Exploring Warehousing: Strategies for Efficient Storage 2026

What makes a warehouse more than a storage space? It’s a critical point in the supply chain. Warehousing optimized for efficiency fuels business success by streamlining product delivery.

This article cuts through the complexity of warehousing. It details the strategies and systems that make it important. It covers leveraging Warehouse Management Systems (WMS) and optimizing logistics for e-commerce.

Warehousing industry experiences rapid expansion. Technology is advancing fast. E-commerce businesses and the need for more storage are driving this growth. It’s revolutionizing logistics, supply chain management, and inventory control.

Key Takeaways

- Warehousing is a critical element of logistics management. It involves complex tasks, including managing inventory, fulfillment, and asset protection. These tasks rely on technologies like a Warehouse Management System (WMS). It gives better visibility and efficiency.

- Although related, storage and warehousing are different. Warehousing involves optimized processes for managing and distributing inventory. In contrast, storage, or using a storage facility, is mainly about securing goods.

Strategic warehousing solutions are essential for modern business needs. They allow companies to:

Use cost-effective storage.

Optimize supply chains.

Increase customer satisfaction by fulfilling orders efficiently.

Integrate warehousing with e-commerce.

Understanding the Essentials of Warehousing

The warehousing function extends beyond the mere storage of products. It’s a key part of supply chain operations. It is the key point. Here, orders get filled and inventory is watched. Resources are protected from surprises.

These facilities can vary greatly in size and complexity. They range from modest stock rooms to large distribution centers. The latter has environmental regulation features and advanced shelving. These shelves ensure precise product tracking.

In this environment, there are many activities. People carefully handle and watch goods move. They use a strategy to maximize efficiency. They store goods in the warehouse. And they get them when needed.

Storing inventory is crucial here. It’s important for efficiently shipping items in the supply chain. It also provides storage spots for products in an e-commerce warehouse. And it integrates with warehouse systems to track and optimize inventory and shipping.

The Role of a Warehouse Management System (WMS)

Enter the WMS, a revolutionary software that turns chaos into order. With a good WMS, you can:

Gain visibility into every warehouse action in real-time.

Bolster productivity while minimizing resources.

Slice storage costs.

Maintain supply chain efficiency.

Offer real-time inventory visibility.

Such systems are indispensable for improving warehouse operations and maximizing efficiency.

They’re not about managing inventory. They’re about scaling a business. They’re about adapting to every property. And they’re about storing unlimited SKUs without a problem.

Distinguishing Between Storage and Warehousing

It’s important to distinguish between mere storage and the broader warehousing concept. Warehousing includes many activities beyond providing space. It involves optimized management in an inventory warehouse.

Simple warehouses are for holding goods. In contrast, distribution centers add more activities like picking, packing, and dispatching items.

Distribution centers are designed for efficiency, unlike conventional warehouses. They focus on quick inventory movement and effective distribution.

These hubs are great at serving other businesses. They handle consumer orders with precision and deliver on schedule.

