warehouse drones have become essential tools in modern warehouses, providing innovative solutions to age-old logistical challenges.

From real-time inventory tracking to ensuring security and optimizing layout, the best drones for warehouse management in 2024 offer unparalleled advantages.

This blog explores how these flying assistants are not just futuristic gadgets but crucial components of a successful warehousing strategy.

Best Warehouse Drones

Vimaan StorTRACK AIR

This is by far my favorite. Of all the drones I’ve test-driven, this one performs the best. If you can handle the price, you won’t be sorry.

Infinium Scan

These can avoid obstacles and people, and provide real-time analytics on inventory without needing to be in the warehouse.

DJI Mavic 3 Enterprise

This is a high-end commercial drone designed for tasks like mapping, inspection, and locating lost inventory.

EXO X7 Ranger Plus

This is a great starter drone and is budget-friendly. I would recommend starting with this model unless you have the budget for a nice one.

Editor’s Pick: Vimaan StorTRACK AIR

The Vimaan StorTRACK AIR is an innovative drone solution for inventory management in warehouse environments, representing a leap in aerial robotics platforms.

Unlike traditional drones, the StorTRACK AIR specializes in scanning barcodes and other label information across the entire warehouse space, from floor to ceiling.

This advanced technology enables the StorTRACK AIR to navigate indoors without relying on GPS, using visual data collection for warehouse inventory management and remote sensing operations within the warehouse management system.

Through its advanced optical character recognition capabilities, the inventory drones can create detailed 3D digital models of the warehouse space, including barcode data, and integrate other vital label details.

Pros: Fully autonomous, fast, and accurate inventory audits; creates 3D models and integrates with WMS.

Cons: Limited availability, may require specific warehouse infrastructure for navigation.

Retail: $3,800

One of the standout features of the StorTRACK AIR is its integration with AI-powered analytics, which enhances its ability to track inventory by locating empty bins and providing detailed data on inventory levels.

This integration automates the collection of visual and environmental data, such as product temperature, humidity, and inventory images, to assess perishable product deterioration, enhance warehouse inspections, and improve intralogistics operations.

The system is designed to operate efficiently in warehouse settings, utilizing its robust collision and obstacle avoidance capabilities, which are essential for safe indoor operations.

Additionally, the StorTRACK AIR can operate autonomously, making it an excellent tool for night-time operations when warehouse floors are typically less crowded. By reducing the interaction between drones and human workers, the StorTRACK AIR optimizes workflow and improves safety.

Overall, the StorTRACK AIR by Vimaan represents a significant step forward in warehouse automation, offering a safer and more efficient alternative to manual inventory tracking methods and traditional drone solutions.

Its ability to integrate seamlessly with existing warehouse management systems (WMS) and provide real-time, actionable data makes it a valuable asset for modern logistics and supply chain operations.

Infinium Scan

The Infinium Scan by Infinium Robotics is an advanced autonomous drone system for warehouse inventory management and stock-taking within warehouse environments. It’s automated inventory management at its best!

This system significantly enhances operational efficiency by enabling fully automated stocktaking, which can be conducted during night or off-peak hours to optimize operations further.

Additionally, the Infinium Scan can efficiently manage and scan a warehouse’s entire inventory, collecting comprehensive data on product conditions and facilitating intralogistics with its pre-established flight paths.

Its ability to integrate with 99.9% of Warehouse Management Systems (WMS) makes it highly adaptable and efficient.

Pros: Fully autonomous, highly accurate inventory scanning system that integrates with warehouse management systems.

Cons: Limited availability, may require specific warehouse infrastructure for navigation.

Infinium Scan utilizes artificial intelligence and computer vision technologies to navigate autonomously, avoiding obstacles and requiring no human intervention.

This technology ensures high safety standards, allowing drones to operate safely even in narrow aisles and GPS-denied environments.

The system can accurately count individual boxes or cartons, even if placed at challenging angles or densely packed, and it can scan up to 16,000 full pallet locations per day.

Moreover, Infinium Scan contributes to enhanced safety by reducing the need for workers to perform high-altitude tasks and by delivering accurate, real-time analytics on inventory, which helps make more informed management decisions.

The system’s high-speed operation cuts down the time required for inventory tasks and significantly lowers labor costs, making it a cost-effective solution for modern warehouses.

You can visit their official website for further details on the Infinium Scan.

DJI Mavic 3 Enterprise

The DJI Mavic 3 Enterprise is a highly versatile commercial drone designed to enhance efficiency in various industrial applications such as mapping, surveying, and inspection.

It features a 4/3″ CMOS 20MP wide camera with a mechanical shutter, which minimizes motion blur and is excellent for capturing detailed images swiftly.

It also has a 1/2″ CMOS 12MP telezoom camera capable of 7-56x zoom, allowing for detailed inspections from a distance.

Pros: Excellent camera with zoom and thermal imaging options, centimeter-level precision for mapping, compact and portable.

Cons: Expensive, requires FAA registration, not fully autonomous.

