Quality Rack for Warehouse Storage Solutions 2026

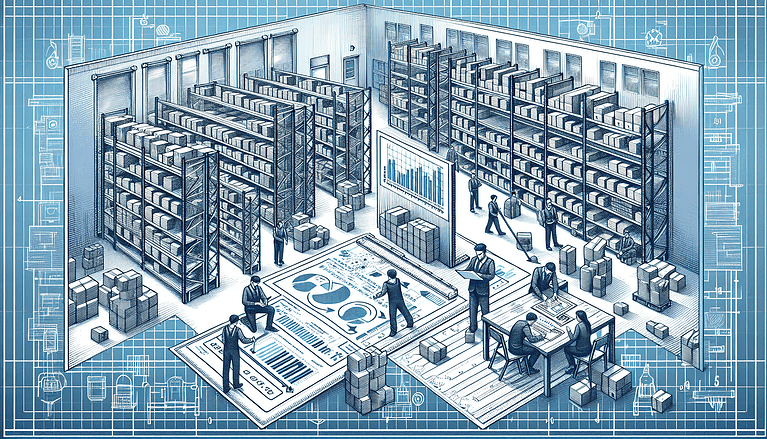

Deciding on a rack for warehouse storage can significantly impact your operational efficiency and space utilization. In this article, we cut through the clutter to explore diverse warehouse racking systems and review how specific features suit various business requirements.

Key Takeaways

- Pallet racks are essential for maximizing warehouse efficiency, vertical space, and improves item accessibility.

- Warehouse racking systems offer tailored solutions for inventory needs, ensuring optimal functionality and space utilization.

- Professional installation and regular maintenance are crucial for the safety and longevity of pallet racking. Expert guidance is needed for setup.

Maximizing Warehouse Storage with Pallet Racks

Imagine a warehouse where every piece of inventory is neatly positioned, readily accessible, and organized—a perfect setup for any enterprise. This can be achieved by using pallet rack shelving as the foundation of an efficient stock management system.

Pallet racks do much more than hold items. They are crucial in constructing an effective storage apparatus that offers both dense product organization and swift access to pallet loads.

These pallet load systems represent not just a method for keeping goods but also embody a tactical approach to managing warehouse inventories, enhancing supply chain processes, and improving business operations.

Table of Contents

Space Utilization

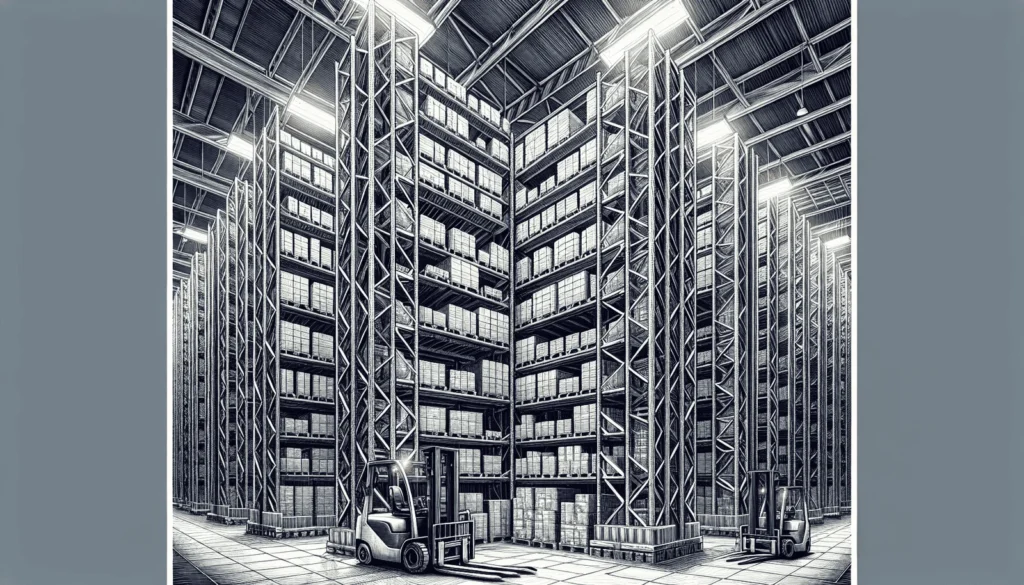

Thanks to pallet racks, the necessity for large warehouses that use excessive land is a thing of the past. These storage racks have revolutionized how companies manage space by allowing them to extend their storage vertically up to the ceiling.

