Storage Warehouse Efficiency: Powerful Strategies for 2026

A storage warehouse is more than space; it’s a crucial component of your business operations and logistics. Are you faced with efficiency challenges or space dilemmas?

Key Takeaways

- Optimizing warehouse storage involves adding features. These features include climate and security systems. They protect goods and boost efficiency. It also requires a layout to improve inventory access and maximize storage capacity.

- The choice of a warehouse must be strategic. It should consider growth potential, costs, location, and future business needs. It must balance immediate needs and long-term growth.

- Advanced technologies, like automation, robotics, and inventory software, are critical. They modernize warehouses, improve efficiency, and cut labor costs. Green initiatives support sustainability and may result in cost savings.

Understanding Storage Warehouses

Essentially, a warehouse is a specialized building meant to house goods. However, these structures are much more than oversized containers for products.

They play a crucial role in both warehouse and storage, differentiating between the two concepts and highlighting their distinct roles in inventory management. They are vital to many businesses, providing the space needed to store inventory.

Warehouses support activities in many industries. These include retail, manufacturing, e-commerce, and small businesses.

Essential Features of a Storage Warehouse

A warehouse dedicated to storage is like a well-crafted machine. It has several essential elements. They guarantee smooth functioning.

Such components include temperature regulation and protection measures, strategic arrangement, and design. They are focused on using space well and improving efficiency.

Exploring how these features work and their value will illuminate their critical role in the warehouse. Each aspect will be explored thoroughly to help you choose the right storage solution based on your specific business needs.

Climate Control

A climate-controlled warehouse acts as a waterproof guard for your items. A cold storage warehouse is particularly crucial for the food industry, ensuring perishables are kept at optimal temperatures.

People use sophisticated machinery to keep this environment at the right conditions, and they use HVAC units and devices to control moisture.

This ensures that temperature fluctuations, humidity levels, and air purity are managed rigorously.

Consider the advantages of maximizing space through self-storage solutions for commodities like:

medications

electronic components

fine art

rare wines

Imagine those goods housed in a facility devoid of this reinforced brick sanctuary. The likely outcome would be compromised merchandise and squandered assets.

Upholding this shield can be difficult. It means following strict rules and incurring somewhat higher costs. However, these incremental costs pale compared to potential losses incurred without environmental regulation mechanisms.

This is especially true when clever stacking can cut costs to keep these ideal conditions.

Security Systems

Securing a warehouse involves more than locking up when the day is over. It needs a full system to protect merchandise. This system must guard against theft, spoilage, and environmental harm.

Security includes parts like motion detectors, alarms, and sensors. They can identify glass breaking. They create a safety net against illicit entry while maintaining product integrity.

Surveillance equipment with night vision capabilities offers around-the-clock monitoring in real-time. Meanwhile, sophisticated access control systems provide an additional barrier for enhanced defense.

Implementing these security elements strategically in the storage facility is crucial.

Regular audits and proper insurance are key to protecting the stored goods and your business. This is vital for more than just product preservation. It’s about fortifying the entirety of one’s commercial venture.

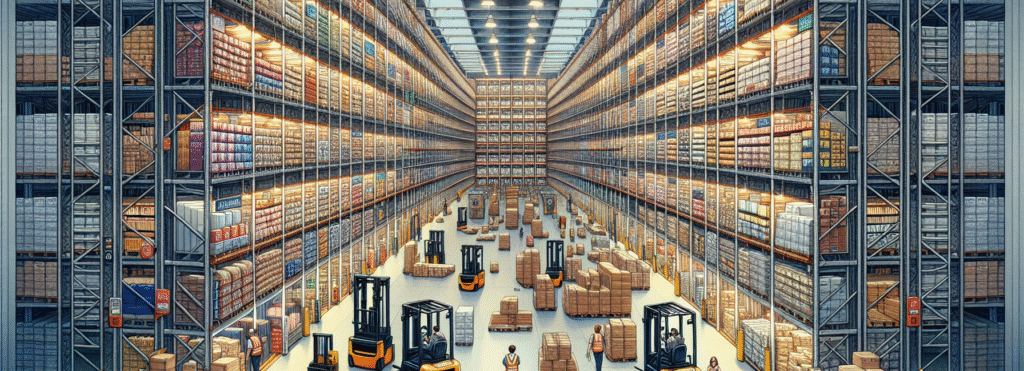

Organization and Layout

A configuration is like a well-tuned performance. Every part has a place and role. This role boosts the group’s effectiveness. Pallet racking systems are essential components for large and busy warehouses, designed to efficiently store inventory received in large boxes. This applies to all, from the storage to each item in stock.

Imagine a group with a musician playing out of sync or lacking an instrument. The harmony would be disrupted. In this light, warehousing demands that inventory is carefully arranged. It must be done according to how often items move.

Those in high demand should be easy to find. Infrequently moved products are placed more strategically.

A good organization is not just arranging goods. It also means using space well.

Product categorization

Dimensions

Configuration

Rotation needs

Using the right small containers and sizing them well lets you fill them fully. This avoids leaving space. Doing this greatly boosts efficiency in using space.

