Warehouse Manager System: Make Life Easier with Success in 2026

Navigating a warehouse manager system (WMS) can feel overwhelming. You need software that not only solves today’s challenges but also adapts to tomorrow’s growth. The right WMS streamlines operations, cuts costs, and positions your business ahead of the curve.

Key Takeaways

- WMS is the backbone of modern warehouse operations — boosting accuracy, efficiency, and space utilization.

- Real-time tracking, automation, and integration reduce errors and labor costs.

- Scalability and flexibility ensure your WMS grows with your business.

- AI, IoT, and cloud technologies will define the future of WMS.

Essentials of a WMS

A robust WMS transforms chaotic storage into organized and efficient operations. Its core functions include:

Real-time inventory tracking

Barcode and RFID integration

Pick-and-pack automation

Reporting and KPI dashboards

With these tools, warehouse managers can maintain optimal stock levels, process orders more efficiently, and achieve cross-channel fulfillment with confidence.

Real-Time Inventory Control

Modern WMS replaces infrequent counts with continuous visibility. Technologies like RFID, barcode scanning, and even blockchain improve:

Inventory accuracy

Dispatch speed

Traceability and compliance

The result? Fewer errors, stronger compliance, and more reliable order fulfillment.

Strategies to Minimize Errors

Discrepancies erode trust. WMS helps by:

Triggering alerts for low stock to prevent shortages or overstock.

Supporting cycle counts for continuous accuracy.

Enabling lot and date code tracking to meet compliance standards.

Vendors like Tecsys offer specialized solutions for industries where accuracy is mission-critical, such as healthcare.

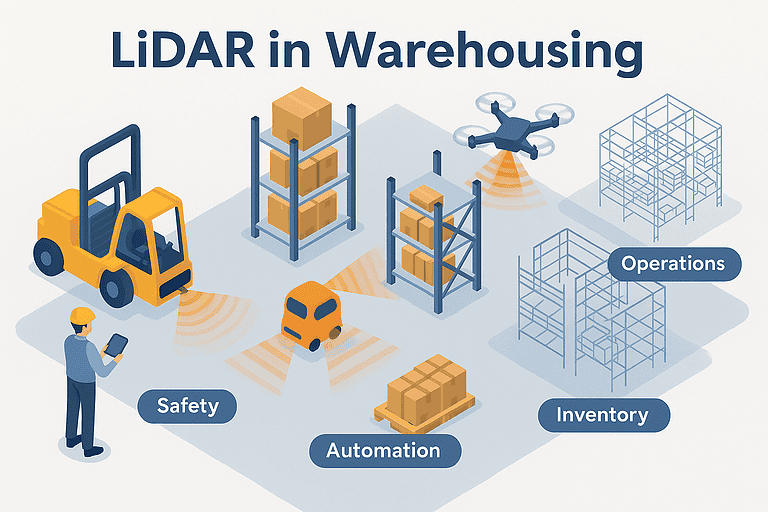

Efficiency Through Automation

Automation turns warehouses into high-performance engines. A WMS integrates seamlessly with:

Conveyor systems

Pick-to-light and pick-to-voice tools

Robotics and ASRS (Automated Storage and Retrieval Systems)

This boosts productivity, reduces errors, and creates a safer workplace.

Cloud-Based WMS: A Game Changer

Cloud platforms like Oracle Warehouse Management Cloud and Logiwa offer:

Remote, real-time access

Lower infrastructure costs

Easy scaling for multiple sites

Faster implementation vs. on-premise systems

Adoption is accelerating because cloud WMS makes advanced tools accessible to mid-sized businesses.

Integrating WMS Across the Supply Chain

A WMS is most powerful when it connects with:

ERP systems (finance, HR, procurement)

3PL providers (multi-client operations)

Transportation systems (route optimization, dock scheduling)

Integration creates a single source of truth, optimizing everything from inbound to outbound.

User Experience & Training

The best WMS combines power with simplicity. Look for:

Intuitive interfaces

Customizable dashboards

Strong training and vendor support (e.g., Cadre Technologies offers VR/AR training and self-paced learning)

Ease of use drives adoption — and ROI.

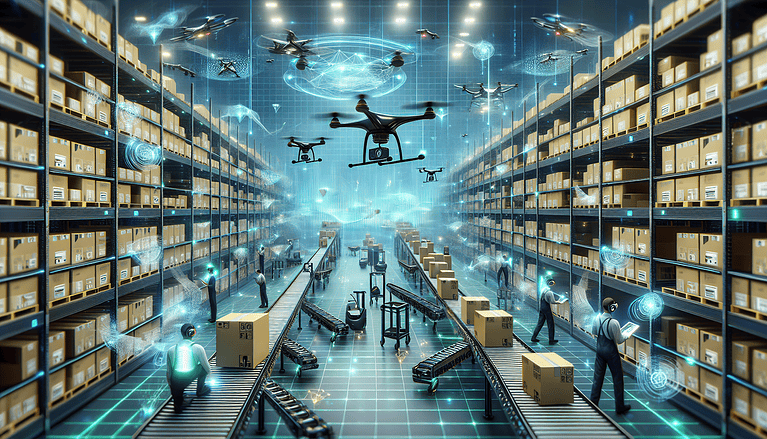

The Future of WMS

WMS will evolve through:

AI forecasting to predict demand and optimize slotting

IoT sensors & digital twins for real-time visibility

Wearables & AR/VR for workforce training and safety

Mobile-first design for on-the-go management

Together, these technologies will create warehouses that are smarter, safer, and faster.

Conclusion

A warehouse manager system is no longer optional — it’s the foundation of modern supply chains. By embracing WMS today and preparing for AI, IoT, and cloud tomorrow, your operation can achieve new levels of accuracy, speed, and scalability. The future of warehousing belongs to businesses ready to invest in systems that adapt and grow.

Frequently Asked Questions

What are the key advantages of implementing a WMS?

Utilizing a Warehouse Management System (WMS) can enhance your business operations. It can help with supply chain management. It can also achieve cost savings. This improvement comes from lower labor costs. It also comes from better inventory tracking accuracy. It comes from automating manual processes. And it comes from making fewer mistakes. All these factors contribute to the company’s increased profits.

How does WMS contribute to inventory control?

A warehouse management system (WMS) is vital for inventory control. It offers real-time tracking, notifications for depleted stock, and consistent cycle counting. It helps preserve precise inventory levels and minimize variances. This enhances inventory administration. It reduces the likelihood of system errors.

Can WMS integrate with material handling equipment?

Indeed, WMS can sync with handling equipment. However, it may require an interface for each system it connects to.

What is the importance of scalability in WMS?

WMS’s scalability is critical. The system seamlessly integrates scale and issue resolution. It adds more users, warehouses, and locations without overburdening itself. This capability is vital for maintaining flexibility and securing sustained success.

How will AI and IoT shape the future of WMS?

TAI and IoT will change WMS. They will enhance efficiency and facilitate prompt decisions. These technologies will also refine operations with predictive analytics. They will ensure real-time tracking in warehouses. This transforms warehouse management with instant insight into operations.