Forklift in Warehouse Operations: Best Practices for 2026

Selecting the appropriate forklift for your warehouse requirements is essential to enhancing efficiency and ensuring safety. This article details various types of forklifts ideal for diverse warehouse settings and emphasizes the importance of adhering to safety measures. Let’s look into the best forklift in warehouse operations today.

Table of Contents

Forklift Types for Warehouse Optimization

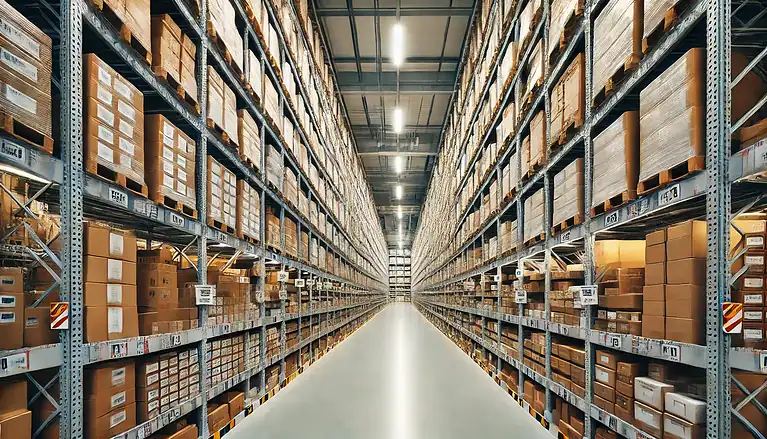

Within the expansive confines of a warehouse, an appropriate forklift is a vital navigator capable of moving through aisles deftly and accurately. Various forklifts, including the forklift truck, are currently on the market, each meticulously crafted to enhance warehouse functionality.

Fork trucks are crucial in material handling and require specific warehouse designs to accommodate their maneuvering needs.

Among these, the walkie stacker stands out for its efficiency in moving inventory within warehouses and distribution centers. Every kind of forklift offers distinct features suited to particular tasks and configurations within different warehouses, from the reliable everyday model to those specialized models designed for narrow aisle work.

The range of load capacities available for different forklifts ensures versatility in handling various tasks, from typical warehouse settings to lifting heavier loads. Let’s review the forklift fleet.

Standard Electric Forklifts

The electric forklift is an essential component of the equipment array in a warehouse and is critical to its operations. These machines typically range from 4 to 7 feet wide and extend from 8 to 10 feet long, dimensions that are optimal for navigating the standard spaces within a warehouse.

One notable feature of the electric forklift is the counterbalance weight situated at the rear end. This design facilitates their primary function: maintaining equilibrium while carrying heavy loads. This is indispensable when moving materials and handling pallets when loading or unloading them.

Electric Pallet Trucks

Electric pallet, lift, and pump trucks, including pallet jacks, are indispensable for efficiently moving small loads in confined areas. These vehicles excel at short-distance product transport and facilitate swift unloading from delivery trucks, underscoring their value within indoor settings.

Narrow Aisle Forklifts

In the tight spaces of warehouse aisles, a forklift that can deftly move and easily pivot is essential. This is where narrow aisle trucks come into play—these machines are tailored to operate within cramped quarters.

The lineup includes models like turret trucks and 3-wheel counterbalance lifts, all crafted to enhance storage capacity and efficiency in settings with narrow aisles.

