Warehouse Inventory 2026: Strategies, Solutions, and Success

How do online retailers deliver a box of kitty litter or a yoga mat to your doorstep in just a few days? The answer is warehouse inventory management — the engine that keeps fulfillment operations running smoothly. When done right, it ensures the right products are in the right place at the right time, keeping customers happy and businesses profitable.

Key Takeaways

A well-designed warehouse layout and a Warehouse Management System (WMS) are essential for efficiency.

Data analytics and real-time visibility drive smarter decisions.

Proven techniques, such as ABC analysis, safety stock, and cycle counting, help maintain accurate inventory levels.

Staying ahead of automation, AI, and IoT trends is essential for long-term competitiveness.

Warehouse Inventory Management Systems

A WMS is more than a digital stock tracker. It optimizes layout, guides picking, manages stock levels, and generates insights. Key benefits include:

Increased efficiency and productivity

Improved order accuracy

Reduced carrying costs

Enhanced customer satisfaction

By automating manual tasks, a WMS frees staff for higher-value work and reduces errors in picking and packing.

Best Practices for Managing Warehouse Inventory

1. Appoint a Warehouse Inventory Manager

The inventory manager is your quarterback, overseeing receiving, storage, picking, packing, and shipping. The right leader combines operational expertise with a deep understanding of inventory best practices.

2. Optimize Warehouse Layout

Your floor plan has a direct impact on speed and safety.

Use vertical space with racking and shelving.

Store high-demand items at waist level for faster picks.

Keep aisles wide and uncluttered.

3. Establish Clear Workflows

Map every step from order receipt to shipping. Standardized workflows reduce errors, keep teams aligned, and shorten fulfillment times.

4. Implement Inventory Management Software

Pair your layout and people with the right software tools to automate tasks, track accuracy, and generate insights.

Future Trends in Warehouse Inventory Management

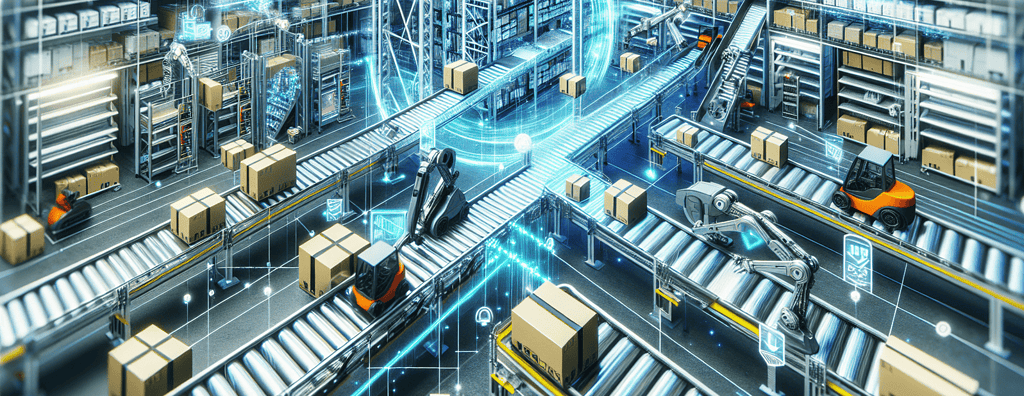

Current Shifts

E-commerce pressure is driving faster fulfillment and tech adoption.

Data analytics guide better inventory decisions.

Automation improves accuracy and throughput.

What’s Next

AI will predict demand, optimize slotting, and guide labor.

Robotics will handle more tasks related to picking, packing, and transportation.

IoT devices will track inventory in real-time and enhance safety.

Choosing the Right Inventory Management Solution

When evaluating a WMS or IMS, consider:

Features: tracking, picking, reporting, analytics, and integration.

Scalability: grows with your operation.

Ease of use: intuitive for staff at every level.

Cost: balance investment with ROI.

Support: choose vendors with strong implementation services.

Align your solution with your business needs — not just industry buzzwords.

Inventory Management Techniques

Demand Forecasting

Utilize historical data, seasonality, and trends to accurately predict demand and prevent stockouts.

ABC Analysis

A items = high-value, low-volume. Count and monitor often.

B items = moderate value. Standard controls apply.

C items = low-value, high-volume. Simplify controls.

Safety Stock

Buffer inventory protects against demand spikes or supplier delays.

Cycle Counting

Count smaller inventory segments regularly to maintain accurate records without disrupting operations.

Vendor-Managed Inventory (VMI)

Suppliers manage your inventory levels directly, freeing you to focus on operations.

Warehouse Management Software: The Game Changer

Modern WMS systems go far beyond spreadsheets. They centralize tasks such as:

Real-time inventory tracking

Order picking and packing

Reporting and analytics

Layout optimization

The payoff: fewer stockouts, faster fulfillment, lower labor costs, and actionable insights.

Integrating IMS and WMS

When Inventory Management Systems (IMS) and Warehouse Management Systems (WMS) integrate:

Orders are more accurate

Stockouts drop

Inventory allocation improves

Steps to integrate:

Standardize product codes and data

Map data flows between systems

Test thoroughly before going live

Maintain continuously to ensure accuracy

Conclusion

Warehouse inventory management is the foundation of efficient fulfillment. By combining best practices, the right technology, and proven techniques, your warehouse can operate leanly, accurately, and remain future-ready.

Frequently Asked Questions

What is inventory management?

It’s the oversight of goods from purchase to sale — ordering, receiving, storing, tracking, and shipping.

Why is inventory management important?

It improves profitability, cash flow, and customer satisfaction by balancing supply with demand.

What are the benefits of good inventory management?

Increased sales and profitability

Reduced carrying costs

Optimized warehouse space utilization

Fewer stockouts

What are common mistakes?

Overstocking, understocking, poor layout, inaccurate records, and failing to leverage technology.

What’s the difference between inventory management and warehouse management?

Inventory management covers the entire supply chain. Warehouse management focuses on the movement and storage of goods within the warehouse.

How can I improve my inventory management?

Implement a WMS, conduct audits, forecast demand, set min/max levels, optimize layout, and partner effectively with suppliers.