The Management of Warehouse: Powerful Secrets for 2026

Efficient management of warehouse operations is the backbone of successful logistics. This article covers the key parts of warehouse optimization. It will help you boost efficiency, cut errors, and streamline processes.

Table of Contents

Discover how to use strong inventory control, labor management, and quality assurance. They can greatly improve your operation’s flow. The focus is on direct application and the latest advancements. Prepare to raise your warehouse from functional to exceptional.

Key Takeaways

Good warehouse management includes inventory control, labor management, and quality. It aims to optimize operations, increase efficiency, and ensure cost-effectiveness.

Integrating Warehouse Management Systems (WMS) is critical. It gets you real-time inventory data. It also streamlines operations and boosts supply chain visibility.

Automation and new tech like AI and IoT in warehouses cut labor costs. It also boosts efficiency and prepares facilities for future industry trends.

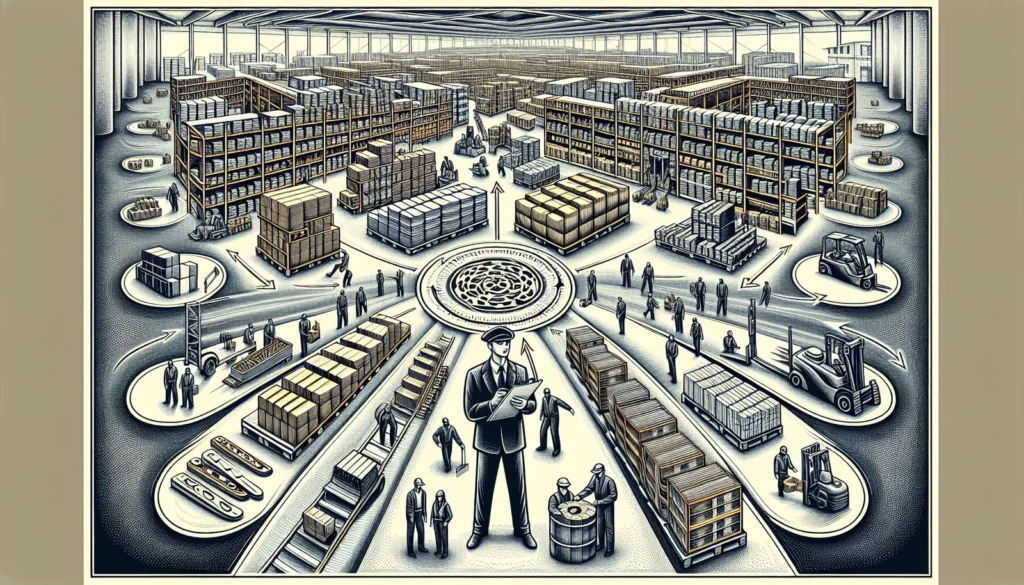

Decoding Warehouse Management

Effective warehouse management includes the organization and optimization of daily workflows. It also includes meticulous inventory handling in a storage facility. This is to foster efficiency and cost savings. The overarching warehouse management process includes various activities such as:

Receipt and proper allocation of goods

Streamlining pick-pack-and-dispatch tasks

Enhancing order through strategic location assignment and comprehensive data analysis

Managing stock is fundamental to efficient operations. It requires careful tracking of items, placing them for easy access, and using the latest metrics for performance evaluation.

This proactive stance allows warehouse overseers to find operation problems quickly. This leads to better function in their whole warehousing system.

Deals on inventory oversight and advanced warehouse software can improve how entities store products. This leads to better operations.

By engaging with deals focused on inventory oversight solutions and deploying advanced warehouse management software tools, entities can refine their overall strategies related to product storage logistics, achieving superior operational outcomes.

The Pillars of Warehouse Operations

Three vital parts make warehouse functions work well. They are inventory control, labor management, and quality control. Together, these elements dictate the efficiency and triumph of all operations.

Inventory Control Mastery

Inventory management is at the core of operations. It focuses on keeping stock levels in perfect harmony with market demands. The aim is to avoid overstocking and understocking. They can cause costly problems from surplus or obsolete stock.

