AI in Warehousing Pallet Putaway: Real-Time Smarter Storage

If you’ve ever walked a warehouse floor, you’ve seen the problem. Forklift drivers zig-zagging through aisles, dropping pallets wherever there’s space. It feels efficient in the moment, but it creates longer travel times, bottlenecks, and frustrated operators.

Most managers attack this with training or more labor. The truth? The problem isn’t people. It’s placement.

This is where AI in warehousing pallet putaway becomes a game-changer. Instead of firefighting, AI tools optimize locations in real-time — cutting travel and creating a smoother pallet flow. This is ‘System Directed Putaway’ on steroids!

AI in Warehousing Pallet Putaway: Best Location Every Time

When you think about pallet putaway, the first rule is simple: the pallet needs to be placed in the right zone based on where it’s going to ship from.

If it’s pallet in / pallet out, there are really only two things that matter:

It’s staged close to its departure door.

It isn’t mixed in an aisle with case-pick activity — you don’t want forklifts competing with order pickers.

That defines a non-order-picker aisle — reserved strictly for full pallet moves.

But warehouses rarely stay that clean. Many SKUs are picked in multiple ways. Take printer paper as an example:

Full pallets go to a large retail customer.

Cases go to a mid-size distributor.

Eaches are sold through e-commerce.

In this example, one SKU must be available in multiple locations to enable simultaneous use of different picking methods. The challenge is ensuring that inventory is split correctly — enough pallets are staged for full-pallet orders, cases are accessible for case picking, and eaches are kept in smaller pick faces for e-commerce.

This is where AI in warehousing pallet putaway comes into play. AI doesn’t just look at where space is available. It looks at:

Historical order patterns by customer type (pallet vs. case vs. each).

Velocity of each picking method.

Zone definitions in your warehouse layout (non-order-picker aisles, case-pick zones, e-com areas).

With this, AI can not only recommend the right zone but also the optimal split of inventory across those zones. Instead of a supervisor guessing how much printer paper should be staged as full pallets versus broken into case-pick slots, AI makes that decision based on real outbound data and real-time customer ordering patterns.

The result? Equipment and people are kept separate, the flow is smoother, and order fulfillment aligns with how your customers actually buy.

👉 In other words, AI doesn’t replace the basic warehouse logic you already know — it scales it across every SKU, every day.

How AI in Pallet Putaway Works (The Printer Paper Example)

AI in warehousing pallet putaway isn’t about rewriting the rules you already know — it’s about scaling them across thousands of SKUs with data-driven precision. Let’s use printer paper as an example.

Step 1: Gather the Data

The WMS already knows how printer paper has been shipped historically:

60% of orders → full pallet (large customers).

30% of orders → case pick (mid-size distributors).

10% of orders → each pick (e-commerce).

Step 2: Define the Zones

Pallet-in/pallet-out zone, close to the dock doors.

Case-pick zone, designed for carton flow or selective racking.

Each-pick zone, typically smaller slots closer to packing.

Step 3: AI Allocation

Instead of a supervisor “eyeballing” how much paper to drop in each zone, AI automatically allocates inventory:

6 pallets staged in the pallet zone.

3 pallets broken down for case-pick.

1 pallet broken down into each-pick locations.

The model can adjust this daily (or even hourly) based on actual order flow. If e-commerce spikes, the AI shifts more inventory to the each-pick zone before you run out.

Step 4: Continuous Learning

Every order teaches the AI model. Over time, it learns:

Which zones fill fastest.

Which picking methods cause congestion.

Where to rebalance inventory before a bottleneck happens.

👉 In practice, this means AI makes the same decisions you would — but at scale, continuously, and without guesswork.

This ties your practical rules (zone logic, separation of equipment/people, SKU split) into an AI-driven framework that’s simple for readers to imagine implementing.