Retail: $3,800

One of the standout features of the Mavic 3 Enterprise is its long flight time, approximately 45 minutes, which facilitates extensive surveys and inspections without the need for frequent landings or battery changes.

This drone supports centimeter-level positioning accuracy thanks to its optional RTK module, making it suitable for precise data collection necessary in professional settings.

The drone’s O3 Enterprise camera system ensures stable and clear video feedback up to 15 km in optimal conditions, which is crucial for maintaining control and situational awareness during flights.

The drone’s design also emphasizes ease of deployment and portability, allowing for rapid setup and operation in various field conditions.

For operations that require recording and repeating specific flight paths, such as routine inspections or surveys, the Mavic 3 Enterprise offers features like Live Mission Recording and Corridor Mission Planning.

These functionalities enable automated flight planning and execution, reducing pilot workload and increasing operational consistency.

Overall, the DJI Mavic 3 Enterprise blends advanced imaging capabilities, extended flight times, and robust software support to meet the demands of modern aerial surveying and inspection tasks. It’s one of the best warehouse drones on the market.

Best Budget Option: EXO X7 Ranger Plus

The EXO X7 Ranger Plus offers versatile, high-performance warehouse drones designed for enthusiasts and more experienced users. It features a 4K photo capability and 2K video resolution at 30 frames per second, supported by a 3-axis gimbal for stable footage.

The drone is equipped with a 1/3.2-inch CMOS sensor and offers a digital zoom, although it’s worth noting that image quality may degrade with increased zoom.

Pros: Long battery life, good camera performance, high hover accuracy, US-made with free pilot training course.

Cons: Heavy, requires FAA registration.

Retail: $459

One of the standout features of the X7 Ranger Plus is its obstacle avoidance system, which is particularly useful for novice pilots.

The system has a range of about 20 meters and helps prevent collisions by stopping the drone when an obstacle is detected, although it does not navigate around obstacles.

Additionally, the drone boasts impressive flight stability, can handle winds up to 25 MPH, and offers a maximum speed of 27 MPH.

In terms of battery performance, the X7 Ranger Plus provides up to 25 minutes of flight time per battery, which is competitive within its price range.

It also features user-friendly controls and several intelligent flight modes, including GPS-assisted automatic return-to-home, waypoint mode, follow-me mode, and orbit mode, enhancing the safety and fun of flying.

Overall, the EXO X7 Ranger Plus is a solid choice for those looking for warehouse drones that combine ease of use with advanced features. It offers good value for money in the mid-range drone market.

Key Features to Look for in Warehouse Drones

Now that we’ve explored some of the top contenders in the warehouse drone market, let’s delve into the key features you should consider when choosing a drone for your operation:

The deployment of multiple drones enables fully autonomous indoor navigation and scanning of inventory items, enhancing efficiency by allowing drones to work together in a fleet for comprehensive inventory management.

Additionally, the use of uncrewed aerial vehicles in smart warehouses for inventory underscores their capability for autonomous flight and task execution, marking a significant advancement in the automation of operations.

Automation Level

Autonomy Spectrum: Warehouse drones come in a range of automation levels. Some require a pilot for operation, while others can fly pre-programmed routes or even navigate autonomously using obstacle avoidance and path-planning software.

Matching Your Needs: Consider the level of human oversight you require. A semi-autonomous drone may be sufficient for tasks that require human decision-making, such as picking and placing specific items. A fully autonomous drone might be ideal for simpler tasks, such as inventory scanning in designated areas.

Battery Life and Flight Time

Warehouse Size and Tasks: The size and layout of your warehouse will determine the flight time needed for permission. Larger warehouses or drones performing extensive inventory scans will require longer flight times.

Impact on Operations: Prioritize drones with long battery life to minimize downtime for charging and ensure uninterrupted operations. Consider hot-swappable batteries for continuous operation.

Payload Capacity

Item Weight and Size: Warehouse drones have varying payload capacities. If you plan to move or manipulate items, ensure the drone can handle their weight and size.

Future Needs: When selecting a payload capacity, consider potential future needs to ensure a suitable fit. For example, you might choose a drone with a higher capacity to accommodate potential growth in product types.

Warehouse Management System (WMS) Integration

- Streamlined Operations: Seamless integration with your existing warehouse management system allows the drone to receive tasks, update inventory data, and generate reports directly within your workflow.

- Reduced Errors: Integration minimizes manual data entry and reduces the risk of errors.

Safety Features

- Obstacle Avoidance: Prioritize drones with robust obstacle avoidance sensors, such as LiDAR or cameras, to prevent collisions with walls, shelves, or workers. Considering the risks and potential consequences of drone crashes is crucial when evaluating the safety features of warehouse drones. These crashes can have a significant impact on people and infrastructure, including the potential for drones to fall onto hard surfaces or shelves. This highlights the safety concerns and potential hazards associated with drone operations in warehouse environments.

- Emergency Landing: Look for features like automatic return-to-home or safe landing protocols in case of signal loss or battery depletion. This feature should also be part of your warehouse management system.

