AI Powered Inventory Forecasting: Smarter Stock, Lower Costs

Running a warehouse without accurate demand planning often leads to the same costly problems: overstocking, stockouts, and wasted capital. Traditional forecasting methods, built on spreadsheets and static reports, can’t keep up with today’s volatile supply chains. That’s where AI powered inventory forecasting comes in.

By applying machine learning and real-time data analysis, warehouses can predict demand with significantly greater accuracy, adjust to market shifts instantly, and maintain the optimal amount of stock on hand.

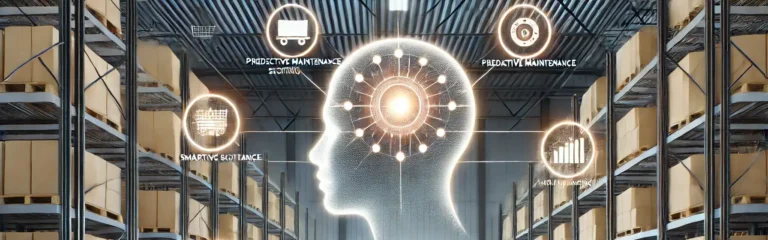

What Is AI-Powered Inventory Forecasting?

AI-powered inventory forecasting utilizes machine learning algorithms and data-driven models to predict future demand, stock requirements, and replenishment needs.

Instead of static forecasts, AI models:

- Process real-time data (sales, supplier lead times, market signals).

- Identify patterns invisible to manual methods.

- Continuously learn and improve accuracy over time.

Why Traditional Forecasting Falls Short

- Static models: Can’t adapt to sudden market changes.

- Human error: Spreadsheets and manual data entry lead to mistakes.

- Lagging insights: Data is often outdated by the time reports are reviewed.

- Blind spots: Fails to capture seasonality, promotions, or supply chain disruptions.

Benefits of AI-Powered Inventory Forecasting

1. Reduced Stockouts & Lost Sales

AI models can flag items that are likely to run out before it happens, ensuring replenishment orders are placed on time.

2. Lower Carrying Costs

Overstock ties up capital. AI helps maintain lean safety stock without risking shortages.

3. Smarter Seasonal Planning

Machine learning identifies trends tied to holidays, weather, or promotions, automatically adjusting forecasts.

4. Real-Time Adaptability

When supply chain disruptions hit (delayed shipments, supplier shortages), AI systems reforecast instantly.

5. Better Supplier Negotiations

Data-driven forecasts strengthen your hand when negotiating lead times and contracts.

Key Technologies Behind It

- Machine Learning (ML) → Algorithms learn from past sales, trends, and external factors.

- Natural Language Processing (NLP) → Helps interpret unstructured data like news or market reports.

- IoT Sensors & RFID → Provide real-time stock visibility.

- Cloud Integration → AI tools plug directly into WMS and ERP systems.

Real-World Use Cases

- E-commerce retailers: Predicting SKU demand spikes during holiday sales.

- Pharma: Adjusting forecasts for flu season vaccine demand.

- Food distributors: Managing perishable stock with AI-driven shelf-life tracking.

- 3PLs: Using AI to balance client inventory across multiple warehouses.

Challenges in Adoption

- Data quality issues: Bad inputs lead to inaccurate forecasts.

- Change management: Staff need training to trust AI recommendations.

- Integration costs: Linking AI to legacy WMS/ERP systems takes planning.

Best Practices to Get Started

- Clean your data — accurate historical data is the foundation.

- Start small — pilot AI forecasting on a single SKU family.

- Integrate with WMS — connect forecasts directly to execution.

- Monitor & adjust — use dashboards to refine models.

- Train your people — ensure operators know how to interpret AI output.

Future of AI Powered Inventory Forecasting

- Self-learning supply chains: End-to-end forecasting from suppliers to the last mile.

- Digital twins: Simulating entire networks with AI-driven demand signals.

- AI + blockchain: Trustworthy, transparent demand data sharing.

Conclusion

AI-powered inventory forecasting helps warehouses move beyond guesswork to precision. By reducing stockouts, cutting carrying costs, and adapting to real-world disruptions, AI provides a competitive advantage in a volatile market.

Companies that invest today in AI-driven forecasting will lead tomorrow’s supply chains with smarter stock, happier customers, and stronger margins.

Additional Resources

Gartner (Supply Chain Forecasting with AI): According to Gartner’s research, companies adopting AI-driven forecasting can reduce inventory errors by up to 30%.

McKinsey (AI in Supply Chain): McKinsey reports that AI-powered forecasting can unlock billions in value by aligning inventory with real-time demand signals.

Deloitte (AI Adoption Challenges): Deloitte notes that poor data quality and resistance to change are among the biggest hurdles companies face when implementing AI in supply chain forecasting.

Walmart / Amazon AI Forecasting Case Study: Retail leaders like Walmart and Amazon are already utilizing AI-powered demand forecasting to enhance on-shelf availability and reduce waste across their networks.