Warehouse Services: Comprehensive Guide for Business 2026

Get under the hood of commerce. They are the unseen gears that keep the modern market moving. Discover the hidden role of warehouse services in your business’s success.

In this easy to read guide we’ll show you the power of warehousing. It’s more than storage. It’s the silent engine of the global economy.

How Warehouse Services Drive Business

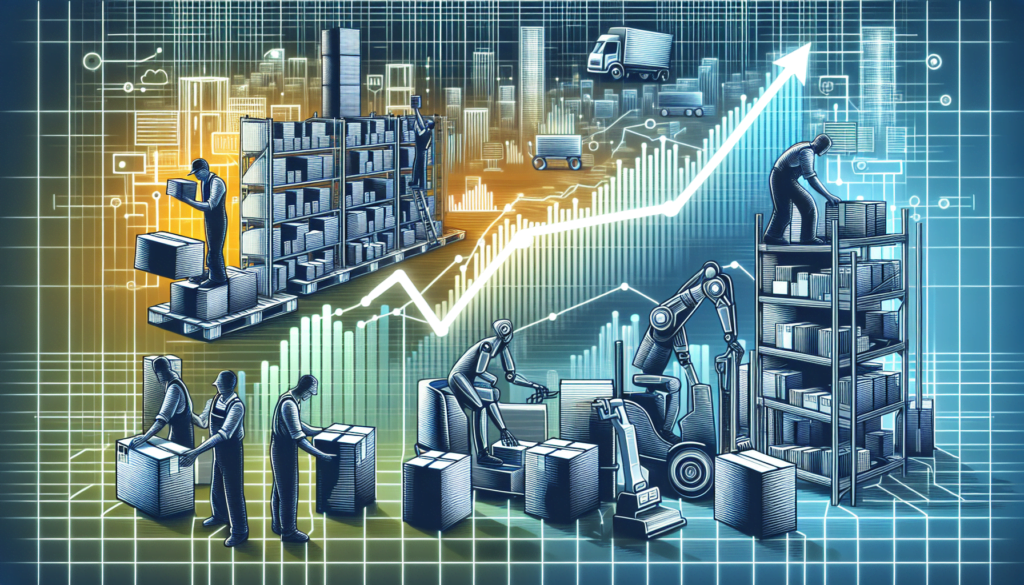

The world of commerce is changing fast, and customers expect a lot. They want faster delivery, more products, and seamless omnichannel experiences. In this fast-paced world, traditional warehousing can’t keep up.

Warehouse services have evolved to meet the needs of modern business. Storage facilities are no longer static. Today’s warehouses are dynamic hubs that use the latest technology and processes to improve efficiency, accuracy, and speed.

Using top warehouse services isn’t nice to have. It’s a must-have. Businesses that use these services can cut costs and operations, save big, and deliver a better customer experience. This is what it’s all about now.

This guide will show you the power of modern warehouse services. We’ll cover the latest trends and real-life examples and teach you how to use these services to grow your business.

The New Era of Warehouse Services

In today’s fast paced market businesses need warehousing solutions that can scale and adapt to their changing needs. Traditional warehousing models can’t scale and flex when it comes to flexibility and scalability.

Modern warehousing services however offer a range of options that can be customized to meet your business needs. This includes the ability to scale up or down quickly based on demand and the flexibility to store different types of inventory and storage needs.

Customized warehousing solutions are key to supply chain management, faster delivery and better customer experience.

What is Modern Warehousing

Modern warehousing is more than dusty storage spaces filled with static inventory. Today’s warehouses are smart environments. These solutions are designed and equipped to meet your business needs. Here’s what modern warehousing means:

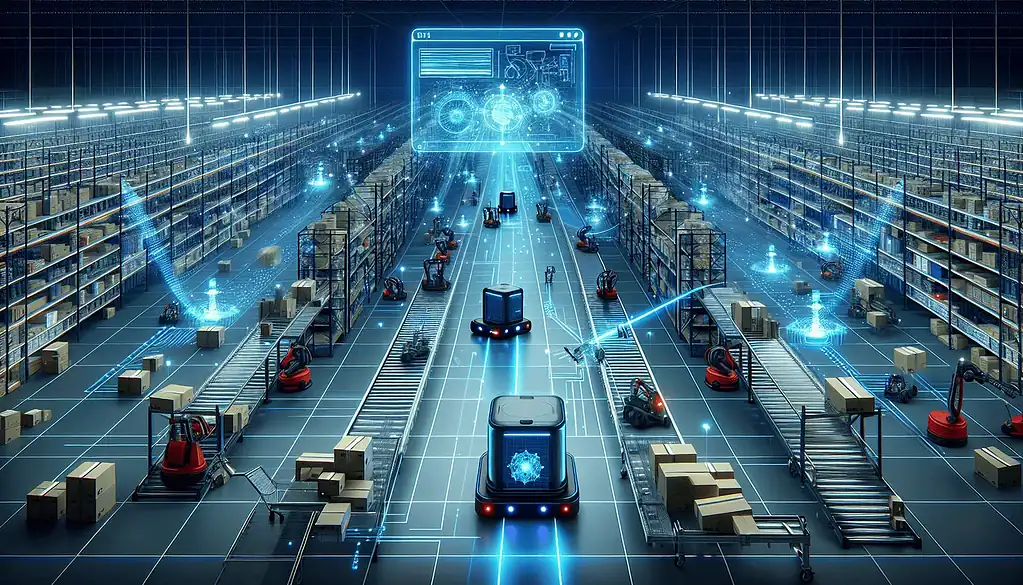

Technology Driven Operations

Manual processes are over. Warehouses now use automation, robotics, and warehouse management systems (WMS) to store, pick, pack, and display real-time inventory.

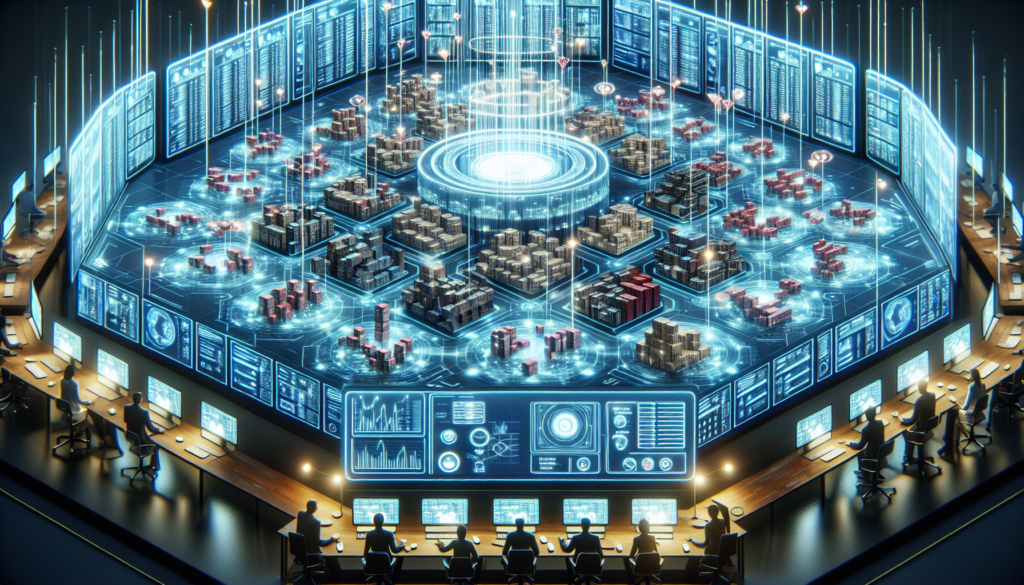

Data for Decision Making

Modern warehouses use data to their advantage. Businesses can adjust inventory levels. They do this by looking at customer demand trends. They look at stock movement and fulfillment times. They can optimize storage layouts and find areas to improve.

Scale and Flexibility

Modern warehousing solutions are designed to scale with your business. You may have seasonal fluctuations or unexpected growth spikes. A good warehouse can grow or shrink to fit your changing needs.

Customer Focused

Warehouses are no longer silos in the supply chain. Modern operations are all about order fulfillment. Fast and accurate delivery that meets (and beats) customer expectations. Plus, they offer services like order picking, packing, labeling, and shipping to cater to specific business needs.