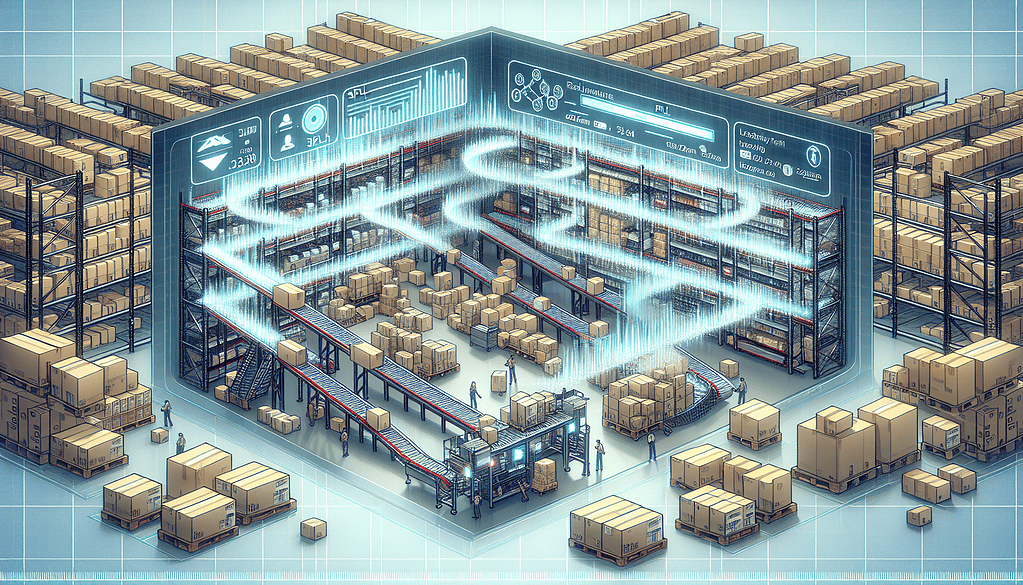

The backbone of the supply chain: warehouse ops

Efficient warehousing is key to supply chain management. It ensures smooth movement and accurate inventory tracking.

Warehouse operations play a key role. But, they are often overlooked. They are part of the pulsating supply chain.

These functions are where meticulous attention to detail and operational efficiency converge. They combine inventory control, order processing, and safeguarding assets into a single stream. This stream moves items through the supply chain management process.

This is also where workforce empowerment comes from two things. They are thoroughly trained and make good decisions.

The warehousing duties cover all stages of handling merchandise. They go from incoming goods to outbound shipments. They ensure accurate store inventory levels and help keep products flowing.

Inventory Management

In the warehousing sector, maintaining control is not merely advantageous. It is imperative. A WMS provides you with capabilities to:

Monitor inventory levels as they change in real-time

Get notified when inventory runs low

Ensure timely availability of necessary stock

Prevent the pitfalls of both overstocking and understocking via automated reorder prompts

Warehouses organize their merchandising to its demand rate. They use techniques like ABC analysis. This optimizes their use of space and resources. It reduces the extensive needs for transportation management.

An efficient order fulfillment process is fundamental to the success of operations. Essential tactics for enhancing this include:

Employing advanced picking methods like wave picking

Fine-tuning pick routes for optimal efficiency

Adopting tailored packaging solutions and employing proven shipping methodologies

These approaches allow staff to process several orders simultaneously. They also ensure items are delivered to customers undamaged. This leads to high customer satisfaction.

Integrating technology into warehousing.

The last component that completes the warehousing ensemble is technology. Imagine advanced systems such as:

Pick to Light and RFID direct employees accurately to specific stock-keeping units.

Automated storage and retrieval mechanisms that eradicate errors in picking.

Better security comes from cameras and strong locks. They help to stop loss.

Using these tools can greatly improve efficiency and safety in a warehouse.

Scanners and RFID verify each item’s correctness. They also track inventory well.

Warehousing’s Impact on E-commerce Businesses.

As e-commerce enterprises expand, effective warehousing becomes paramount. This is where we store merchandise. We’ve processed orders, organized dispatches, and placed each SKU.

E-commerce giants and start-ups face a choice. They must choose between private warehousing and third-party logistics. Third-party services offer customized help with stocking goods and handling shipping.

Efficient warehousing streamlines inventory management. It does not back up e-commerce. It accelerates them.

They optimize inventory management and cut transit times and freight charges. Proficient storage goes beyond supporting and driving its success.

Managing e-commerce inventory.

E-commerce is fast-paced. It involves handling goods that change hands often. This requires exceptional precision. The key to online retail is its fast fulfillment. This requires careful monitoring of stock levels on many sales platforms.

A good WMS offers instant data and tools. They’re needed for operations to keep up with the fast e-commerce industry.

Optimizing Shipping and Handling

In e-commerce, handling can determine success or failure. Integrating advanced technology with a well-managed warehouse makes managing shipments easier. It helps with everything from making labels to choosing cheaper delivery options.

Good picking and packing practices make dispatch faster. They also lower costs and improve customer experiences.

Strategic Warehousing Solutions for Modern Needs

Enterprises today need tailored storage solutions that match their unique needs.

It involves finding ways to cut costs and meet customer demand. It also involves expanding the business. An appropriate warehouse is key to its success.

Businesses need to think about the sensitivity of their products. They should outline key criteria to third-party service providers. This is when they choose a warehouse ally to handle their needs well.

