Mezzanine Vendors: How to Choose the Right Partner for Your Warehouse

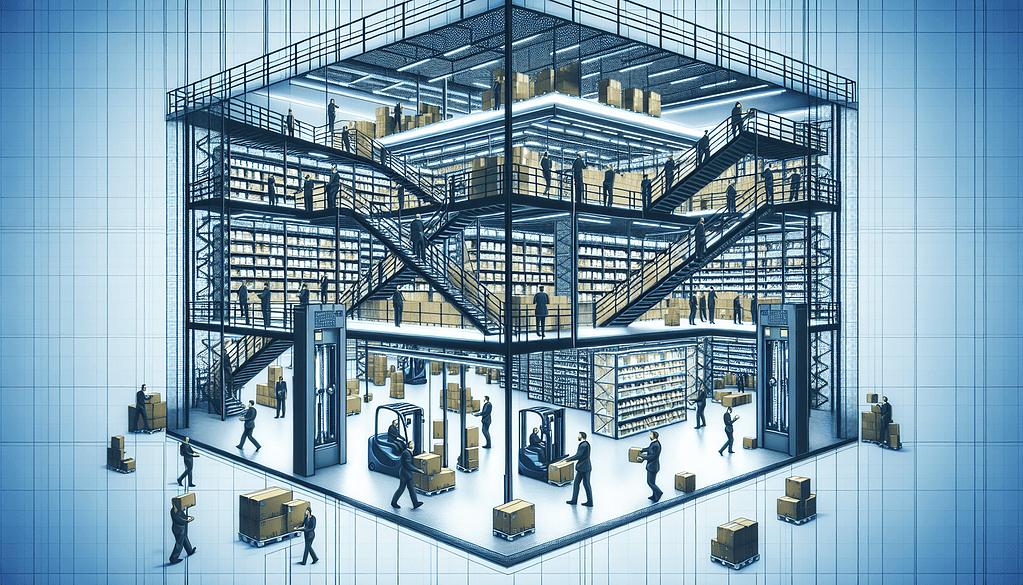

Mezzanine vendors play a critical role in helping warehouses expand their space without costly new construction. A mezzanine is one of the most effective ways to add usable square footage inside your existing facility, but selecting the right partner ensures safety, compliance, and long-term ROI.

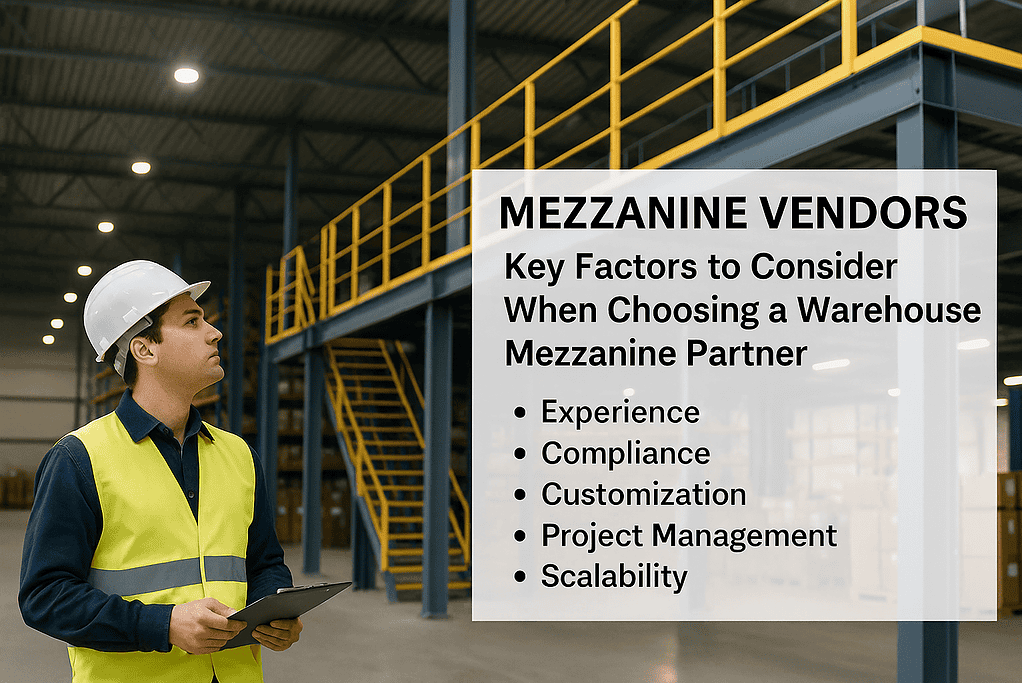

What to Look for in a Mezzanine Vendor

When evaluating mezzanine vendors, keep these factors in mind:

Experience & Track Record – Vendors with proven installations in warehouses similar to yours will understand permitting, safety, and design requirements.