Industry-Specific Warehousing Explained

Modern warehousing is great because it can serve many industries. Gone are the days of one-size-fits-all. Here’s a look at how warehousing is tailored for different industries:

E-commerce

Warehouses for e-commerce businesses are all about fast order fulfillment. They often use multi-order picking and packing systems to handle multiple orders. Inventory management is key to ensuring a seamless online shopping experience.

Manufacturing

Warehouses support manufacturing. They often store larger, bulkier items, integrate with production schedules, and may also have quality control or special storage for hazardous materials. They also store and distribute raw materials to ensure a smooth supply chain for car manufacturers and other industries.

Food and Beverage

Food and drink warehousing requires temperature control, strict hygiene rules, and FIFO inventory management. These warehouses ensure product quality and freshness throughout the supply chain.

Pharmaceuticals

Pharmaceutical warehousing requires strict regulations, temperature control, and special security measures. These facilities focus on storing and tracking medication and supplies.

Knowing these industry-specific requirements helps businesses. They can use warehousing solutions designed for their business, which will optimize operations.

E-Commerce and Warehousing: A Match Made in Heaven

E-commerce businesses rely on warehousing solutions to manage their inventory and get products to customers on time. A fulfillment center can provide custom warehousing services to your business, including order tracking, shipping, and customer satisfaction. Using technology and streamlined processes, they can handle products and shipments quickly and accurately.

Fulfillment centers are key to efficient order storage and processing. They offer services for different types of products, so they are essential for businesses looking to optimize their logistics. Research 3PL companies and understand the strengths and weaknesses of fulfillment centers for your industry, which are crucial to optimizing operations.

Fulfillment Centres: The Core of the Retail Supply Chain

Any e-commerce business’s success depends on giving customers a smooth experience and satisfaction. Warehouses are key to this. They are the heart of online retail. Here’s how:

Inventory Management: Warehouses manage inventory levels to meet customer demand. They receive incoming shipments, organize inventory for efficient picking, and track stock quickly to prevent stockouts and overstocking.

Order Fulfillment: The warehouse springs into action once an order is placed. Picking and packing teams locate and assemble the ordered items. They ensure accuracy and proper packaging for safe transport. Warehouses offer fulfillment services like picking, packing, shipping, storage, kitting, inventory management, and cross-docking.

Warehouses work with shipping carriers to ensure orders are delivered on time and at the right price. They track shipments and inform customers of the delivery status, which builds trust and brand loyalty.

Technology Integration: The Foundation of Efficiency

E-commerce platforms and warehouses need to be connected. This is where order fulfillment happens.

- APIs allow real-time communication and link e-commerce platforms and warehouse management systems (WMS). Orders placed online trigger picking and packing in the warehouse, no manual data entry, and no errors.

Inventory Management Software: WMS software gives real-time inventory visibility. Businesses can track stock levels across multiple locations and optimize stock allocation to fill orders faster.

Warehouse Automation Robotics and automation technologies are increasingly used in e-commerce warehouses. Automated picking and packing systems speed up order fulfillment, reduce manual labor, and ensure accuracy.

Robotics and Automation in Warehousing

Robotics and artificial intelligence (AI) are changing the warehouse landscape. Here’s how:

Automated Picking and Packing: Vision-equipped robots can find and pick items from shelves, reducing labor costs and errors.

AMRs are intelligent robots that can navigate the warehouse, move goods, fulfill replenishment requests, and streamline workflows.

AI-powered Inventory Management: AI algorithms can analyze sales history. They can predict future demand shifts so you can plan your inventory better.

Robotics and AI brings many benefits:

Automation makes it more efficient. It frees workers from repetitive tasks so they can focus on higher-level tasks like quality control and problem-solving.

Robots increase accuracy. They reduce picking and packing errors, meaning fewer order issues and happier customers.

Improved Safety: Robots can protect workers from injuries by automating hazardous tasks.

The Software Revolution in Inventory Management

Warehouse management systems (WMS) are the foundation of modern warehousing. These software solutions offer:

Inventory Tracking and Management gives real-time visibility into stock levels across multiple locations. This visibility allows for optimized storage and order fulfillment.

