The Nuts and Bolts of a Distribution Center: 2026 Guide

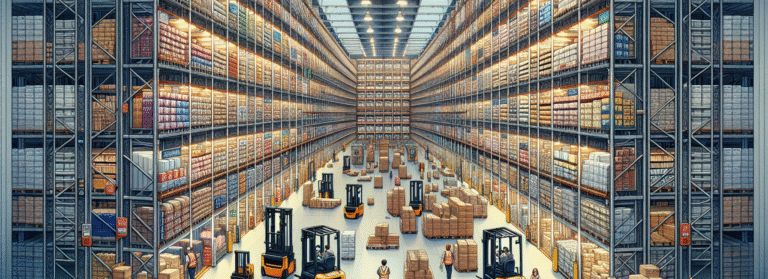

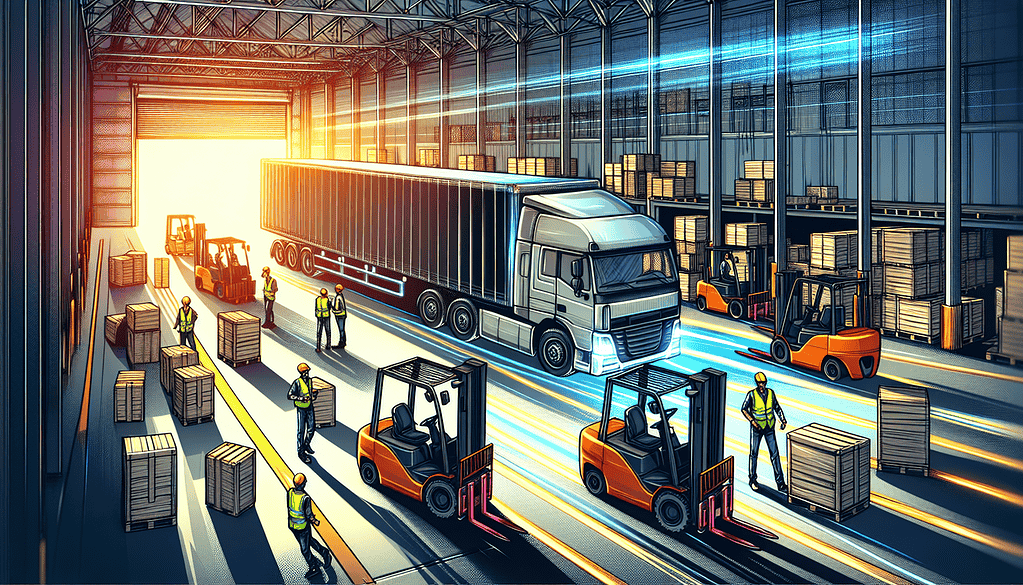

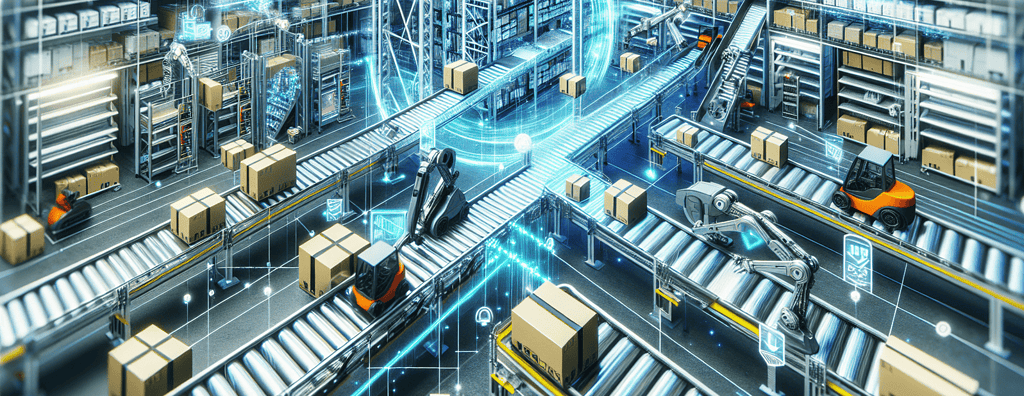

Distribution centers are the backbone of modern supply chains. Unlike traditional warehouses that mainly store goods, distribution centers focus on the efficient flow of products—receiving, sorting, and shipping them quickly to the next destination.

In 2025, their role is evolving. From e-commerce fulfillment to AI-powered automation, these hubs are not just storage facilities—they’re strategic nodes that keep businesses competitive and customers satisfied.

What Is a Distribution Center?