This approach dramatically increases the density of stored goods and maximizes the number of pallets per aisle, all while keeping pallets compactly organized, which minimizes required vertical space. This strategic move paves a new path for businesses looking forward to scaling up without incurring hefty property costs.

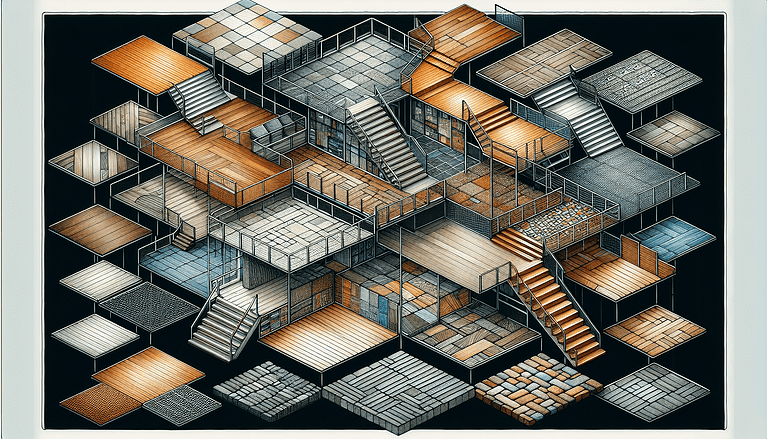

As businesses grow, so does their ability to enhance these rack systems. Storage solutions such as multi-tier racking or pick modules provide layered storage areas complete with stair access for hand-picked orders—optimal use of every cubic foot within the facility’s confines is thus achieved.

Pallet racks offer remarkable flexibility and scalability. They can be conveniently adjusted and expanded in line with business growth strategies, enabling more stock accommodation without major overhauls.

Improved Organization and Accessibility

The strategic arrangement of pallet racks within a warehouse yields numerous advantages, such as:

- Defined aisle spacing, which minimizes the time and labor involved in accessing inventory

- Streamlined warehouse functions that expedite the process of finding and picking items

- A decrease in product misplacement occurrences

- Accelerated procedures for shipping

Within a warehouse’s dynamic environment, pallet flow racks capitalize on gravity to seamlessly move pallets from loading zones to areas designated for picking, increasing storage space and operational productivity.

Push-back pallet racks provide an elegant solution for high-density storage while retaining the versatility to handle various stock-keeping units (SKUs). This system allows each newly introduced load to gently push preceding ones back into the warm confines of the rack.

Types of Rack for Warehouse Optimization

The market today offers an array of pallet racks, each with unique advantages—whether it’s the cost-effective and flexible selective pallet racking system or space-saving double deep racks, as well as efficient carton flow systems designed for every storage strategy.

Available options in the market include:

- Teardrop Pallet Rack

- Selective Pallet Racking

- Double Deep Racks

- Carton Flow Systems

- Cantilever Racks

- Slotted Pallet Rack

Each variant provides an ideal solution catering to diverse storage needs within today’s marketplace.

Every type of rack is meticulously engineered with particular industries and their respective storage intricacies in mind, guaranteeing a suitable warehouse rack option available no matter the inventory or spatial limitations.

Whether accommodating items with rapid turnover rates or storing large and irregularly shaped goods, selecting the correct rack type can facilitate item placement and improve overall efficiency within your warehouse environment.

Teardrop Pallet Rack

Key Features

Design

- The teardrop shape of the holes on the uprights allows for easy adjustment and installation of the beams.

- The wider part of the teardrop hole facilitates the insertion of the beam connector, while the narrower part locks it in place.