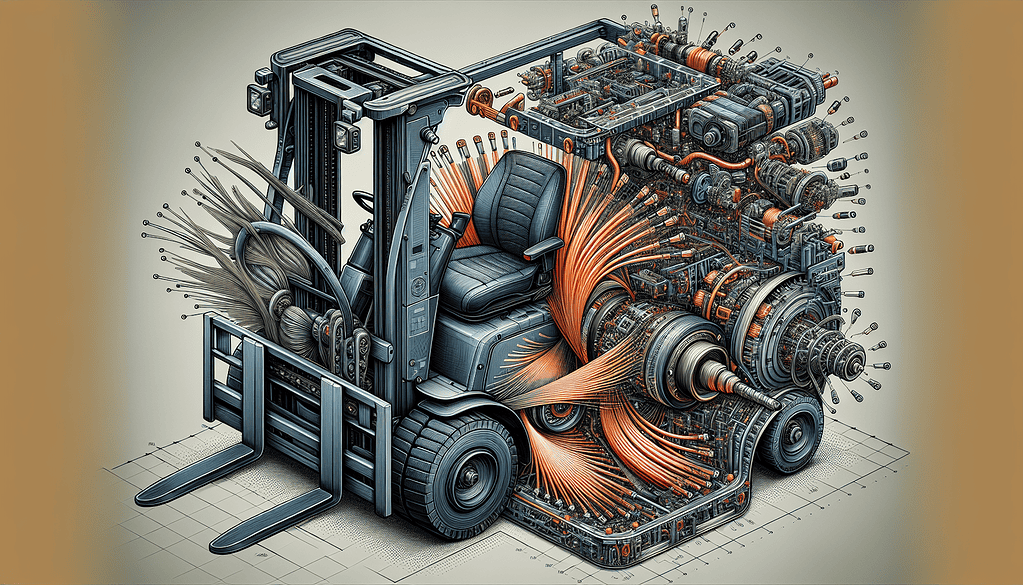

The Power Behind the Machine: Forklift Propulsion

Forklifts equipped with pneumatic tires are well-adapted for harsh terrain; in contrast, those outfitted with cushion tires are optimal for indoor settings and flat surfaces.

Incorporating extendable frames into a forklift boosts its load-bearing potential immensely, enhancing its adaptability in handling various loads.

Reach Trucks

In warehouses, reach trucks are a fundamental tool for order pickers, excelling at accurate pallet retrieval. Characteristic elements of these trucks include:

Forks that can extend past the reach trucks’ bodies and pallets within warehouse racks directly

A design incorporating two external legs to distribute the weight of the load and a solitary set of wheels located at the rear

They are tailored for operation within confined aisle spaces and capable of reaching elevated rack positions, making them an efficient substitute for walkie stackers when handling materials.

Heavy Duty Forklifts

In challenging conditions, it’s the robust forklift that springs into action. This is precisely where heavy-duty forklifts come into play. These machines boast an impressive lift capacity spectrum, starting at 30,000 pounds and reaching a colossal 100,000 pounds, engineered to tackle significant challenges.

Thanks to hydraulic levers equipped with these forklifts, they can effortlessly manage exceptionally heavy loads. Their adeptness makes them perfectly suited for demanding outdoor locations such as construction sites or any setting where lifting heavy items to great heights is essential.

In addition, this forklift is a great match with forklift attachments.

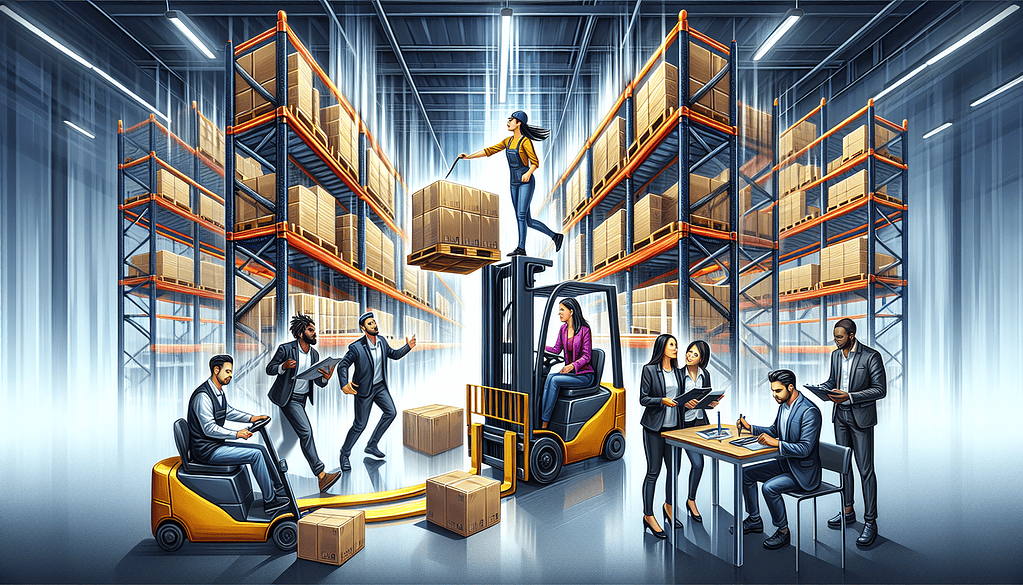

Safety First: Forklift Operator Training & Standards

When operating a forklift truck, prioritizing safety is essential. Untrained operators can cause dangerous accidents, resulting in serious injuries or even death, as well as expensive damages. To avoid such outcomes, employees must take the following steps:

Conduct initial training for forklift truck operators

Offer additional refresher training at least every three years or sooner if there are changes to the operator’s cooperators in workplace incidents involving a forklift.