To manage inventory well, firms use various strategies. These include First In, First Out (FIFO), Last In, First Out (LIFO), and Just-In-Time (JIT) approaches. These methods are helped by tools like ABC analysis. They are also helped by Economic Order Quantity (EOQ). They tailor stock management to fit specific business needs and sector norms.

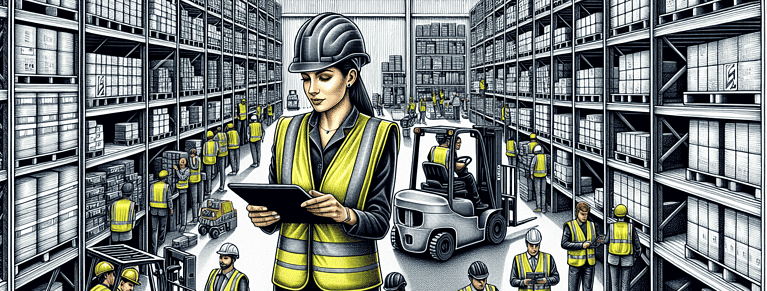

Labor Management Essentials

Another pivotal component of operations is labor management. This includes assigning tasks strategically. It focuses on segments that have high labor costs. This is notably true during picking and packing.

Ongoing training for warehouse staff ensures they are good with modern procedures and standards. It boosts productivity and cuts errors in the warehouse system.

Upholding Quality Control

Upholding stringent quality measures is crucial in warehouse management. Such vigilance ensures compliance with safety standards and regulations. It also reinforces customer satisfaction.

Monitoring the return rate is critical in this sector. It helps find the proportion of goods customers send back.

By watching this indicator, we can find potential problems. They relate to the quality of products and the accuracy of order fulfillment. Then, we can fix the problems.

Streamlining Warehouse Processes

Optimizing the flow of operations is essential for improving overall operational efficiency. You can do this by making procedures standard, using automation, and delegating order fulfillment to third-party logistics providers.

Enhancing Receiving Procedures

The key is the effectiveness of inbound operations. It maintains precise inventory and ideal storage setups. Flawlessly merging products into the warehouse is crucial. It stops errors or holdups that could disrupt the warehouse.

The putaway process is critical for boosting warehouse efficiency. It does this by moving goods from the docking area to their storage location. Performance indicators should be considered to measure and enhance receiving operation performance.

Cost per line for putaway

Cycle time for receiving

Efficiency rate for receiving tasks

Expense incurred per line during receiving

Optimizing Order Fulfillment

Skilled outbound operations have a big impact. They speed up order fulfillment. This includes picking, packing, and dispatching items. These processes are integral to maintaining high levels of customer satisfaction.

Smart picking strategies, like zone, wave, or batch picking, can greatly boost efficiency in these areas.

Packers hold a key position within warehouse management systems. They must securely enclose items in packages. They must affix proper shipping labels. And they must use the right packing materials to ensure safe delivery.

Leveraging Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) play an indispensable role in optimizing operations. These systems deliver:

Instantaneous tracking and visibility of inventory levels

Enhanced efficiency in operations

Better decision-making capabilities regarding inventory management and the processes involved in fulfilling orders.

The Role of WMS in Supply Chain Management

A warehouse management system (WMS) improves inventory tracking precision in supply chain management. It also optimizes warehouse space use and refines order fulfillment processes.

Clients work with third-party logistics providers. They need clear insights into shipments, stock, and transactions. The WMS meets these needs. It has strong communication and data exchange. These improve visibility across the supply chain.

Integrating WMS with Enterprise Resource Planning (ERP)

Warehouse Management Systems can link with ERP systems. They enable synchronized business operations. They do this by aligning warehouse activities with broader company processes.

WMS and ERP collaborate. They create unified logistics workflows. These boost efficiency in all areas, from inventory to order fulfillment.