Advantages

- Quick to assemble and adjust without additional hardware or tools

- Standardized configurations allow effortless interlocking with parts from various manufacturers

- Can accommodate a wide variety of load sizes and weights and configured to fit specific storage needs (single-deep, double-deep, etc.)

- Flexibility to reconfigure the racking as storage needs change significantly benefits dynamic warehouse environments.

- Beams are typically inserted into the teardrop holes and secured with safety clips

- Reduced installation time and labor costs, with minimal tools required for setup

Components

- Uprights: Vertical columns with teardrop-shaped holes that provide the main structural support for the racking system, typically made of steel for strength and durability.

- Beams: Horizontal bars that connect to the uprights and hold the pallets, come in various lengths and weight capacities, made of rolled steel with a powder-coated finish for corrosion resistance.

Safety Clips/Pins: Small clips or pins secure the beams to the uprights, preventing them from accidentally dislodging, which is essential for safety and stability.

Wire Decking (optional): Metal mesh panels that sit on the beams to provide a stable surface for pallets, preventing smaller items from falling through, enhancing safety, and improving airflow and visibility.

Benefits

- Strength and Durability: Made from high-quality steel, teardrop racking systems are built to last and can handle heavy loads.

- Safety: Secure connections and optional safety accessories (e.g., wire decking, safety clips) enhance the overall safety of the system.

- Cost-Effective: The ease of assembly and ability to reconfigure make teardrop racking a cost-effective solution for many warehouses.

- Space Optimization: The ability to adjust beam heights and configurations helps maximize storage space and improve warehouse efficiency.

Applications

- General Warehousing: Suitable for storing a wide range of products, from heavy machinery to smaller items.

- Distribution Centers: Ideal for environments where quick and easy access to various products is essential.

- Retail: Used in large retail backrooms or storage areas to organize inventory efficiently.

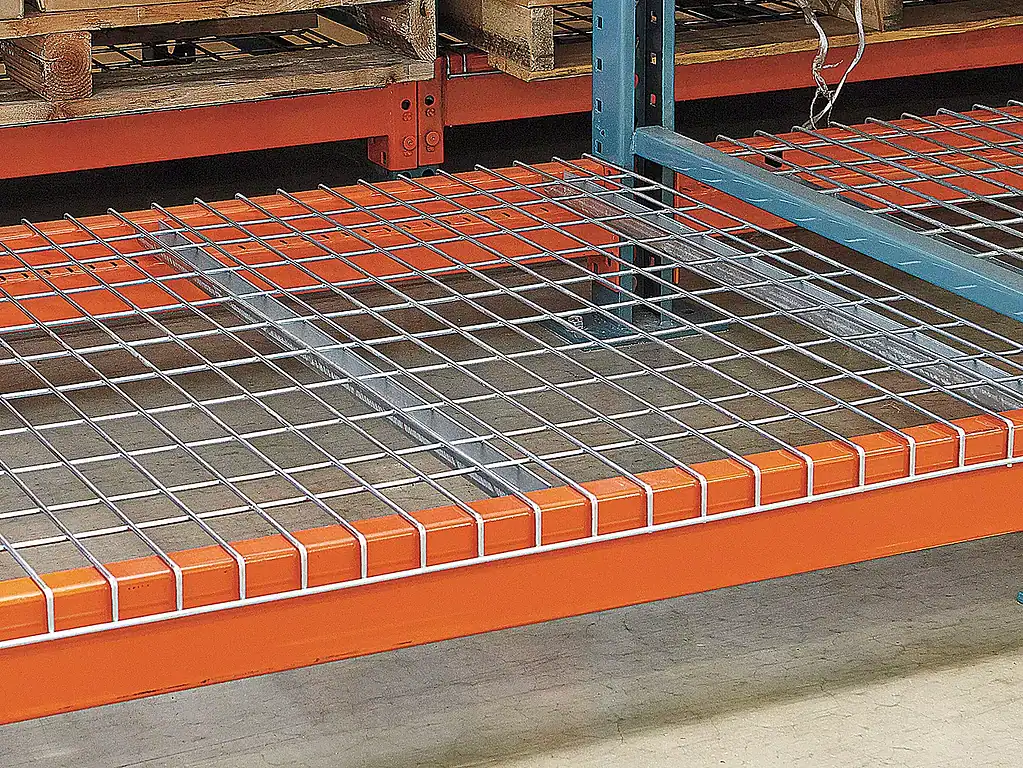

Wire Decking

Pallet racks have seen significant advancements with the addition of wire decking, which provides a stronger and more reliable base for pallets than earlier materials. The mesh design contributes an extra safety measure by maintaining stability and preventing pallets from shifting or falling through the gaps between beams.