Choosing the right warehouse facility

Choosing the right facility is pivotal. It impacts logistics. A well-situated warehouse improves delivery speeds and reduces transportation expenses.

Being near key roads and the ability to grow is very important in this decision.

Warehouse selection for raw materials depends on various decisive factors. These include local labor dynamics, taxes, financial incentives, and area-specific regulations.

Cost-effective storage solutions

Storage warehouses seek cheap storage solutions. They always seek innovations to make their facilities more efficient.

They use various strategies. They maximize space using small bins and totes. They also combine shipments to cut warehousing costs without damaging the goods.

Conducting routine operations assessments is crucial, too. These audits are vital. They find and fix inefficiencies. These problems can raise the cost of storing items.

Customized Warehousing Services

Businesses with unique storage requirements can find solutions through tailored warehousing services.

These options have specific specialties. They meet the varied demands of different products and sectors. They offer climate-controlled spaces, bonded warehouses, and third-party logistics expertise.

They deliver many services. These include kitting, assembly, cross-docking, and refrigeration. These services ensure that businesses have the adaptability and productivity needed for success.

Logistics Management

Optimized logistics management hinges on the skill of warehouse logistics. Handling inventory well is critical. It reduces distribution expenses and keeps customers happy. This turns operations from basic to tactical.

Positioning warehouses strategically can dramatically reduce transportation expenses. Establishing them in proximity is key to streamlined shipments.

The warehousing site occupies a strategic midpoint. It’s near consumers. This location is crucial for cutting delivery times and costs.

Improvements in warehouse structure help. Techniques like cross-docking are coupled with their use. These changes reduce the costs of long storage periods.

Customer satisfaction with its efficient order fulfillment.

The link between customer satisfaction and efficient order fulfillment is undeniable. Consumers now expect same-day delivery. So, it’s quick order processing and shipping are crucial.

Good warehouse management is key. It reduces inventory mishandling and shipping errors, guaranteeing timely product delivery to customers.

Leveraging Warehousing in Retail and E-commerce

The warehousing sector is crucial in scaling retail stores and e-commerce enterprises. As these businesses expand, warehouses must improve. They must fit the logistical needs of retail and online commerce. This will enhance warehouse operations.

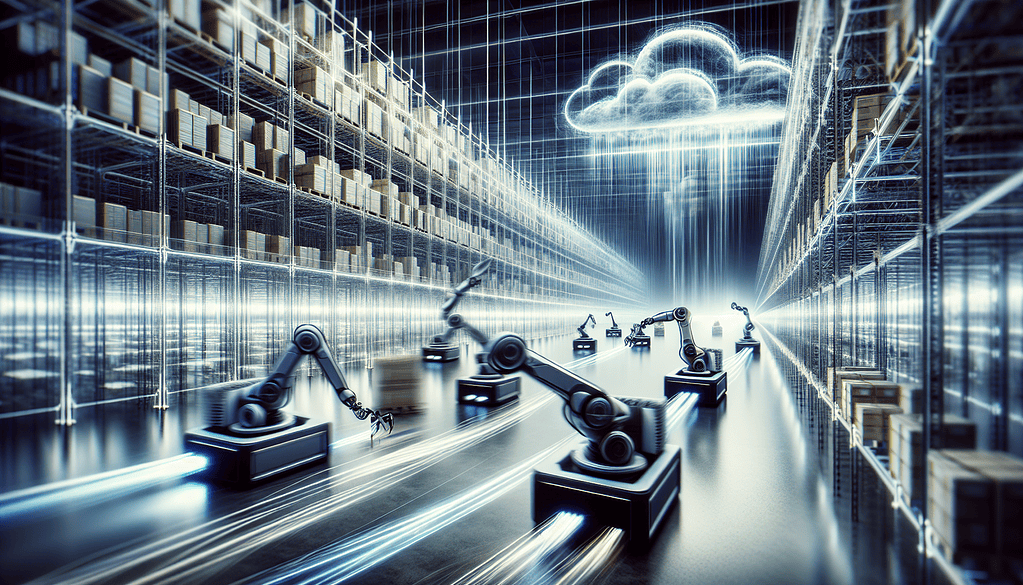

Technological advancements and increased automation are revolutionizing conventional warehousing practices. This innovation lets retailers and e-commerce firms grow their operations. They’ve achieved precision with optimized performance.