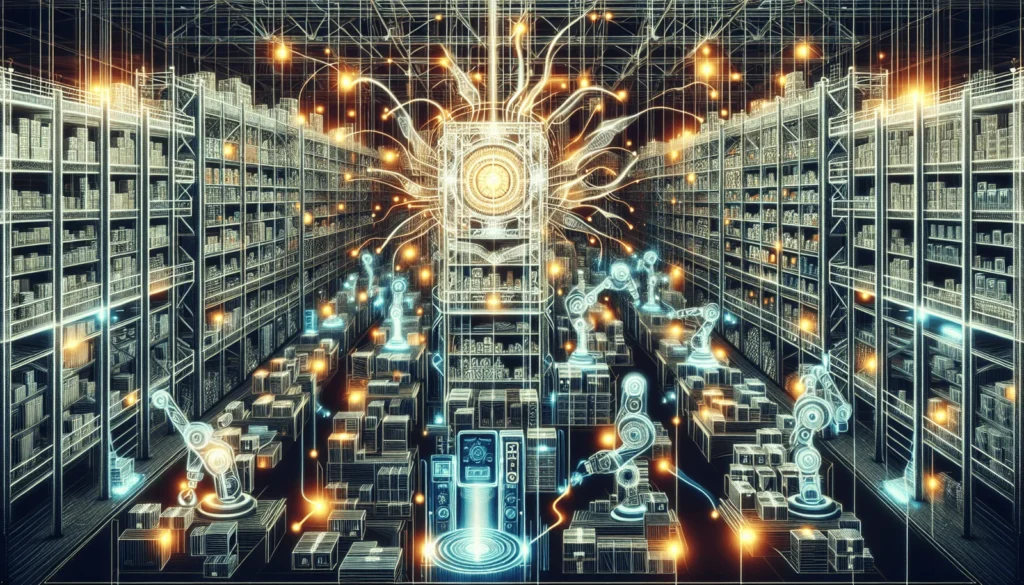

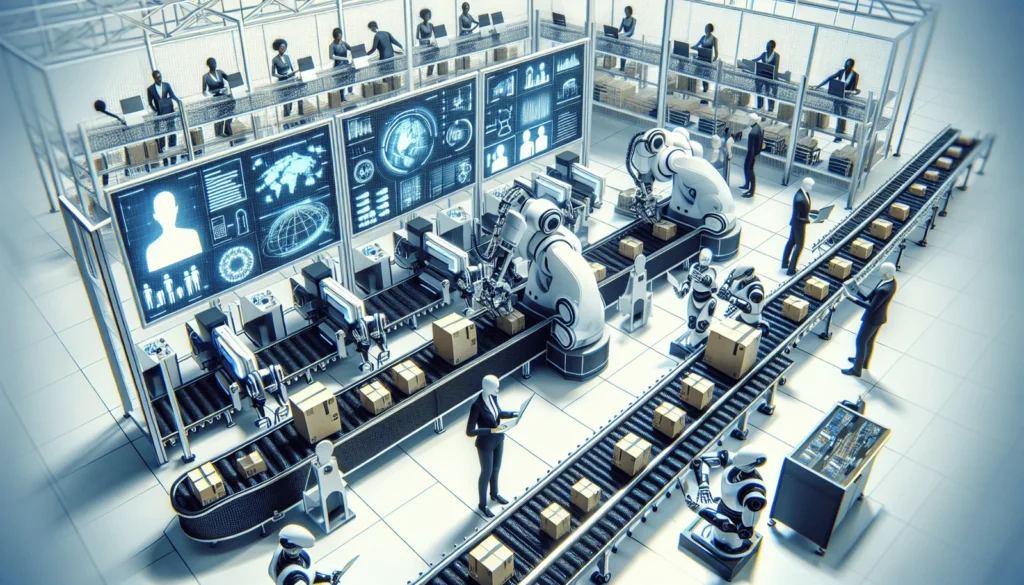

Innovations in Warehouse Automation

Automation technologies have transformed operations. They include conveyor belts, sorting systems, robotic arms, and automated guided vehicles. These innovations reduce employees’ burden of boring tasks and expenses. They also improve the speed and accuracy of fulfillment.