Adhere strictly to the guidelines set forth by OSHA regarding safe operation practices.

Certification Requirements

Operators of forklifts are obliged to meet certain certification prerequisites that guarantee the safety of their operations. The crucial requirements include:

Being at least 18 years old is mandatory for operators.

Holding a valid official certification, subject to triennial renewal, is essential.

Employers are responsible for ensuring the delivery of thorough training in operating forklifts and adhering strictly to OSHA regulations.

Such training encompasses theoretical instruction and hands-on practice, leading to an evaluation that consists of a written examination and practical skills verification.

Best Practices for Safe Operation

To operate material handling equipment safely, adhere to these crucial measures:

Acquire appropriate certification by undergoing extensive training.

Successfully clear a written examination that tests your understanding of operating a forklift.

Conclude with an on-the-job assessment to solidify your qualifications.

Adherence to this process will certify that you conduct forklift operations with safety and responsibility at the forefront.

Advanced Solutions: Automation in Forklift Technology

In forklift advancements, Automated Guided Vehicles (AGVs) are at the forefront of propelling efficiency and cost savings in material handling. These advanced machines excel at performing monotonous, manual, or dangerous tasks previously carried out by humans.

This shift mitigates damage expenses, bolsters labor productivity, and frees human operators to focus on activities that add more value. Ask your favorite forklift manufacturer about their newest technology.

Automated Lift Trucks

Automation has ushered in a novel class of forklift trucks designed to be at the heart of contemporary warehouse functions, addressing workforce shortages.

These automated machines transform material handling, equipped with remote control operations for improved line-of-sight, embedded telematics to elevate warehouse fleet management intelligence, and sophisticated systems that allow scalability.

The adoption of automation within forklift technology significantly enhances warehousing procedures. This development accelerates supply chain efficiency and delivers potent solutions for material handling challenges.

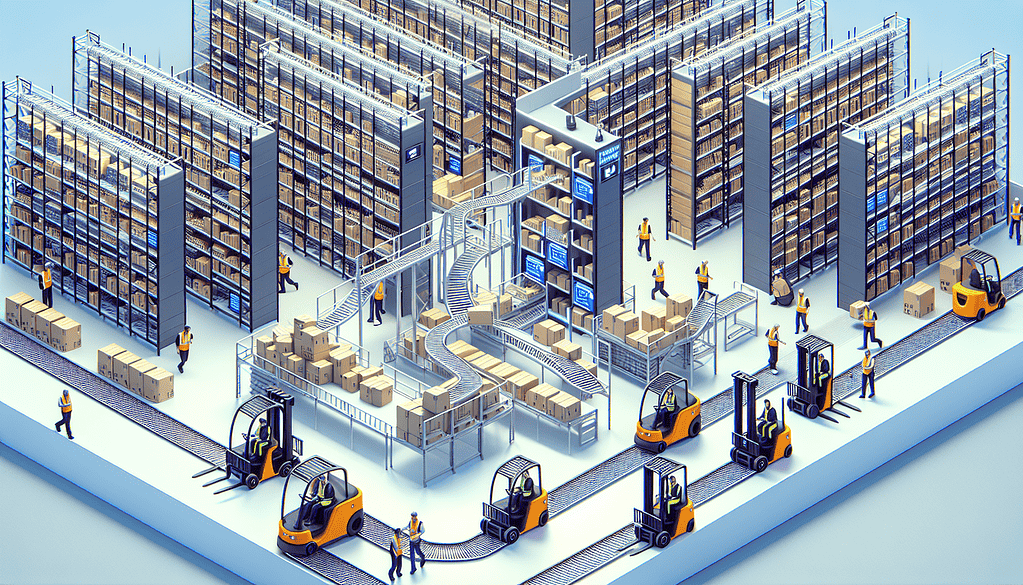

Integration with Warehouse Systems

Their full capabilities become apparent when the automated forklift fleet is harmoniously incorporated into Warehouse Management Systems (WMS).

This synergy improves the precision of inventory management, maximizes warehouse space utilization, and ensures a steady distribution of parts and components.