From traditional warehousing to modern solutions.

Abandoning traditional approaches to modern techniques has brought profound changes. Technology and automation have overhauled logistics. They’ve boosted efficiency, simplifying inventory and order fulfillment within the warehouse.

Incorporating warehousing into e-commerce businesses.

Integrating warehousing with a comprehensive e-commerce framework is crucial for seamless functionality. Coordinating online shops and warehouse infrastructure is key to maintaining inventory accuracy.

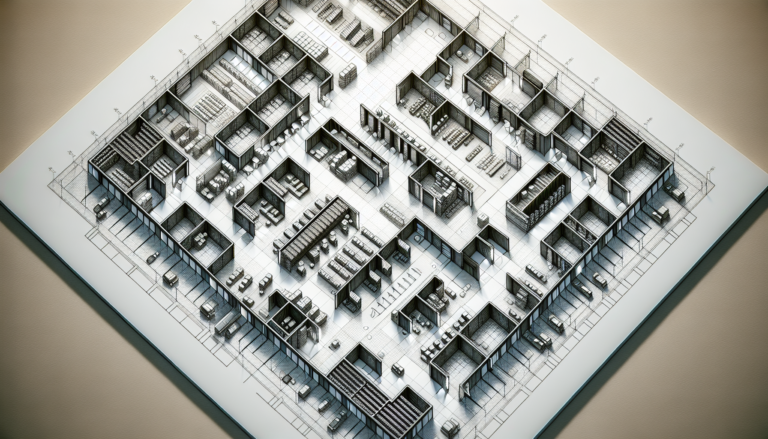

Elevating Warehousing through Strategic Design

People often overlook these storage facilities’ design and layout. Strategic design plays a crucial role in enhancing operational efficiency and safety. Optimizing the layout of a warehouse involves:

Maximizing Space Use is about using vertical storage solutions. It also means using flexible shelving systems. These systems accommodate varying product sizes and volumes.

Streamlining Workflow: Organizing inventory and work zones to cut movement. This makes picking and packing faster.

We will add clear signs and paths for pedestrians. We will also add ergonomic solutions to prevent injuries.

Efficient design boosts productivity. It also extends a warehouse’s life by fitting warehouse growth and tech upgrades. It does this without needing big structural changes.

Advanced technologies are transforming warehousing

In warehousing, technological advances aren’t just additions. They are essential. They redefine what these facilities can do. Some of the cutting-edge technologies include:

Drones for inventory management.

Using scanning drones to do inventory checks cuts the time and labor for manual counting.

Artificial Intelligence (AI)

AI algorithms predict demand patterns. They also optimize stock levels. They suggest the most efficient routes for picking and packing.

Internet of Things (IoT)

IoT devices track and monitor warehouse conditions in real time. They ensure they store products well. This is crucial for perishable goods.

These technologies make warehouse operations smoother. They provide new data and analytics that were previously unattainable. They lead to better decisions.

Sustainable Practices in Warehousing

Sustainability is a key theme in warehouse management. It’s driven by environmental concerns and cost-efficiency goals. Warehouse eco-practices slash carbon emissions and trim expenses for companies.

Important strategies include company efficiency. This means installing solar panels. It means using efficient lighting. And it means optimizing heating, ventilation, and air-conditioning systems.

Waste Reduction: Install recycling programs and use returnable packaging materials to cut waste.

Opt for materials born from recycling or responsible harvesting practices. Use them for warehouse construction and maintenance.

These practices help businesses meet their corporate social responsibility goals. They also lead to long-term savings and operational efficiencies.

Enhancing Security Measures in Warehouses

Security in warehousing extends beyond physical measures to protect against theft or damage. It also involves data security. This is especially true with the increased use of digital systems like WMS. Key security measures include:

Advanced Surveillance Systems use high-definition cameras, motion sensors, and access control systems. They’ve checked and controlled access to the warehouse.

Cybersecurity protocols protect digital systems and data. They do this through encryption, secure user logins, and regular security audits.

