Six Sigma Warehouse: Boosting Efficiency and Reducing Errors

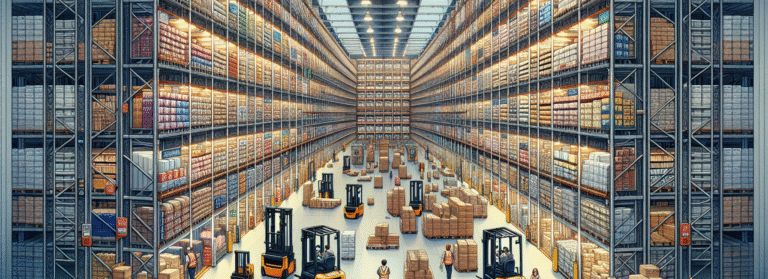

Six Sigma warehouse practices focus on eliminating waste, reducing variation, and improving process accuracy. By applying Six Sigma methodology to warehouse operations, companies can increase productivity, lower costs, and achieve more consistent customer satisfaction.

What is Six Sigma in a Warehouse?

Six Sigma is a process improvement methodology based on data and statistics. In a warehouse, it’s used to:

Reduce picking and shipping errors

Standardize workflows

Improve safety and efficiency

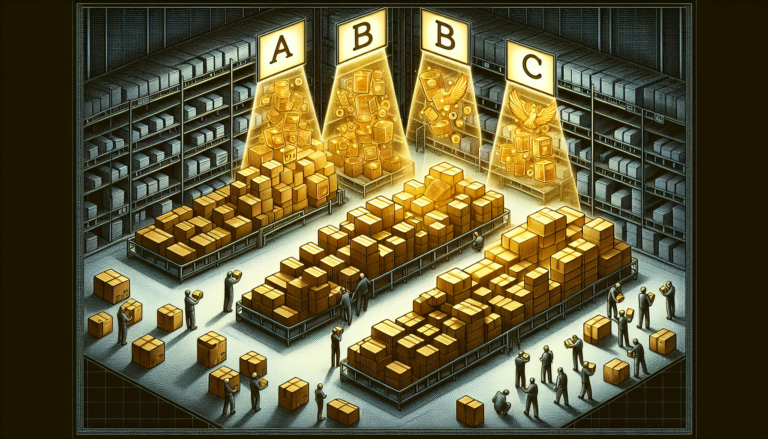

Optimize inventory management

The goal is to achieve near-perfect operations, often measured as no more than 3.4 defects per million opportunities (DPMO).

5 Steps to Implementing a Six Sigma Warehouse

Define – Identify warehouse challenges (errors, delays, space issues).

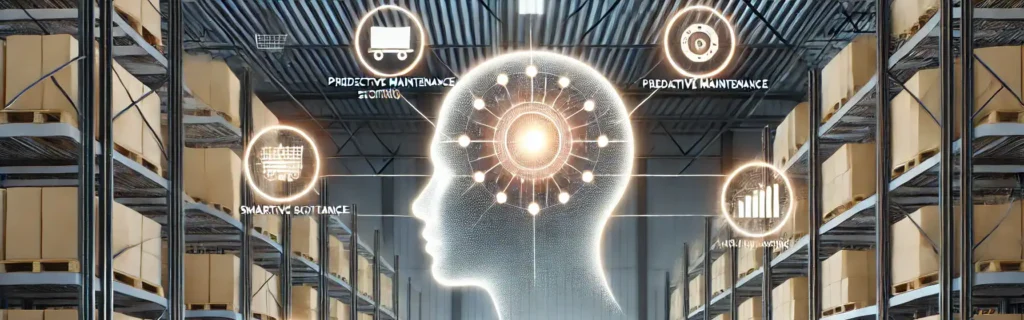

Measure – Collect data on order accuracy, pick times, inventory turns, etc.

Analyze – Find root causes of errors or inefficiencies.

Improve – Apply changes such as slotting optimization, automation, or training.

Control – Monitor results and ensure improvements are sustained.

Key Benefits of Six Sigma in Warehousing

Higher Accuracy – Fewer picking and shipping mistakes.

Reduced Costs – Less waste, fewer returns, and lower labor costs.

Improved Safety – Standardized workflows reduce accidents.

Faster Fulfillment – Leaner processes lead to improved customer satisfaction.

Stronger ROI – Long-term cost savings from efficiency gains.

Challenges in Applying Six Sigma to Warehousing

Requires strong leadership buy-in

Needs a consistent data tracking system

Employee training is essential for a culture shift

Initial implementation can be resource-intensive

Conclusion

A Six Sigma warehouse isn’t built overnight. It requires commitment, data-driven leadership, and ongoing monitoring. But the payoff is significant: lower costs, higher efficiency, and a competitive edge in an increasingly demanding supply chain.