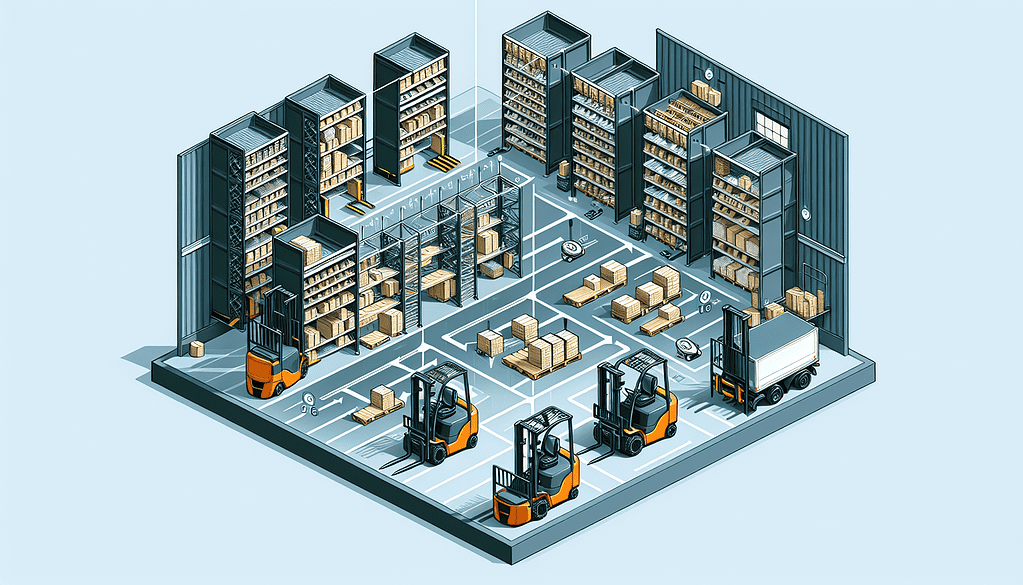

Selecting a Forklift for Your Warehouse Needs

ct partner – it must suit your warehouse demands and improve operational efficiency.

When selecting a forklift, it’s essential to consider how equipment like the pallet truck plays a role in offloading and storing loads in confined spaces. Considerations should encompass:

The size of the warehouse layout

Emissions and noise levels

Types of terrain where it will be operated

The total load capacity needed

When heavy lifting tasks are involved, choose a forklift with a lift capability that surpasses the heaviest loads anticipated to ensure safe and efficient handling.

Assessing Warehouse Layout

The layout of a warehouse is crucial when choosing a forklift. The chosen forklift must effectively leverage its maximum load capacity, with the load positioned centrally, as indicated on the machine’s datasheet.

In particular, aisles in warehouses should be around 13 feet wide to accommodate standard counterbalance forklifts so they can function efficiently.

Lift Truck Load Considerations

Assessing the nature and weight of the materials it is expected to carry is essential for determining a forklift’s suitability.

For example, Toyota offers an extensive selection of forklifts capable of handling loads as light as 3,000 lbs and scaling up to handle hefty weights up to 125,000 lbs. This wide capacity range ensures they can meet various material handling needs.

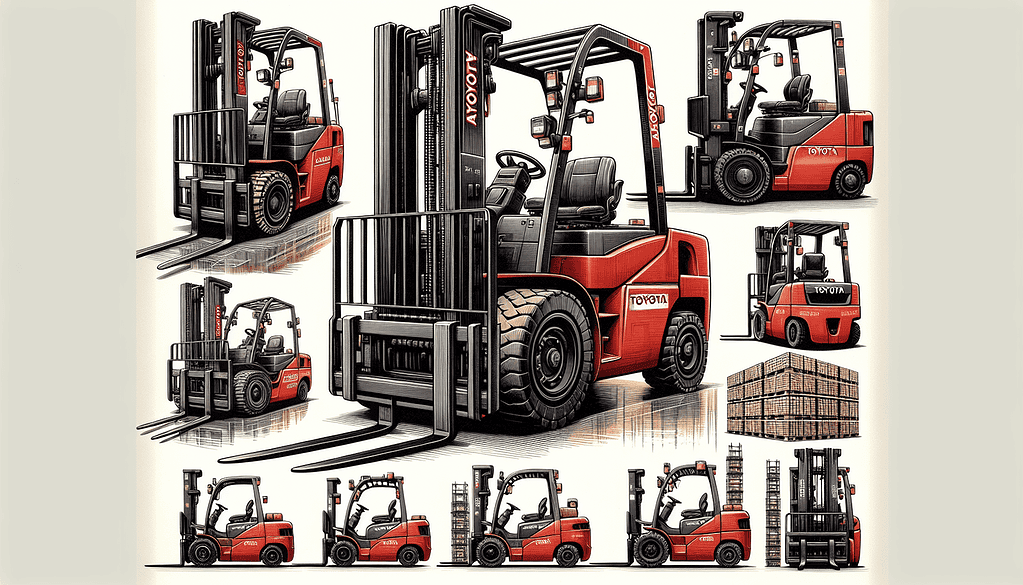

Toyota’s Material Handling Forklift Trucks

Toyota is a top provider of cutting-edge forklifts in the material handling industry. Noteworthy attributes of their forklift offerings include:

An assortment of models tailored to various requirements

A pledge to enduring collaboration via initiatives such as Toyota 360 Support

A focus on the end-user with an emphasis on comfort for the operator and efficiency in operation

Toyota’s Toyota’s excellence and inventive progress have solidified its reputation as a reliable choice among sector professionals.

Toyota Forklifts

Toyota offers a comprehensive selection of forklifts to meet any material handling needs. Toyota provides tailored solutions across multiple sectors, from electric variants designed for indoor use to robust trucks built for demanding tasks.

With operations extending through Asia, Latin America, Oceania, the Middle East, and Africa, Toyota demonstrates its dedication to delivering complete material handling options globally.

Support and Services

Toyota is dedicated to ensuring their customers are completely satisfied, not just with the vehicles they purchase but also with the post-purchase support. The Toyota 360 Support program comes at no extra charge as part of Toyota’s warranty.

Toyota provides customers with comprehensive forklift service across the country. This includes a network of over 220 dealerships and more than 3,500 certified Toyota technicians available nationwide.

Should customers seek even more service and support options, they can choose an improved package, Toyota 360 Support Plus. This premium version offers additional forklift benefits beyond those the standard program provides.

Summary

In the bustling environment of warehouse material handling, forklifts are essential in driving productivity and efficiency forward. The array of available forklifts, including traditional warehouses and automated guided vehicles, can manage diverse tasks by ensuring peak functionality.

These versatile lift truck materials handling equipment adeptly maneuver through narrow aisles and lift heavy loads while synchronizing with other warehouse systems. Current labor shortages and an emphasis on eco-friendly practices shape industry trends, such as forklifts and automation technologies.

Adopting these advanced material handling solutions is significant in preparation for a more effective and environmentally conscious operating era!

Key Takeaways

- Forklift selection should be tailored to specific warehouse layouts and tasks, with considerations for aisle width, load capacity, and operational terrain. Options range from standard forklifts to specialized narrow aisle and heavy forklifts.

- Different forklift propulsion systems (electric or internal combustion engines) and specialized features (reach trucks, pneumatic or cushion tires, extendable frames) enhance operator safety and efficiency. Certification and adherence to OSHA standards are crucial for safe operation.

- Advancements in forklift technology, including automated guided vehicles and integration with warehouse management systems, improve efficiency and address labor shortages, while selection guidance and support services, like Toyota’s, ensure long-term reliability and customer satisfaction.

Frequently Asked Questions

Q: What factors should I consider when selecting a forklift for my warehouse?

In choosing the right forklift for your warehouse, it is crucial to consider elements like the size of your warehouse layout, types of terrain within the facility, and noise and emission levels. You must consider the load capacity (heavy pallets) that aligns with your storage facilities to ensure an optimal match (standard forklift) for your environment.

Q: What are the advantages of using an electric forklift?

Electric forklifts benefit from operating on cleaner energy and producing no direct emissions. Their quieter functionality diminishes noise-related health hazards and improves communication within the workplace. These aspects make electric forklifts particularly beneficial.

Q: What are the certification requirements for forklift operators?

To operate a forklift, order picker, or pallet jack, the operator must be at least 18 years old and possess valid certification that must be renewed every three years. Employers must provide operators with information that is not compliant with OSHA standards.

Q: How can an automated forklift in warehouse operations enhance throughput?

Using automated forklifts in warehouse settings leads to marked advancements by cutting damage costs, boosting labor efficiency, and facilitating cohesive integration with Warehouse Management Systems. This contributes to superior inventory control and more efficient use of space.

Such enhancements can considerably boost productivity within a warehouse while also elevating safety standards.

Q: What support and services does Toyota offer for their forklifts and pallet jack?

The Toyota 360 Support program delivers services, authentic parts, and a warranty forklift warranty access to an extensive network of over 3,500 certified technicians from Toyota across more than 220 dealer locations, ensuring thorough service coverage nationwide.