Pro Tip: If you choose the wire decking shown above, make sure you order a smaller label. First, you don’t want to bump every piece of grating up to install a label, second, the label will get damaged over time, and third, part of the label will probably get covered by the waterfall deck. I recommend using the ‘drop in’ wire decking unless you are putting tremendous weight on the grating.

Wire decking is essential in warehouse racking systems, supporting stored items and improving safety. Several types of wire decking are designed to meet specific needs and requirements. Here are the main types of wire decking for warehouse racks:

Standard (Flared) Wire Decking

Description: Standard wire decking, also known as flared or waterfall decking, features a U-shaped channel support that fits over the front and back beams of the rack.

Advantages: It is easy to install and provides strong support, and the waterfall edges add extra safety by preventing items from sliding off.

Flush Decking

Description: Flush decking is similar to standard wire decking but does not have waterfall edges. The decking sits flush with the top of the rack beams.

Advantages: It offers a cleaner look and is ideal for applications where the overhang might interfere with the storage or retrieval process.

Inverted Channel Decking

Description: This type of decking has inverted channels that sit inside the beams rather than over them, providing a flat surface.

Advantages: Reduces the risk of debris buildup and is easier to clean, making it suitable for environments requiring high hygiene standards.

Step Channel Decking

Description: Step channel decking has a step-like structure that sits within the step of the rack beams, providing additional support.

Advantages: Enhanced load capacity and stability, ideal for heavy-duty storage applications.

Inside Waterfall Decking

Description: Inside waterfall decking features edges that wrap inside the beams rather than over the top, providing a smooth edge on the outside.

Advantages: It prevents snagging and damage to products and is suitable for applications where product integrity is crucial.

Flat Wire Decking

Description: Flat wire decking has no channels or waterfall edges; it lies flat on the beams.

Advantages: Provides a smooth surface for storage and is often used with other decking types for specific storage needs.

Wire Decking with Support Bars

Description: This type includes additional support bars that run perpendicular to the wire mesh, providing extra strength.

Advantages: Increased load-bearing capacity, suitable for storing heavy or dense items.

Custom or Specialty Decking

Description: Custom wire decking can be designed to meet specific requirements, such as different mesh sizes, finishes, or added safety features.

Advantages: Tailored to specific applications, ensuring optimal performance for unique storage needs.

Each type of wire decking offers distinct advantages, making it important to choose the right one based on the specific requirements of your warehouse racking system and the nature of the items being stored.

