Warehouse AI Revolution: Powerful Transformations in Logistics 2026

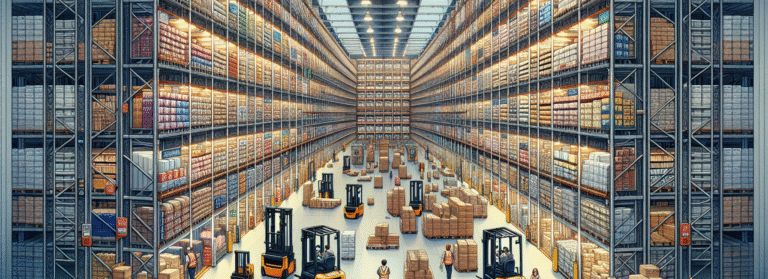

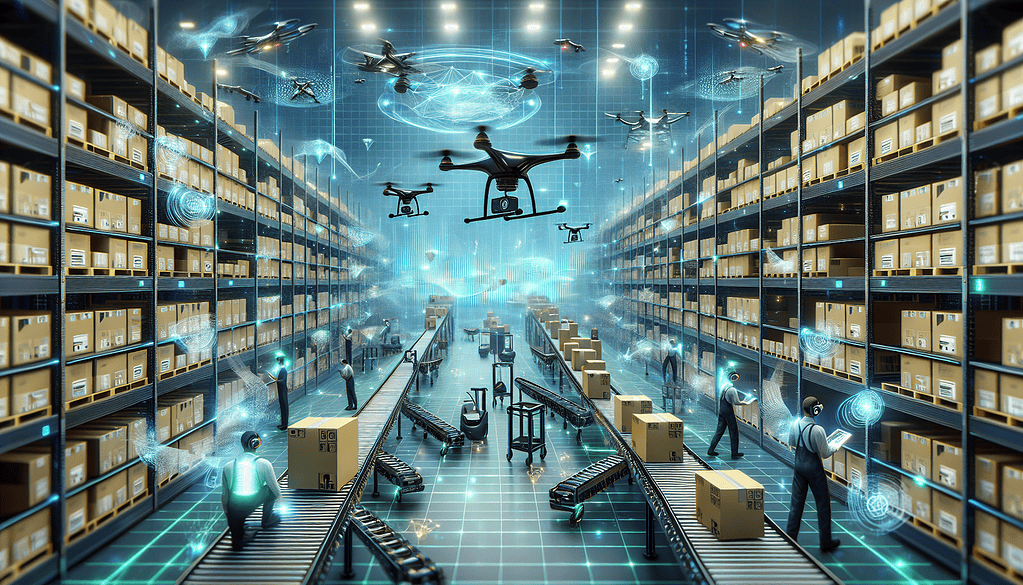

Imagine a warehouse where robots dance in perfect harmony, inventory updates itself, and shipments are predicted before orders are placed. This isn’t science fiction—it’s the AI-powered reality reshaping the warehousing industry today.

It revolutionizes warehouse management by enhancing order fulfillment processes, safety, and predictive maintenance and equipment optimization. Join us as we review the Warehouse AI Revolution.

Introduction

In the fast-paced world of logistics, artificial intelligence (AI) is no longer a futuristic concept but a present-day necessity.

As e-commerce booms and supply chains grow increasingly complex, warehouses are turning to AI to stay competitive, efficient, and ahead of the curve.

From the moment goods enter a facility to the second they’re shipped out, AI is revolutionizing every aspect of warehouse operations.

It’s optimizing inventory levels, streamlining picking processes, and even predicting maintenance needs before breakdowns occur.

This technological leap is not just changing how warehouses function—it’s redefining what’s possible in logistics.

This post will explore how AI transforms warehousing, examining its key applications, benefits, and challenges in this digital revolution.

Whether you’re a warehouse manager looking to modernize operations or a tech enthusiast curious about AI’s real-world applications, buckle up—we’re about to take a journey into the heart of smart warehousing.

Key AI Applications in Warehousing

The integration of AI in warehousing isn’t just a single technology but a suite of intelligent solutions addressing various aspects of operations. Let’s explore the primary areas where AI is making significant impacts:

Inventory Management

AI-powered inventory management systems are revolutionizing how warehouses track and control their stock. These systems use machine learning algorithms to analyze historical data, current stock levels, and incoming orders to maintain optimal inventory levels.