A distribution center (DC) is a facility designed to receive, process, and dispatch goods. Its goal is speed and efficiency, not long-term storage.

Key functions include:

Receiving & inspection of goods.

Storage & organization tailored to turnover speed.

Cross-docking to move items directly from inbound to outbound trucks.

Value-added services like packaging, labeling, or kitting.

Why Distribution Centers Matter

Distribution centers serve as critical links between suppliers, retailers, and end customers. Their benefits include:

Faster order fulfillment and delivery.

Reduced transportation costs through optimal location.

Streamlined inventory management.

Flexibility to handle seasonal peaks.

With consumer expectations for 2-day or even same-day shipping, DCs make speed and reliability possible.

Types of Distribution Centers

Not all DCs are the same. Businesses design them based on customer demand, products, and supply chain strategy:

Retail Distribution Centers

- Deliver bulk shipments to brick-and-mortar stores.

- Often use cross-docking to reduce storage.

- Example: Walmart’s DCs ensure shelves are always stocked.

E-commerce Fulfillment Centers

Handle individual customer orders across wide geographies.

Use advanced picking, packing, and labeling systems.

Essential for companies like Amazon and other online retailers.

Manufacturing Distribution Centers

Support production plants by storing and distributing raw materials or finished goods.

Integrated with Warehouse Management Systems (WMS) to sync with production schedules.

Specialized Distribution Centers

Serve niche markets (e.g., pharmaceuticals with cold storage, food with refrigeration, oversized freight).

Require specialized handling, compliance, and equipment.

Technology in Modern Distribution Centers

Technology is transforming how DCs operate in 2025:

Warehouse Management Systems (WMS): Centralized control of inventory, order processing, and labor management.

Automated Storage & Retrieval Systems (AS/RS): Maximize vertical space and speed up picking.

Automated Guided Vehicles (AGVs) & AMRs: Transport goods with minimal human input.

Barcode & RFID Systems: Enhance Accuracy and Minimize Errors.

AI & Predictive Analytics: Forecast demand surges, optimize slotting, and reduce downtime through predictive maintenance.

Challenges Facing Distribution Centers in 2025

While powerful, DCs face significant headwinds:

Labor shortages & high turnover: A consistent issue that forces investment in training and automation.

Rising costs: Land, energy, and technology adoption drive expenses higher.

Sustainability pressures: Companies must adopt green warehousing practices, including energy-efficient lighting, eco-packaging, and renewable energy integration.

Market volatility: Shifts in demand (like pandemic surges) test supply chain resilience.

Planning and Designing an Efficient Distribution Center

When building or upgrading a DC, companies should focus on:

Location: Proximity to highways, ports, or airports reduces transit time and cost.

Layout & Flow: Clear separation of receiving, storage, and shipping reduces bottlenecks.

Storage Systems: Pallet racking, mezzanines, and vertical storage optimize space.

Safety & Security: Surveillance, controlled access, and employee training protect people and assets.

Scalability: Facilities must be able to adapt to new technologies and market growth.

Jobs in Distribution Centers

A modern DC runs on both people and technology. Common roles include:

Warehouse Managers: Oversee operations, safety, and productivity.

Forklift Operators & Material Handlers: Move inventory across the facility.

Order Pickers & Packers: Fulfill customer or store orders.

Clerks & Coordinators: Handle documentation and shipping schedules.

Quality Inspectors: Ensure compliance with product standards.

Automation is reducing repetitive work, but human oversight remains critical—especially in problem-solving, safety, and customer service.

The Future of Distribution Centers

Looking ahead, DCs will become smarter, greener, and more automated. Expect:

Greater use of AI-driven demand forecasting.

Robotics-as-a-Service (RaaS) models lowering upfront automation costs.

Expansion of dark warehouses—facilities run almost entirely by automation.

Emphasis on sustainability as carbon regulations tighten.

In short, distribution centers will continue to evolve from simple storage hubs into strategic engines of supply chain efficiency.

FAQs About Distribution Centers

What is the difference between a warehouse and a distribution center?

A warehouse primarily stores goods long-term. A distribution center focuses on moving goods quickly through the supply chain.

Do companies need multiple distribution centers?

Yes, if they serve large customer bases across wide geographies. Multiple DCs allow faster shipping and lower costs.

How does technology improve distribution centers?

Automation, WMS, and AI improve speed, accuracy, and labor efficiency while reducing costs.

Conclusion

Distribution centers are no longer just storage facilities—they are dynamic, technology-driven hubs that power global supply chains. In 2025, companies that invest in well-designed, tech-enabled DCs gain a clear advantage: faster delivery, happier customers, and stronger profitability.