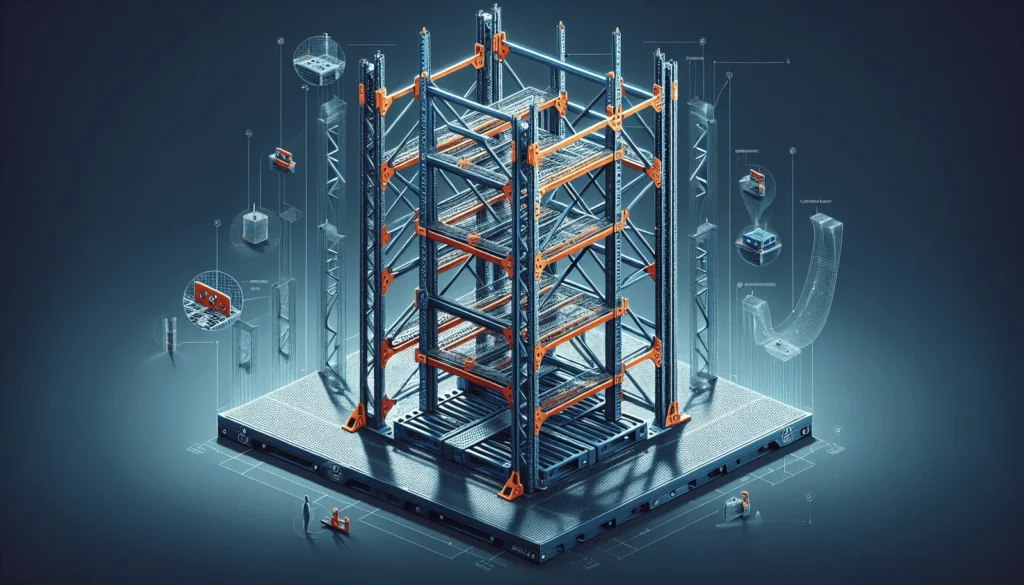

Essential Components of Pallet Racking Systems

Exploring the structure of a pallet racking system exposes its crucial elements, each playing an indispensable role in its overall function. These components consist of:

- Uprights: Serving as the main support for the structure

- Beams: Connecting and supporting to hold up the pallets

- Shelves: Positioned to accommodate goods with readiness

Collectively, these parts create a durable storage framework that can be tailored to meet any warehouse’s specific needs.

Pro Tip: For the safety of personnel, compliance with regulations, maintaining structural integrity, and ensuring quality and liability coverage, it is essential to avoid in-house modifications to racking systems. Always seek professional assistance for any modifications. It’s not worth the risk.

Uprights

Pallet racking systems rely on uprights as their foundational pillars, which are crucial for upholding the unit’s security. As vertical supports are regularly placed throughout the system, these sturdy structures bear the brunt of pallet weights and merchandise by channeling stress down to the warehouse floor.

The uprights of a pallet racking setup depend on its sensibility and load-bearing capability. They are integral in preserving stability and maximum storage capacity.

The versatility inherent in upright designs can be attributed to several features.

- Provision of slots or connectors that facilitate attachment with beams, cross braces, and supplementary components

- A modular nature that enhances overall stiffness while allowing for tailored configurations

- Flexibility that accommodates diverse storage demands

Beams

As the supportive limbs, pallet rack beams evenly disperse the load across them, much like a bridge between uprights. This ensures stability and creates a robust platform for housing inventory.

Two beams must be equipped in unison to constitute one shelf within this framework, underscoring the interdependent nature of these pivotal components in constructing the racking structure.

Shelves

Shelves, typically crafted from robust materials such as wood or metal to endure the burden and usage associated with storage, serve as level platforms on which items are placed.

The configuration of these shelves can differ greatly. Some come with backs that provide additional support, while others are constructed without backs to facilitate convenient access from various directions.

Pallet Rack Accessories: Enhancing Your System

Incorporating appropriate accessories into a pallet racking system can elevate its performance and safety beyond its basic capabilities. These additional components, including safety guards, row spacers, and guides for forklift aisles, act as crucial enhancements that considerably amplify an organization’s efficiency and value.

Top-tier manufacturers such as Husky & Wire, Unarco Rack, and Bulldog Rack provide an extensive selection of commercial racks and accessories. This ensures businesses access superior-quality products tailored to fulfill their precise storage requirements.

Safety Guards

Safety guards are essential in pallet racking, though they often don’t pay attention. They are a vital defense against forklift impacts and help prevent serious rack failures.

These protective components, such as column protectors and guards that cover the ends of rows, defend the framework and boundaries of racks against harm in day-to-day warehouse activities.

Their importance extends beyond safeguarding physical assets—they are instrumental in protecting staff members from potential injuries caused by objects dropping or equipment mishaps.

Enclosures designed for racks—including supplementary add-on units—introduce additional security to warehouse operations. They ensure that pallets and cartons stay firmly on the rack while aiding operators with safer guidance when maneuvering forklifts around these storage systems.

Pro Tip: These are not optional. You must install these to protect your uprights. Tour any warehouse and you will see missing paint on these guards. Yeah.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Row Spacers

Row spacers act as the unseen adhesive, maintaining precise alignment within a pallet racking system. They preserve integrity and stability by guaranteeing uniform spacing between rows of racks.

