How to Optimize Warehouse Location Sizing for Maximum Efficiency

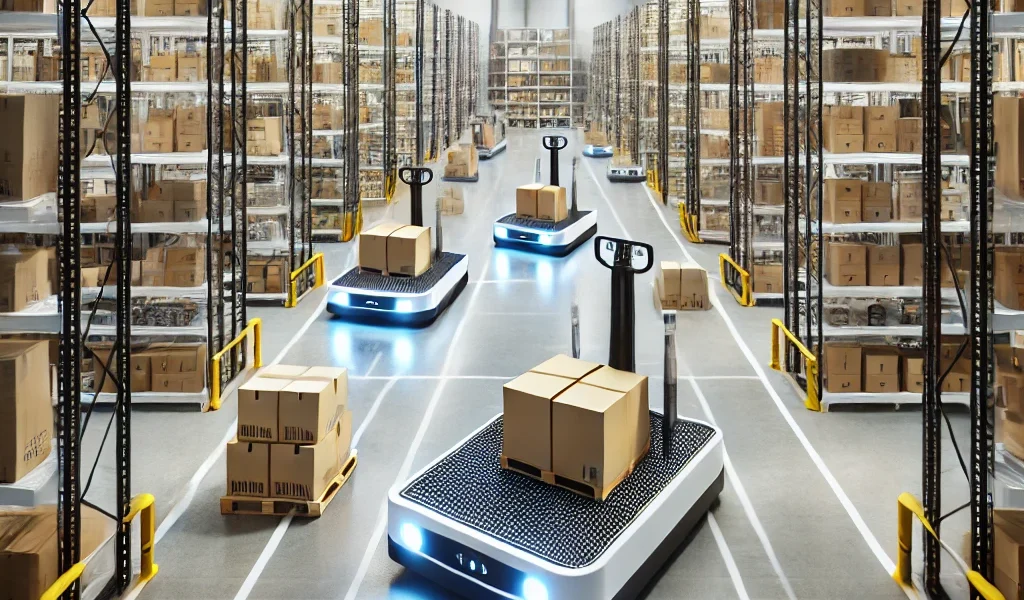

Designing an efficient warehouse starts with one critical factor: accurate warehouse location sizing. Whether you’re expanding your ecommerce fulfillment capabilities or building a new warehouse from scratch, planning your space with precision ensures optimal operations, inventory flow, and scalability.

But how do you design for the future when you only have current product data? The answer isn’t always straightforward—and that’s exactly what we’ll explore here.

Why Warehouse Location Sizing Matters

Effective warehouse location sizing is about more than just fitting products on shelves. It’s about:

Maximizing storage density

Enhancing pick-and-pack efficiency

Supporting scalable operations

Reducing travel time within pick paths

Accommodating product size and velocity variations

For e-commerce businesses, where SKU counts are high and inventory turnover is rapid, your location types and sizing strategy can significantly impact warehouse productivity.

Start with the Basics: Understand Product Dimensions and Velocity

Before diving into warehouse layout optimization, you need a firm grasp on your product dimensions and cubic velocity (the volume of each SKU multiplied by its movement rate). Designing around current metrics may suffice for some, but if you’re scaling, projected SKU growth and seasonal volume fluctuations must be factored into your planning.

A few key rules to follow:

Allocate space based on both current and projected product movement.

Match the location sizes to the product dimensions for optimal storage efficiency.

Ensure redundancy across zones—so if one zone is overwhelmed, picking can shift seamlessly to another.

Location Types: What You Need and When to Use Them

1. Bulk Storage: For Oversized or Heavy Inventory

Bulk storage is essential for large, heavy, or non-standard items that can’t be racked conventionally.

Use bulk storage for:

Knock-down (KD) furniture, TVs, appliances

Pallets exceeding weight limits of selective racks (e.g., bottled liquids)

High-cube or irregular-shaped promotional SKUs

Products that ship as single-item orders

Advantages:

Handles heavy-duty inventory

Utilizes vertical space with tall, reinforced structures

Keeps warehouse organized and navigable

Easily integrates with pallet tracking systems

✅ Pro Tip: Plan bulk areas near outbound zones to streamline fulfillment for large items.