Order Management simplifies the order fulfillment process. It covers picking, packing, shipping, and tracking.

Labor Management: Optimize employee schedules and workload distribution based on real-time warehouse activity.

Plus, cloud-based WMS solutions bring:

Scalability: Cloud-based systems can grow with your business without big IT investments.

Warehouse teams can access data from any internet-connected device and manage operations, increasing mobility and flexibility.

Cost-Effective: Cloud solutions eliminate the need for expensive on-premise hardware and software installations.

Location for Warehouse Services

When choosing the location for your warehouse, consider the proximity to key transportation hubs such as highways, ports, and railways.

Also, consider a location with access to a storage facility that can provide secure and temperature-controlled storage for goods with non-standard requirements, such as medical, hazardous, and perishable goods.

This will ensure your products are stored safely and efficiently and reduce the risk of damage and loss.

Another factor is the amount of storage space within the warehouse. Specialized storage facilities and warehouses often have unique features such as security and temperature control to cater to different goods.

This can impact your supply chain management and the overall cost of warehousing and distribution.

Where to Warehouse

Your warehouse location affects your distribution efficiency and overall logistics costs. Here’s why location matters:

Warehouses are near customer hubs. They can deliver faster and cheaper.

Easy access to major highways, airports, and seaports means products can be moved quickly and on time.

Warehouses in areas with a ready workforce means you have enough staff to operate efficiently.

Regional Warehousing: California

Regional factors can impact how warehouse services are applied. Here’s California as an example:

High Cost of Living: Warehousing costs in California are higher than in other parts of the US. Businesses may consider multi-warehousing strategies. They would use smaller, well-located facilities to balance distribution needs with cost.

Seismic Zone: Warehouses in California require stricter building codes to withstand earthquakes. Consider this when choosing a warehouse location and designing storage layouts.

Access to International Trade: California has major ports like Los Angeles and Long Beach. These are ideal locations for warehouses that handle imports and exports.

Sustainability and Scalability in Warehousing

Eco-Friendly Warehousing

Warehouse Initiatives

Warehouse operations are going green more often. Here are some of the key trends:

Warehouse design includes energy saving features such as LED lighting, efficient HVAC systems and natural light.

Sustainable Packaging uses eco-friendly materials like recycled cardboard and biodegradable peanuts to reduce environmental impact.

Choosing fuel efficient vehicles and optimising delivery routes minimises transport emissions.

Warehouses for Business Growth

Scalable warehouse solutions are crucial for businesses with fluctuating demand. Here’s why flexibility matters:

Warehouses need to accommodate more storage in peak seasons without disrupting business as usual.

Scalable solutions means businesses can expand easily, add more warehouse space or services as they grow.

Warehouses need to adapt to changing business needs, change storage layouts and add new technologies.

Customer Satisfaction Through Partnership

Partnering with the right warehouse service provider can impact your business and customer satisfaction. 3PL warehousing services can reduce warehouse fulfillment and shipping costs and improve operations and industry expertise.

When choosing a partner, consider the range of fulfillment services they offer, such as picking, packing, labeling, inventory management, and order processing. These services can improve operational efficiency and meet customer expectations.

Timely delivery is key to meeting customer expectations and satisfaction. 3PL warehousing services can help with efficient and on-time delivery so you can manage your logistics well.

Warehouse service providers offer inventory management, storage, value-added services, distribution, logistics, transportation, and order fulfillment. Choose the right one for your business’s long-term growth and success.

Warehousing companies offer storage, fulfillment, distribution, and value-added services. Using these companies can result in cost savings and operational efficiency benefits.

Warehousing services are key to efficient supply chain management and can benefit various industries and businesses. 3PL warehouse services meet customer demand and improve operational efficiency.

Additional Considerations

Security: This includes access control, surveillance systems, and fire safety.

Cost is important. But prioritizing it over reliability and service quality is not a good idea. Get quotes from many providers and ensure they cover all the services you need.

Strong communication is key. Choose a responsive, transparent, and proactive partner in keeping you informed.

Review the contract terms carefully. They include the pricing structure, service level agreements (SLAs), termination clauses, and insurance coverage.

Consider these extra factors. They will help you pick a warehouse partner that fits your needs and helps you meet your goals.