AI and the Internet of Things (IoT) have emerged. They’re causing a in warehouse management. These advancements allow for instantaneous merchandise monitoring. They also enable pull-based supply chain integration. They ensure that automated systems communicate well with each other.

Designing for Efficiency: Warehouse Layout and Space Utilization

Optimizing the layout of a warehouse is crucial for streamlining operations. This optimization is a big one. It can cut travel distances within the facility and reduce congestion.

Doing so accelerates various activities, including receipt, storage, order picking, and dispatching goods.

Adjustable racks and shelves have many advantages. They are great for maximizing storage space.

They increase vertical storage potential.

These systems are adaptable to shifts in inventory levels.

They ease growth within their operational capabilities.

They can suggest clever ways to pick items and store them. They do this by carefully analyzing design and configuration choices.

The occurrence of unused space is lessened thanks to these versatile structures.

Efficiency in operations is greatly improved.

Measuring Success: Key Performance Indicators (KPIs)

KPIs are vital for efficiency and cost-cutting. They offer insights by tracking performance.

Monitoring metrics is vital. The metrics include picking accuracy and order cycle time. They help test and enhance operations’ effectiveness.

We focus on these KPIs. They are used to refine operations in a warehouse. This is to optimize efficiency and manage expenses.

Scaling Up: Managing Many Warehouses and Fulfillment Centers

As businesses grow, managing many warehouses and fulfillment centers becomes a necessity. Outsourcing to third-party logistics (3PL) providers can improve warehouse management across channels. Many warehouses are used to do this. It also involves better logistics and real-time data insights. And it’s done without big investments in technology, infrastructure, or equipment.

However, managing many warehouses comes with challenges such as:

inventory balancing

complex logistics

workforce management complications

security risks

Clear, consistent communication and dedicated channels are critical. They’re key to coordinating operations well and preventing errors across warehouse locations.

Navigating Challenges: Safety and Compliance in Warehouse Management

Ergonomic innovations and technological advancements are key to optimizing safety within warehouse management. Adding these elements to operations cuts worker injuries. It also reduces accidents on site. It improves safety standards and staff morale.

Warehouses must follow safety rules. They also must obey regulations. This involves sticking to set guidelines. It also involves training all staff well. And it includes consistent audits. These measures avoid big fines. They also ensure a safe workplace for employees.

Future-Proofing Your Operation: Trends in Warehouse Management

Warehouse management is changing quickly. AI and IoT are used more. They make warehouse layouts smarter and operations better.

Sustainability is emerging as a vital component of warehouse management. Embracing green practices and sustainable technologies reduces environmental footprints. It shows commitment to ecological responsibility to stakeholders.

Summary – Management of Warehouse

In summary, effective warehouse management is complex. It involves critical parts, such as inventory control, labor management, and quality.

Technology advances have brought automation. They let companies improve by boosting efficiency and cutting costs a lot.

Adopting these innovations helps enterprises expand and triumph in a competitive commercial environment. It future-proofs business operations.

Frequently Asked Questions

Q: What is the role of a warehouse manager?

As a manager, you must oversee the day-to-day activities. This includes inventory and labor management. You must also ensure quality. We do this to improve procedures for greater efficiency.

Q: How can automation improve operations?

Businesses can enhance their operations by adopting automation technologies. These include conveyor belts, sorting systems, robotic arms, and automated guided vehicles. These technologies free staff from boring tasks. They also cut labor costs and speed up work and accuracy.

Q: Why is inventory control important in warehouse management?

Inventory control is important in warehouse management. It helps keep stock at the right levels based on demand. This prevents costly issues from excess or obsolete inventory.

Why should you integrate a Warehouse Management System (WMS) with ERP systems?

Combining a Warehouse Management System (WMS) with ERP systems improves control. It syncs operations with many business functions. It helps unify logistics procedures and simplifies tasks in the organization.

Q: How is the safety of warehouse operations ensured?

The security operation should blend ergonomic planning and advanced technology. It should follow regulatory standards, provide extensive staff training, and conduct consistent audits. This will cut injuries and accidents.

This whole strategy creates a safe atmosphere. It’s for the warehouse staff.