Implementation Tips

Integrating drones into your warehouse operation requires careful planning and preparation. Here are some key steps:

Conduct a needs assessment to identify the specific tasks that drones can address most effectively in your warehouse. Consider factors like warehouse size, layout, and existing workflows.

Develop a deployment plan: This plan should outline how to introduce drones, including training staff, establishing flight zones, and integrating them into your WMS.

Invest in infrastructure (optional): Some drone systems may require specific infrastructure for navigation, such as pre-programmed beacons or Wi-Fi signal optimization.

Obtain necessary permits: Research and comply with Federal Aviation Administration (FAA) regulations for drone operation within your airspace.

Training Staff to Work Alongside and Maintain Drones

- Pilot Training (if required): If your chosen drones require a pilot for operation, invest in FAA-approved pilot training for designated staff.

- Maintenance Training: Train staff responsible for maintaining and cleaning drones to ensure optimal performance and lifespan.

- Safety Protocols: Educate all warehouse personnel on safety protocols when drones are in operation, including maintaining clear walkways and using proper communication channels.

Future of Drones in Warehousing

The warehouse drone industry is constantly evolving, with exciting advancements on the horizon:

- Improved Autonomy: Expect drones with enhanced AI capabilities for more sophisticated navigation, task execution, and real-time decision-making.

- Increased Payload Capacity: Advances in battery technology and design will enable drones to carry heavier loads, thereby expanding their functionality.

- Advanced Inventory Management: Drones will integrate seamlessly with warehouse management systems, offering real-time inventory data and facilitating predictive maintenance.

- Security and Surveillance: Drones with advanced cameras and sensors will play a larger role in warehouse security and perimeter monitoring.

Predictions for the Next Decade

In the next decade, drones are poised to become more ubiquitous in warehouses. Expect them to handle a wider range of tasks, from inventory scanning and picking & placing to security patrols and data collection.

Their integration will likely improve warehouse efficiency, safety, and accuracy.

Pilot Training (if required): If your chosen drones require a pilot for operation, invest in FAA-approved pilot training for designated staff.

Maintenance Training: Train staff responsible for maintaining and cleaning drones to ensure optimal performance and lifespan. The data collected will be used for future preventive maintenance via machine learning.

Safety Protocols: Educate all warehouse personnel on safety protocols when drones are in operation, including maintaining clear walkways and using proper communication channels.

Future of Inventory Drones in Warehouse Accuracy

The warehouse drone industry is constantly evolving, with exciting advancements on the horizon:

Improved Autonomy: Expect drones with enhanced AI capabilities for more sophisticated navigation, task execution, and real-time decision-making. This evolution in autonomy is expected to free up warehouse personnel to focus on more value-added tasks by automating routine inventory management and data-gathering processes.

Increased Payload Capacity: Advances in battery technology and design will enable drones to carry heavier loads, thereby expanding their functionality.

Advanced Inventory Management: Drones will integrate seamlessly with warehouse management systems, offering real-time inventory data and facilitating predictive maintenance.

Security and Surveillance: Drones with advanced cameras and sensors will play a larger role in warehouse security and perimeter monitoring.

Inventory Management Predictions for the Next Decade

Over the next decade, drones are expected to become increasingly ubiquitous in warehouse inventory data collection. Expect them to handle a wider range of tasks, from inventory scanning and picking & placing to security patrols and inventory counts.

Their integration will likely improve warehouse efficiency, safety, and accuracy.

Conclusion – Warehouse Automation System Drones

As we’ve seen, drones offer a compelling solution for optimizing warehouse operations. From the DJI Mavic with its high-resolution camera to the fully autonomous Vimaan StorTRACK AIR, there’s a drone solution tailored to meet your specific needs.

By strategically integrating drones, warehouses can achieve faster cycle times, improved inventory, and enhanced worker safety. They can use drone data for cycle counting and other value-added tasks.

The future of warehousing is undoubtedly intertwined with drone technology. Businesses that embrace this innovation will be well-positioned to gain a competitive edge in the years to come.

So, are you ready to take your warehouse operations to new heights?

Consider exploring drones’ potential and watch your efficiency soar.

Take Your Distribution Centers to New Heights

Drones are transforming the warehousing landscape, and we’re just beginning to see the possibilities.

Have you explored drone integration in your warehouse?

We’d love to hear your thoughts and experiences!

Share your comments below.

Are there specific tasks for which drones are well-suited? What challenges have you encountered during implementation?

Want to delve deeper? Check out these resources for further reading on drone technology in industrial applications:

Association for Unmanned Vehicle Systems (AUVSI). This industry association provides a wealth of information on drone technology, including resources specific to warehouse applications.

DroneDeploy. This company offers a cloud-based platform for managing drone data, including tools for mapping, surveying, and analytics – all of which are highly relevant to warehouse operations.

The Federal Aviation Administration (FAA) regulates drone use in the United States. This website provides comprehensive information on drone regulations, including registration requirements and safety guidelines.

By staying informed and exploring the possibilities, you can leverage drone technology to optimize your warehouse operations and gain a competitive edge.

So, let’s keep the conversation going! Share your thoughts and experiences with drones in the comments below.