Engineering & Compliance – Your mezzanine must meet OSHA and International Building Code (IBC) standards, particularly in terms of load capacity, egress, and safety railings.

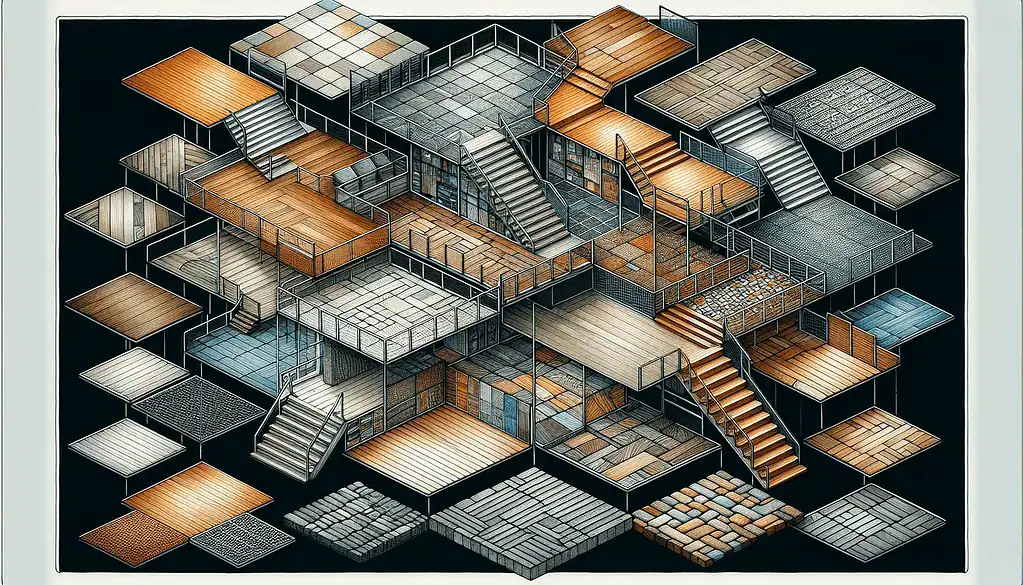

Customization Options – Look for flexibility in materials (structural steel, rack-supported, or free-standing), heights, decking, and integration with existing systems.

Project Management Support – The best vendors don’t just deliver steel; they handle design, permits, installation, and post-installation support.

Lead Times & Scalability – Warehouses often expand in phases. Ensure your mezzanine vendor can scale with your business.

Types of Mezzanine Vendors

Manufacturers – Companies that design and build their own mezzanines (e.g., Wildeck, Panel Built).

Distributors & Integrators – Offer mezzanines from multiple manufacturers, plus installation services (often through local partners).

Regional Vendors – Local fabricators or resellers can offer quick turnaround and support, but may have limited catalogs.

Cost Factors to Compare

While every mezzanine project is unique, cost typically depends on:

Steel prices & materials

Square footage and load capacity

Safety features (stairs, gates, handrails, kickplates)

Installation labor vs. in-house assembly

Future flexibility – Can the mezzanine be expanded later?

Always request detailed quotes that include both installation and freight costs.

Examples of Industry-Recognized Mezzanine Vendors

Here are a few well-known suppliers often used in warehouse projects:

Wildeck – Known for custom-engineered mezzanines and safety equipment.

Panel Built – Offers modular and structural steel mezzanines.

Cogan – North American supplier with broad product options.

Cubic Designs (Steel King Industries) – Strong track record with distribution centers.

(Note: Warehouse Whisper does not endorse specific vendors; these are listed for research purposes.)

Checklist Before Selecting a Vendor

✅ Complete a site survey and confirm load requirements

✅ Request engineered, stamped drawings

✅ Verify compliance with OSHA and IBC

✅ Compare installation lead times and warranties

✅ Check references from previous warehouse customers

Conclusion

A mezzanine can transform your warehouse by doubling floor space without expanding your footprint. But choosing the wrong mezzanine vendor can lead to costly delays, safety risks, and compliance headaches. By focusing on experience, compliance, and long-term support, you can select the right partner to maximize your investment.