For example, AI can:

Predict when specific items will run low and automatically trigger reorders

Suggest optimal safety stock levels based on demand volatility

Identify slow-moving items and recommend markdown strategies

Optimize product placement within the warehouse for efficient picking

Detect and flag potential inventory discrepancies in real-time

These capabilities reduce carrying costs and minimize the risk of stockouts and overstocking, improving cash flow and customer satisfaction.

Demand Forecasting

AI’s ability to process vast amounts of data makes it exceptionally good at AI-powered demand forecasting. These systems go beyond simple historical analysis, incorporating a wide range of variables such as:

Seasonal trends and cyclical patterns

Economic indicators

Weather forecasts

Social media trends and sentiment analysis

Competitor actions and market dynamics

By considering all these factors, AI can provide highly accurate short-term and long-term demand forecasts. This allows warehouses to prepare for demand spikes, adjust staffing levels, and coordinate with suppliers more effectively.

In some cases, AI-driven demand forecasting has reduced forecast errors by up to 50%, leading to significant improvements in inventory management and customer service.

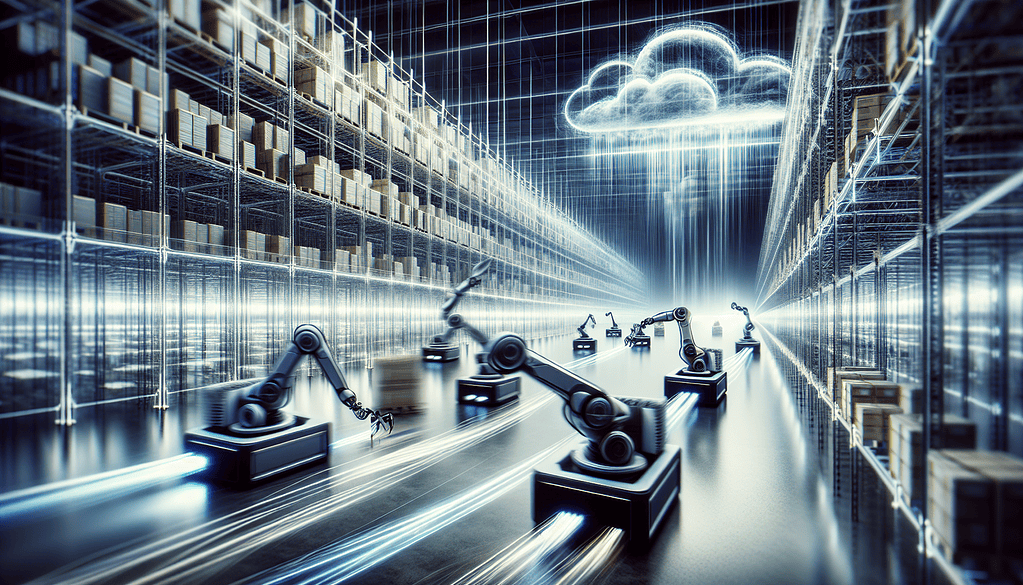

Automated Picking and Packing

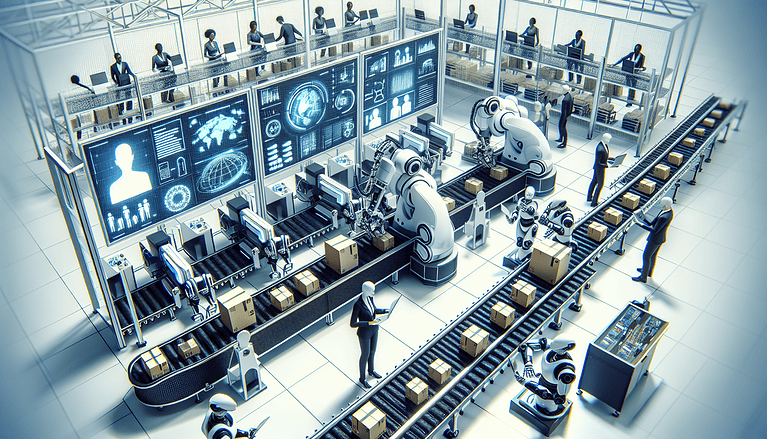

Integrating AI with robotics and automation technologies has significantly improved automated picking and packing systems. These systems typically involve:

Autonomous mobile robots (AMRs) that navigate warehouse aisles

Robotic arms with advanced grippers capable of handling various product types

Computer vision systems for product identification and quality control

AI algorithms for route optimization and task prioritization

Modern AI-powered picking systems can achieve up to 99.9% accuracy while operating several times faster than human pickers. Some advanced systems can adapt to warehouse layout or product assortment changes without requiring manual reprogramming.

Robotic Process Automation (RPA)

RPA powered by AI transforms back-office operations in warehousing. These systems can automate a wide range of tasks, including:

Order processing and validation

Invoice generation and reconciliation

Inventory reconciliation and cycle counting

Shipment tracking and status updates

Report generation and distribution

Supplier performance analysis

The key advantage of AI-driven RPA is its ability to learn and improve over time. For instance, it can identify patterns in order errors, suggest process improvements, or adapt to changes in document formats without human intervention.

By automating these repetitive tasks, warehouses can reduce processing times from hours to minutes, eliminate data entry errors, and free up human staff for more strategic roles. Some companies have reported up to 80% reduced processing times for certain tasks after implementing AI-powered RPA.

These AI applications create a more efficient, accurate, and responsive warehousing ecosystem. As these technologies evolve and become more integrated, we can expect to see even greater transformations in warehouse operations, pushing the boundaries of what’s possible in logistics and supply chain management.

Benefits of AI in Warehouse Operations

The implementation of AI in warehousing brings a multitude of advantages that significantly enhance overall operations. Let’s delve into the key benefits:

Increased Efficiency

AI dramatically boosts warehouse operational efficiency through the following:

Optimized picking routes that reduce travel time

Faster and more accurate inventory counts

Automated sorting and packing processes

Improved space utilization through intelligent storage algorithms

These improvements can lead to 25-50% productivity gains in many warehouses. For instance, AI-powered pick-to-light systems have been shown to increase picking speeds by up to 37% compared to traditional methods.

Cost Reduction

AI helps cut costs across various areas:

Lower labor costs through automation of repetitive tasks

Reduced inventory carrying costs by optimizing stock levels

Decreased energy consumption through smart lighting and climate control

Minimized returns handling costs by improving order accuracy

Some warehouses have reported overall cost reductions of 15-20% after implementing AI solutions. The initial investment in AI technology often pays for itself within 12-18 months.

Error Minimization

AI significantly reduces human errors in various processes:

Near-perfect inventory accuracy through continuous, automated counting

Improved order fulfillment accuracy, often exceeding 99.9%

Reduced data entry errors in paperwork and documentation

Early detection of potential issues before they become critical

By minimizing errors, warehouses can significantly reduce costs associated with returns, reshipping, and customer service issues. One study found that AI-driven quality control reduced shipping errors by 90% in a large e-commerce warehouse.

Enhanced Safety

AI contributes to a safer warehouse environment by:

Predicting and preventing equipment failures before they occur

Optimizing the movement of forklifts and other vehicles to reduce accident risks

Monitoring worker movements and suggesting ergonomic improvements

Automatically detecting and alerting staff to potential safety hazards

These safety enhancements protect workers and reduce workplace accidents and downtime costs. Some warehouses have reported up to a 60% reduction in safety incidents after implementing AI-powered safety systems.

Scalability and Flexibility

AI systems provide warehouses with unprecedented scalability and flexibility:

Easily adapt to changes in demand or product mix

Quickly reconfigure operations for new product lines or seasonal peaks

Scale operations up or down without proportional increases in labor costs

Integrate seamlessly with new technologies and systems as they emerge

This adaptability is particularly valuable in today’s fast-paced, ever-changing market conditions. AI allows warehouses to respond quickly to market shifts, giving them a competitive edge.