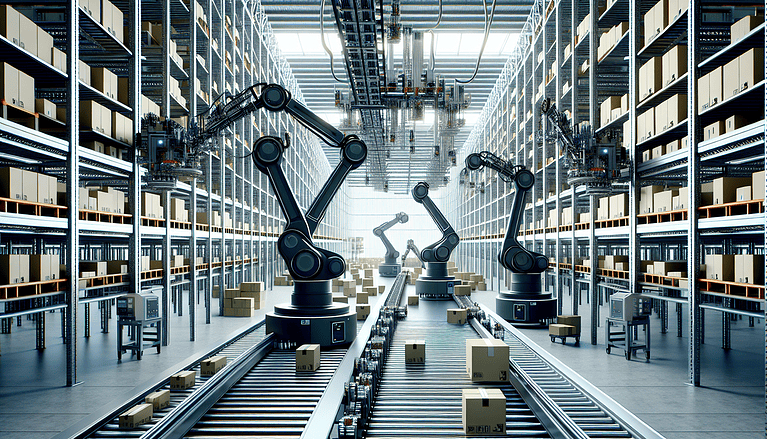

AI in Warehousing Pallet Putaway: The One-Aisle Pilot

Here’s the beauty of AI: you don’t have to flip the whole warehouse overnight. You can start with one aisle.

Feed historical pallet moves into an AI model.

Let it recommend putaway locations based on velocity, cube, and retrieval patterns.

Compare forklift travel before vs. after.

In one pilot I’ve seen, travel time dropped 18% in a single week. Same drivers, same equipment — just smarter placement.

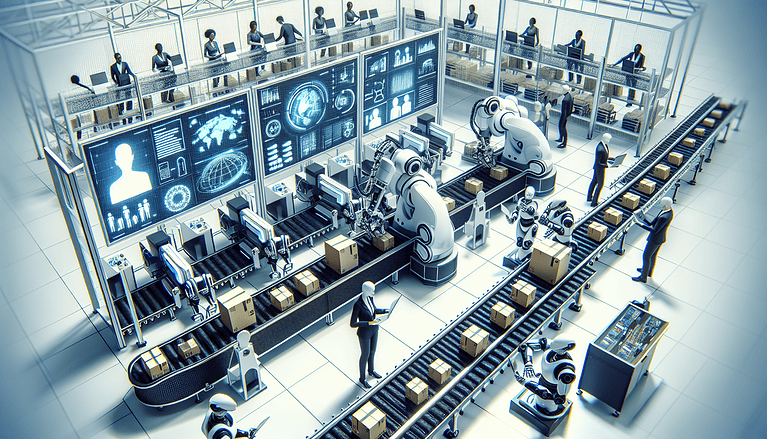

How AI in Pallet Putaway Works (Without the Jargon)

Step 1: Data In → Pull SKU velocity and pallet history (already in your WMS or spreadsheets).

Step 2: AI Model → Instead of static slotting rules, AI learns and updates recommendations daily.

Step 3: Actionable Output → Forklift drivers get directed putaway instructions that reduce backtracking.

👉 It’s not magic. It’s just removing guesswork from the most basic warehouse decision: where does this pallet go?

Why Smarter Putaway Matters

Labor Efficiency → Less zig-zagging means drivers move more product in less time.

Faster Throughput → Pallets flow in and out cleaner, reducing dock congestion.

Scalable Proof → If one aisle works, scaling to the next ten aisles is just turning on more data.

Real Talk: What AI Won’t Do

AI won’t replace your forklift drivers. It won’t eliminate every travel mile. And it won’t work if your data is garbage.

However, it will provide a repeatable and scalable way to stop guessing where pallets belong.

McKinsey notes that slotting optimization alone can improve warehouse productivity by up to 20% — and AI takes this beyond periodic slotting into continuous improvement.

Read McKinsey’s analysis on warehouse automation

If you’re interested in how putaway ties into storage design, check out my post on Right-Sizing Warehouse Locations — because AI is only as good as the space it optimizes.

Final Thought

Firefighting pallet putaway with extra labor or quick fixes won’t scale. Starting with AI in warehousing pallet putaway and a single aisle proves that smarter decisions can deliver immediate ROI.

The adaptive warehouse doesn’t wait for problems — it prevents them, one aisle at a time.