These compact yet crucial components are essential in securing the racks, diminishing potential dislocation or harm caused by forklift activities.

Forklift Aisle Guides

Forklifts serve as the powerhouse vehicles in a warehouse, navigating the space on predetermined pathways established by aisle guides. Beams situated at floor level are crucial for bolstering the structural integrity of pallet racking systems, thereby facilitating safe and effective maneuverability for these essential pieces of equipment.

Pro Tip: Your equipment operators will round corners. You must have heavy duty guards at the ends of all aisles to push them away from the racking.

Ensuring the strength and reliability of a pallet racking system in a warehouse depends on its design quality and the proficiency of its installation and upkeep.

To utilize professional installation services that adhere to safety standards, including OSHA requirements and local construction regulations. Such meticulous setup reduces accident potential while boosting overall warehouse productivity.

Expert installation and ongoing maintenance maintain any pallet rack arrangement’s durability and consistent functionality. These practices safeguard the structure throughout its use, which proves essential for effective warehouse management.

Expert Guidance

Pallet racking systems may seem overwhelming, but with proficient advice, companies can select a setup that meets their strategic goals and bolsters their expansion path. Specialists contribute abundant expertise, providing counsel that enables firms to make enlightened choices concerning their storage options.

Proper Installation

Ensuring the correct assembly of a pallet racking system is crucial for its safe operation and functional efficiency. Improper installation may cause vulnerabilities in the structure, increasing accident risks and detracting from the system’s small effect systems.

The process involves far more than simply connecting components. It involves constructing a solid base that maximizes space utilization while conforming to established safety protocols, an expertise refined over one hundred years.

Pro Tip: Testing your concrete before installing racking is a critical step that ensures the safety, stability, and durability of your warehouse operations. It helps prevent structural failures, ensures compliance with standards, protects personnel, and avoids costly repairs and downtime. You must ensure this occurs before install.

Regular Maintenance

Routine upkeep is vital for a pallet racking system, keeping it operating optimally. Through consistent examinations and maintenance of the system, companies can:

- Avert possible safety risks

- Circumvent costly mishaps

- Preserve operational effectiveness

- Prolong the durability of the racking structure

- Ensure sustained value and dependability

Adopting this preventative strategy is crucial in sustaining effective performance and extended service life for your pallet racking systems.

Pro Tip: Any rack damage must be reported immediately to the management team. I don’t care who did what or who ‘snitched’ on who. If the rack collapses people will get hurt. Safety comes first.

Summary

Pallet racks are a hallmark of ingenuity and productivity in the warehouse setting. They are dedicated to amplifying vertical storage space while improving organization and ease of access.

Assessing rack varieties, their fundamental elements, and crucial accompanying accessories is key to transforming storage efficiency. Professional installation and upkeep are the cornerstones to capitalize on your space fully.

Frequently Asked Questions

What is warehouse shelving vs racking?

Shelving in warehouses is intended to store lighter goods, such as boxes containing paper or minor hardware components. Conversely, racking systems are built to accommodate heavier objects, such as supplies on pallets or bulky equipment.

Thus, the primary distinction between them hinges upon the type of items they are designed to store.

What are warehouse storage racks called?

These storage solutions, called pallet racks or warehouse racking systems, are widely used in numerous warehouses to house inventory.

What are the key benefits of implementing pallet racks in my warehouse?

Incorporating pallet racks within your warehouse can elevate the utilization of vertical space, augment storage capacity, refine organization, and boost overall efficiency. This approach is an excellent strategy for capitalizing on available floor space while ensuring that inventory remains readily accessible.

Can pallet racking systems be customized to fit my specific storage needs?

Indeed, pallet racking systems are customizable to meet your facility’s unique storage requirements. They provide the versatility to adapt and scale with your business and align with your warehouse layout.

What types of items are best stored on heavy-duty storage racks?

Storage racks designed for heavy-duty use are ideal for stashing bulky, hefty items or objects with irregular shapes in numerous sectors for extended periods.