Data-Driven Decision Making

AI provides warehouse managers with deep, actionable insights:

Real-time visibility into all aspects of warehouse operations

Predictive analytics for proactive problem-solving

Detailed performance metrics and key performance indicators for continuous improvement

Scenario modeling for strategic planning

These insights enable more informed decision-making, leading to ongoing improvements in efficiency and cost-effectiveness. Many warehouses report that the data-driven insights from AI have been transformative in shaping their long-term strategies.

By leveraging these benefits, warehouses can significantly improve their operations, reduce costs, and enhance their competitive position in the market. As AI technology advances, we can expect these benefits to grow even more pronounced, further cementing AI’s role as a crucial tool in modern warehousing.

Challenges and Considerations for Artificial Intelligence

The use of AI raises several ethical and legal questions:

Ensuring fair and unbiased decision-making by AI systems

Addressing potential job displacement

Compliance with evolving AI regulations

Liability issues in case of AI-related accidents or errors

Warehouses need to stay informed about the legal landscape surrounding AI and consider the broader implications of their AI implementations.

Integration Challenges

Incorporating AI into existing warehouse ecosystems can be complex:

Compatibility issues with legacy systems

Need for standardized data formats and protocols

Challenges in integrating multiple AI solutions

Potential resistance from existing technology vendors

Careful planning and a phased approach to integration can help mitigate these challenges.

Scalability and Flexibility

While AI offers scalability, it also presents challenges:

Ensuring AI systems can adapt to changing business needs

Managing the increasing complexity of AI as it scales

Balancing automation with the need for human oversight

Keeping pace with rapidly evolving AI technologies

Warehouses must choose flexible AI solutions and maintain a long-term perspective on their AI strategy.

By acknowledging and preparing for these challenges, warehouses can smooth their transition to AI-driven operations. While the path may not be without obstacles, the potential benefits of AI in warehousing make it a journey worth undertaking for many organizations.

Supply Chain Management Future Trends

While AI offers numerous benefits to warehousing operations, its implementation is not without challenges. Here are some key considerations warehouses must address when adopting AI technologies:

Implementation Costs

The initial investment in AI can be substantial:

Hardware costs (sensors, robots, servers)

Software licensing and customization

Integration with existing systems

Potential disruption to operations during implementation

While the long-term ROI is often positive, the upfront costs can be a significant barrier, especially for smaller warehouses. Conducting a thorough cost-benefit analysis and considering phased implementation to spread out expenses is crucial.

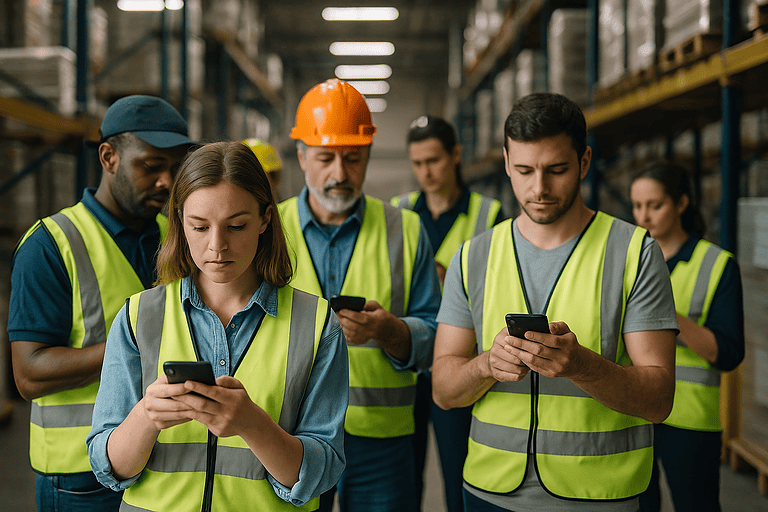

Staff Training and Adaptation

Introducing AI requires a significant shift in workforce skills and roles:

Training employees to work alongside AI systems

Potential resistance to change from staff

Need for new roles (e.g., AI specialists, data analysts)

Possible workforce reduction in some areas

Managing this transition is critical for successful AI adoption. It often requires a comprehensive change management strategy and ongoing training programs.