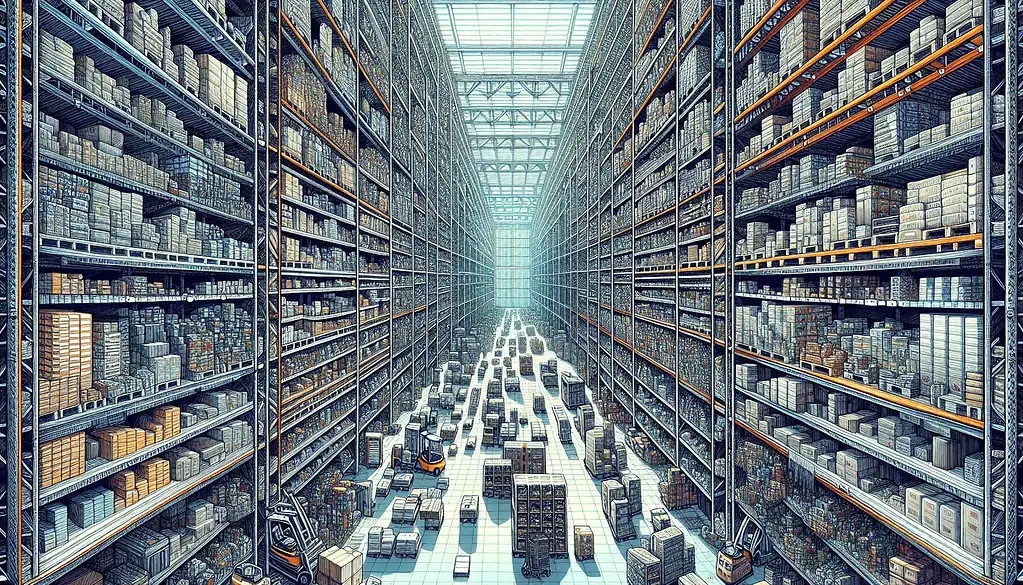

2. Pallet Rack Systems: Backbone of High-Density Storage

If your warehouse handles large quantities of palletized inventory, choosing the right pallet racking system is critical.

Popular Pallet Rack Types:

Selective Pallet Racking – Best for frequently accessed items. Easy to manage stock rotation (FIFO/LIFO).

Push-Back Racking – Ideal for medium-velocity SKUs. Maximizes space with a last-in, first-out system.

Drive-In Racking – High-density but low-accessibility. Useful for storing uniform, bulk inventory with low pick frequency.

When to Use Rack Storage:

Boxed items

Bagged goods like grains or pet food

Odd-shaped items that don’t stack well on pallets

Factors to Consider:

Weight capacity: Match rack load ratings to the heaviest SKU.

Accessibility needs: More accessibility usually means more aisles (less density).

Ventilation and visibility: Consider mesh or wire shelves for perishable or visible inventory.

3. Shelving Units: Flexibility for Small or Fast-Moving Items

Smaller SKUs or fast-pick inventory call for agile, shelf-based storage solutions.

Great for:

Spare parts

Tools or accessories

E-commerce orders with frequent single-line picks

Wire Shelving: Lightweight, ventilated—ideal for dry goods or light inventory.

Metal Shelving: Strong, durable, and long-lasting—used in most general-purpose applications.

Plastic Shelving: Rust-resistant and affordable—best for low-weight, low-humidity environments.

Key Takeaways for Warehouse Space Planning

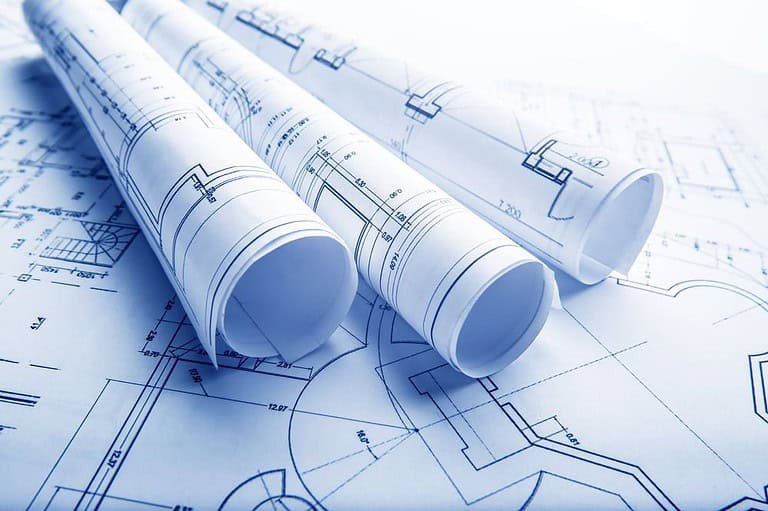

Designing a future-ready warehouse requires a mix of data-driven planning, flexible infrastructure, and scalable storage systems. Here’s what you need to remember:

Don’t rely solely on today’s product specs—plan for SKU and velocity changes.

Include redundant zones with similar location types to support pick path optimization.

Choose rack and shelf systems based on product weight, volume, and movement patterns.

Use bulk storage zones for oversized or high-velocity promotional items.

Focus on accessibility and modularity in your shelving systems to stay agile.

Final Thought: Design With Growth in Mind

The most successful warehouse layout designs aren’t just functional today—they’re built to evolve. Whether you’re outfitting your first facility or upgrading for 3PL services, proper warehouse location sizing lays the groundwork for long-term success.