We train staff on physical and digital security. This is to ensure that they know the latest risks and prevention techniques.

Addressing Labor Challenges in Warehousing

Labor management remains a significant challenge in warehousing. Managing warehouse staff well is critical to success. It’s key from hiring to retaining and productivity. Strategies to improve labor management include:

Automated and Ergonomic Solutions: Use technology to cut labor. Design workspaces to reduce strain.

Skill Development and Training: We’ve provided ongoing training. It enhances skills and increases job satisfaction.

Use incentive programs. They should reward good employee performance. They also boost morale and productivity.

Trends in Warehouse Robotics

Robotics and automation are new in warehousing. They’re not a trend – they’re a big change. The demand for faster, more accurate order fulfillment is growing, especially in e-commerce. Robotic technology is becoming indispensable.

AMRs, AGVs, and robotic picking systems are streamlining operations. They reduce human error and boost productivity. These innovations allow warehouses to operate 24/7. They need fewer workers and are safer.

A close look at the latest robots could show how they can revolutionize warehouses.

Integration of blockchain technology in warehousing.

More and more people see the potential of blockchain technology. They see it as going beyond cryptocurrencies. This is especially true in supply chain management and warehousing.

Its see-through, unchanging ledger lets us track every item in a warehouse in real time.

This clarity improves security. It helps with inventory and cuts losses from fake goods. It also speeds up recalls.

Discussing blockchain integration could give your readers insights. It shows how warehousing is getting safer and more efficient. It also fosters trust across the supply chain.

Impact of Global Supply Shifts on Warehousing

Global supply chains always change. Many factors cause these changes. They include trade policies, economic shifts, and geopolitical tensions. These shifts have a direct impact on warehousing strategies and operations.

For instance, tariffs may prompt companies to change how they get goods. This will affect how they use and where they put warehouses. Also, some industries want to restore. This affects the demand for warehousing in some regions.

Studying these impacts can help readers understand. It shows the need for flexible and resilient warehouse strategies. They’ve helped warehouses respond well to global changes.

Conclusion: The future of warehousing.

The future of warehousing lies in integrating technology, management, and innovation. These strategies drive efficiency, cut costs, and improve service. Businesses evolve, and the strategies used in warehousing must evolve, too. This is needed to stay competitive in a fast-changing marketplace.

Frequently Asked Questions

Q: What is the difference between a warehouse and warehousing?

Warehousing involves the industry’s inventory storage. It includes the organization and distribution of goods. In contrast, a warehouse refers to the actual physical storage facilities.

Q: How does a WMS improve warehousing operations?

It improves warehousing. It optimizes inventory tracking and provides real-time visibility. It reduces errors and allows for growth. This system’s capabilities are in management. Make streamlined processes possible, significantly boosting overall efficiency within the warehouse.

Q: What are some tactics used in inventory control within a warehouse?

Warehouse inventory management uses strategies. These include constant real-time monitoring and predicting demand. They also include using space well. They use just-in-time methods and tech to reorder alerts. This all ensures stock levels are optimal and operations run smoothly.

Q: Can distribution center logistics directly affect customer satisfaction?

Reliable warehousing logistics ensure that orders are accurately fulfilled on schedule. They cut mistakes and increase customer satisfaction.

Frequently Asked Questions

Q: What is the difference between a warehouse and warehousing?

Warehousing involves the warehousing industry’s comprehensive inventory storage process, organization, and goods distribution. In contrast, a warehouse refers to the actual physical storage facilities.

Q: How does a WMS improve warehousing operations?

It enhances warehousing operations by optimizing inventory tracking, providing real-time visibility, minimizing errors, and allowing scalability. This system’s capabilities are in management. Make streamlined processes possible, significantly boosting overall efficiency within the warehouse.

Q: What are some tactics used in inventory control within a warehouse?

Warehouse inventory management employs strategies such as constant monitoring in real-time, predicting demand, maximizing inventory storage space use, Using Just-in-Time methods, and leveraging technology for automated reorder alerts to ensure stock levels are at their best and operations run smoothly.

Q: Can distribution center logistics directly affect customer satisfaction?

Certainly, effective warehousing logistics guarantee prompt and precise order execution, minimizing mistakes and increasing customer satisfaction.