Data Security and Privacy

AI systems rely on vast amounts of data, raising important security concerns:

Protecting sensitive business and customer data

Ensuring compliance with data protection regulations (e.g., GDPR)

Guarding against potential cyber attacks on AI systems

Managing data sharing with partners and suppliers

Warehouses must invest in robust cybersecurity measures and establish clear data governance policies to address these concerns.

System Reliability and Maintenance

AI systems can be complex and require ongoing attention:

Need for regular software updates and maintenance

Potential for system downtime or errors

Dependency on technology vendors for support

Ensuring system resilience in case of failures

Warehouses must have contingency plans and may need to maintain parallel systems initially to ensure business continuity.

Ethical and Legal Considerations

The field of AI in warehousing is rapidly evolving. Here are some key trends that are likely to shape the future of AI in this sector:

Integration with IoT and Blockchain

The convergence of AI with the Internet of Things (IoT) and blockchain technologies promises to create even smarter, more transparent supply chains:

- IoT sensors will provide real-time data on everything from inventory levels to equipment performance, allowing AI to make even more accurate predictions and decisions.

- Blockchain integration will enhance traceability and security, enabling AI systems to track products from manufacture to delivery with unprecedented accuracy and trust.

- This combination could lead to self-managing inventory systems and autonomous supply chains.

Advanced Predictive Analytics

As AI algorithms become more sophisticated and have access to more data, predictive capabilities will dramatically improve:

- AI can forecast demand with even greater accuracy, potentially down to the individual customer level.

- Predictive maintenance will become more precise, nearly eliminating unexpected equipment breakdowns.

- Advanced risk assessment models will help warehouses prepare for and mitigate potential disruptions.

Autonomous Mobile Robots (AMRs)

The next generation of warehouse robots will be more autonomous and versatile:

- AMRs will use advanced AI to navigate complex, dynamic environments without the need for predefined paths.

- Collaborative robots (cobots) will work alongside humans more seamlessly, adapting their behavior based on the situation.

- Swarm robotics concepts may be applied, allowing large groups of simple robots to perform complex tasks collectively.

Natural Language Processing (NLP) and Voice Control

Voice-activated AI assistants will become more common in warehouse settings:

- Workers can query inventory systems, report issues, or receive instructions hands-free.

- NLP will enable more natural human-AI interaction, making the technology accessible to all staff.

Edge Computing and 5G

These technologies will enable faster, more localized AI processing:

- Edge computing will allow AI decisions to be made closer to the point of action, reducing latency.

- 5G networks will provide the bandwidth for real-time data processing and communication between AI systems.

Augmented Reality (AR) Integration

AR combined with AI will enhance various warehouse processes:

- Picking and packing efficiency will improve with AR glasses providing AI-generated instructions.

- Maintenance and repair processes will be streamlined with AR overlays guided by AI diagnostics.

Emotional AI and Human-AI Collaboration

As AI becomes more advanced, it may start to recognize and respond to human emotions:

- AI systems could adapt their communication style based on a worker’s stress level or mood.

- This could lead to more effective human-AI teams and improved job satisfaction.

Sustainability Focus

AI will play a crucial role in making warehouses more environmentally friendly:

- AI-optimized routes and packing will reduce fuel consumption and packaging waste.

- Energy usage will be optimized through AI-controlled lighting and climate systems.

- AI will help implement and manage circular economy principles in warehousing.

Quantum Computing

While still in the early stages, quantum computing could revolutionize AI capabilities in warehousing:

- Complex optimization problems could be solved exponentially faster.

- This could lead to breakthroughs in route planning, inventory optimization, and demand forecasting.

As these trends develop, we can expect warehouses to transform into highly automated, intelligent, more efficient, responsive, and sustainable systems. The key for businesses will be to stay informed about these developments and be prepared to adopt new technologies as they mature.

Case Studies

To illustrate the real-world impact of AI in warehousing, let’s examine a few success stories of AI implementation:

Amazon’s AI-Powered Fulfillment Centers

Amazon has been at the forefront of AI adoption in warehousing. Their implementation showcases multiple AI applications:

Kiva robots: These autonomous mobile robots move entire shelves of products to human pickers, dramatically reducing walking time and increasing efficiency.

Predictive demand planning: AI algorithms analyze vast amounts of data to predict customer demand, allowing Amazon to position inventory strategically.