Choosing the Right Warehouse

Securing the perfect warehouse for your business, especially when considering warehousing storage, is comparable to finding the ultimate tailored suit. It must accommodate your current requirements while also providing space for future expansion.

Choose the location for efficient distribution and financial viability. The question then becomes how to ensure your selected warehouse meets all these criteria. Let’s examine this matter more thoroughly.

Assessing Your Storage Needs

When choosing the appropriate warehouse, you must thoroughly comprehend your storage needs. Consideration should be given to present inventory needs and potential expansion.

This process is akin to purchasing a suit. You wouldn’t opt for one that is straight-fitting with no allowance for movement. Evaluate your storage needs. Make sure you have enough space for growth. This will avoid the need for frequent moves or changes.

Comparing Costs and Benefits

Expenses related to operating a warehouse comprise the following:

Rental fees

Utility bills

Workforce wages

Insurance premiums

Upkeep charges

Property taxes

Inventory management expenditures

Costs of processing orders

The expenses fluctuate. They depend on factors like the warehouse’s size and location, the services it provides, the shipments it handles, and the type of merchandise housed.

The labor cost is especially affected by how large and intricate a warehouse is.

Focusing only on spending would be shortsighted. Warehouses can also bring big benefits. For example, logistics providers may offer affordable warehousing and distribution solutions. They take advantage of bulk operations’ cost reductions. They’ve experienced personnel.

Warehouses in good spots can lower transit costs. They also tap into a bigger market, offering monetary benefits. Location greatly determines rates for these services. But, it can bring big rewards if chosen wisely.

Accessibility and Convenience

Determining the perfect warehouse involves evaluating its ease of access and convenience. A warehouse is an essential part of the supply chain, far more than merely a storage location for goods. Accessibility is crucial in facilitating efficient logistics operations.

Consider if your chosen warehouse is positioned far from the primary transport arteries. This would lead to late deliveries and disgruntled customers. Customers think highly of warehouses with simple entry. They ensure smooth, damage-free, and well-temperature-managed interactions.

Innovative Storage Solutions for Improved Efficiency

In the rapidly changing business realm, embracing innovation is essential for triumph. This is especially true in storage warehouses, where new technology transforms processes and adds efficiency.

Self storage units are designed for individuals and small businesses, offering secure, lockable spaces for personal belongings and inventory.

Are you curious about the practical application of these groundbreaking developments? We’re set. We’re proud of many pioneering solutions that are redefining the warehouse sector.

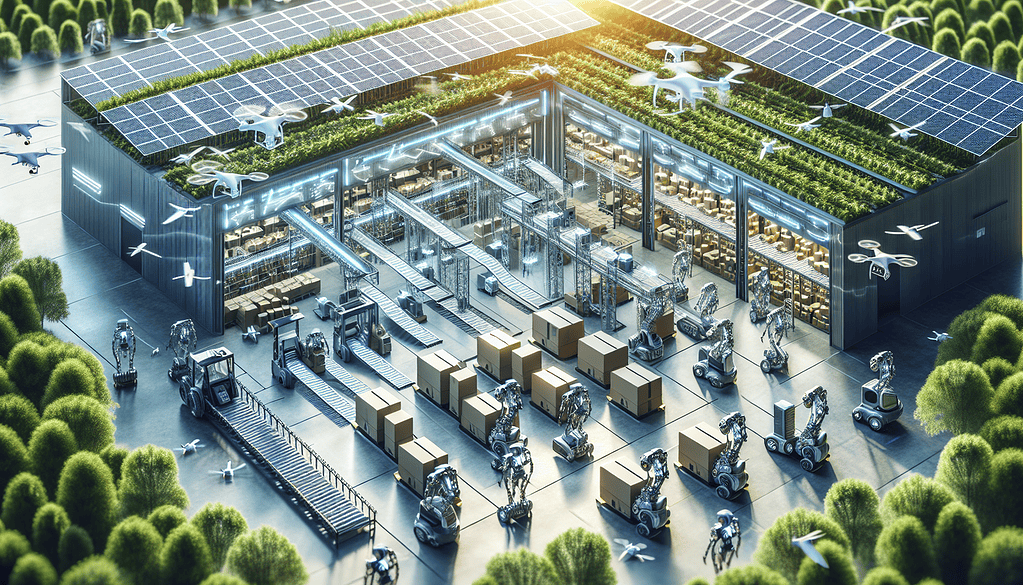

Automation and Robotics

Automation and robotics were once seen as a glimpse into the future. Now, they are essential in warehousing.

These technologies improve storage efficiency. They also streamline processes in facilities and greatly cut labor costs. They do this by turning warehouses into high-tech centers. The deployment of automation in these spaces can be seen through:

AS/RS enhances space use. They also cut the need for manual handling.

Automated Guided Vehicles (AGVs) that expedite product movement across various points

Conveyor systems designed to facilitate seamless internal transit of goods

These technological advances are changing how things are done in warehouses and on docks. They are driving up efficiency and overall productivity. This happens by integrating advanced tools with unit-level precision.