Automated packaging: AI-driven systems determine the optimal box size for each order, reducing waste and shipping costs.

Amazon reported a 20% reduction in operating costs and a significant improvement in order fulfillment speed.

DHL’s AI-Enhanced Vision Picking

DHL implemented an AI-powered augmented reality system for order picking:

Workers wear smart glasses that display picking instructions in their field of vision.

AI algorithms optimize picking routes and provide real-time guidance.

The system can adapt to different languages and user preferences.

Results: DHL saw a 15% increase in productivity and significantly reduced error rates. The system also reduced training time for new employees by 50%.

Ocado’s AI-Driven Automated Warehouse

UK-based online grocer Ocado built a highly automated warehouse using AI and robotics:

A grid system of robots, coordinated by AI, moves and retrieves products.

Machine learning algorithms optimize the placement of goods and predict maintenance needs.

AI is used for demand forecasting and reducing food waste.

Results: Ocado can process a 50-item order in under five minutes, a fraction of the time in traditional warehouses. They’ve also seen significant improvements in inventory accuracy and reduced waste.

Nike’s AI Inventory Management

Nike implemented an AI system to optimize inventory across its global network of stores and warehouses:

The system uses machine learning to predict demand at a local level.

It can automatically reallocate inventory between locations based on predicted demand.

AI also helps identify slow-moving inventory for markdown.

Results: Nike reported a 30% reduction in inventory levels while maintaining or improving product availability. This led to significant cost savings and improved cash flow.

XPO Logistics’ AI-Powered Labor Planning

XPO Logistics uses AI for workforce management in its warehouses:

The system predicts labor needs based on incoming orders and historical data.

It can suggest optimal staff schedules and task assignments.

AI also provides productivity insights and identifies training needs.

Results: XPO saw a 5-7% improvement in labor efficiency and significantly reduced overtime costs. More consistent schedules also improved employee satisfaction.

These case studies demonstrate the tangible benefits that AI can bring to warehouse operations in various aspects—from inventory management and order fulfillment to labor planning and cost reduction. They also highlight how AI can be adapted to different warehousing operations, from e-commerce giants to traditional retailers and third-party logistics providers.

While the specific results may vary, these examples show that, with proper implementation, AI can significantly improve efficiency, accuracy, and cost-effectiveness in warehousing operations.

Conclusion

As we’ve explored throughout this post, AI is not just transforming warehousing—it’s redefining what’s possible in logistics and supply chain management.

AI touches every aspect of warehouse operations, from inventory optimization to robotic automation, from demand forecasting to process streamlining.

The benefits are clear and compelling:

Dramatically increased efficiency and productivity

Significant cost reductions across various operations

Minimized errors and improved accuracy

Enhanced safety for warehouse workers

Improved scalability and adaptability to market changes

Data-driven decision-making for continuous improvement

However, the journey to AI implementation is not without its challenges. Warehouses must navigate issues such as:

Substantial initial investment costs

The need for staff training and change management

Data security and privacy concerns

System integration and maintenance complexities

Despite these challenges, the case studies we’ve examined demonstrate that the benefits of AI in warehousing far outweigh the hurdles. Companies that have successfully implemented AI solutions are seeing remarkable improvements in their operations, gaining a significant competitive edge in the process.

Looking to the future, the potential of AI in warehousing seems boundless. As we see further integration with technologies like IoT, blockchain, and augmented reality, and as we witness advancements in areas like autonomous mobile robots and quantum computing, the capabilities of AI-driven warehouses will only continue to expand.

The message for logistics and supply chain businesses is clear: AI is not just a futuristic concept but a present-day reality rapidly becoming a necessity. Those who embrace this technology now will be well-positioned to lead in the increasingly competitive and complex world of modern logistics.

The AI revolution in warehousing is here. The question is no longer whether to adopt AI but how quickly and effectively you can integrate it into your operations. As we’ve seen, the potential rewards are substantial. The future of warehousing is intelligent, automated, and data-driven – and that future is now.

This concludes our comprehensive look at AI in warehousing. By embracing these technologies, warehouses can transform from mere storage facilities into strategic assets that drive business growth and customer satisfaction.