Adding Autonomous Mobile Robots (AMRs) to Pick-and-Place Robotics automates basic tasks, such as picking and inventory logistics.

This transition frees employees. It lets them focus on more thinking-heavy jobs, which add important strategic value rather than routine tasks.

Inventory Management Software

The digital control center for warehouse activities is found in inventory management software. This tool delivers several advantages, such as:

The ability to monitor inventory instantaneously and with full visibility

Precise regulation of available stock quantities

Avoidance of common problems like excess inventory and product shortages

Improvement in the efficiency with which space is used

Real-time observation of stock levels

Demand prediction capabilities that bolster overall operational efficiency

Powerful reporting and analysis tools let warehouse supervisors track performance. They can find inefficiencies and make data-based choices. Using robotics and data visualization, they refine logistics, from receiving goods to dispatching orders.

Green Initiatives

Today, global warming and environmental decline are big concerns. So, adopting green practices is not just a fad but a vital move.

Sustainable warehousing involves using energy-saving lights and policies that cut waste. These things help the environment and improve warehouse operations.

Warehouses can cut greenhouse gas emissions by using eco-friendly transport, including electric or hybrid vehicles, and refining delivery routes.

Utilizing sustainable packaging materials does more than aid environmental conservation. It can boost warehouse space utilization and result in financial savings.

Remember that these environmentally responsible actions benefit our planet and commerce alike. Numerous environmental laws require warehouses to engage in sustainable activities.

Case Studies: Warehouse Implementations

While discussing the what and how, let’s explore the ‘why’ through real-world examples. The case studies highlight how optimizing warehouse space can help businesses grow, enable fast inventory access, and cut costs.

For instance, a furniture retailer saw a 25% sales increase after revamping its warehouse to accommodate a wider range of products and improve inventory turnover.

Similarly, a manufacturing company reduced the time it takes to ship orders by 30% by installing automated storage and retrieval systems, which enhanced customer satisfaction.

An e-commerce company redesigned its warehouse layout, adding pick-to-light systems and dynamic racking, which improved picking efficiency by 50%. A logistics company also reduced shipment errors by 40% using state-of-the-art inventory software.

Preparing Your Inventory for Storage

Organizing your inventory for storage is akin to setting the scene for a play. This process demands following a checklist to safeguard your items, security, and documentation.

The checklist should include safety rules, cover the right packing methods, and prevent damage during storage or moving.

You must also ensure security measures on this checklist. These include accurate labeling and an organized system of records that keeps tabs on all stored items. These steps help prevent misplacement and damage.

Following these rules can greatly boost warehouse efficiency. A well-set stage is crucial for a great show.

Legal Considerations and Regulations

Managing a warehouse is about more than overseeing storage and inventory. It requires following many legal requirements and rules. These encompass several key areas, such as:

The safety protocols for workers

Ensuring buildings are structurally sound

Observance of equitable wage practices

Oversight of transportation logistics

For example, to be compliant, warehouses must follow various guidelines, which include:

Meeting OSHA regulations means keeping aisles clear. It also means marking exits clearly and having fire safety equipment available.

Adhering to local building codes that affirm the structural integrity of storage facilities

Abiding by labor legislation, such as the FLSA, ensures fair wages and conditions for employees

They follow transportation laws. The laws dictate the safe and lawful movement of goods and proper insurance coverage.

In essence, abiding by these stipulations isn’t merely about avoiding fines. It’s about fostering a warehouse environment that prioritizes efficiency and worker protection.

Summary

We’ve investigated everything from the basics of a warehouse to its key parts. We’ve also discussed picking a good warehouse for your business. We’ve also discussed how new solutions can make it more efficient.

The importance of preparing inventory for storage has been highlighted. Also, the need to handle legal concerns and norms for running a warehouse has been highlighted. Making the most out of your space transcends mere goods storage.

It involves utilizing that area as a strategic asset to propel your business. So, have you prepared yourself to realize the capabilities of your space?

Frequently Asked Questions

Why is climate control important in a warehouse storage system?

Climate control in a warehouse is important. It ensures the best conditions for preserving sensitive items, such as pharmaceuticals, electronics, artwork, and food, and ensures their quality and safety.

What security measures are implemented in a warehouse?

Warehouses have security protocols, including motion detectors, alarms for broken glass, cameras, and strong access control. They defend goods.

These strategies are key. They guard against theft or damage to valuable inventory and assets.

How does inventory management software improve warehouse storage solutions?

It provides accurate real-time inventory tracking, which helps optimize space and control stock levels and demand. This improves organization and command over inventory, smooths out operations, and cuts expenses.

What initiatives can we implement in a warehouse to promote sustainability?

Efficient lights in a warehouse can save energy. They also improve sustainability and cut environmental impact. Reduce waste, use eco-friendly transport, and use eco-friendly packaging.

What legal considerations and regulations apply to warehouse storage systems?

Warehouse operations have critical aspects. They include ensuring worker safety, keeping the building strong, paying fair wages, and legally moving goods. They must also follow OSHA standards, local building codes, labor laws, and transportation regulations.