Green Warehousing Practices: Strategies for a Sustainable Supply Chain

Sustainability isn’t just a buzzword — it’s becoming a competitive advantage in logistics. Green warehousing practices help reduce environmental impact, lower operating costs, and align businesses with customer and regulatory expectations. From energy-efficient lighting to waste reduction and renewable power, today’s warehouses are adopting eco-friendly strategies that strengthen both the bottom line and brand reputation.

Key Takeaways

Green warehousing reduces energy use, waste, and emissions.

Practices include solar power, LED lighting, eco-friendly packaging, and better space utilization.

Benefits include lower costs, stronger ESG performance, and improved customer perception.

Technology like WMS, IoT sensors, and automation supports sustainability goals.

Why Green Warehousing Matters

Warehouses account for a significant portion of energy use and waste in the supply chain. With e-commerce growth and increased throughput, the need for sustainable operations has never been higher. Green warehousing not only supports global sustainability goals but also delivers direct financial benefits through increased efficiency and reduced energy consumption.

7 Smart Green Warehousing Practices

1. Energy-Efficient Lighting

Switching to LED high-bay lighting can cut warehouse energy costs by up to 70%. Motion sensors ensure lights are only used when needed.

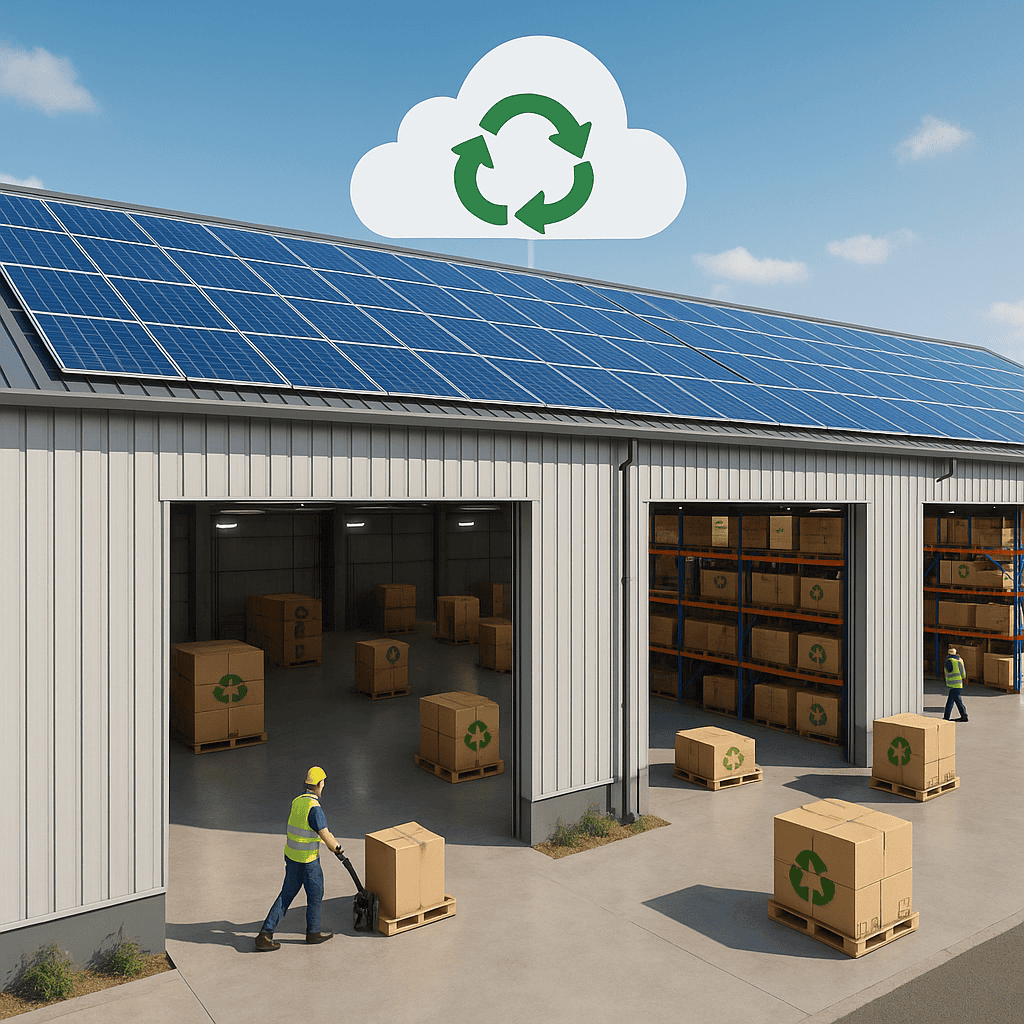

2. Solar and Renewable Energy

Rooftop solar panels and renewable energy contracts reduce dependency on fossil fuels. Many warehouses now achieve partial or full energy independence.

3. Sustainable Packaging

Replace single-use plastics with recyclable or biodegradable packaging. Partner with eco-friendly packaging vendors to reduce landfill waste.

4. Efficient HVAC and Climate Control

High-efficiency HVAC systems, natural ventilation, and insulated warehouse designs minimize energy waste in temperature-sensitive facilities.

5. Waste Reduction and Recycling

Adopt clear recycling stations and reuse pallets, cardboard, and stretch wrap. Zero-waste initiatives keep materials in circulation.

6. Space Optimization

Better warehouse layout design reduces travel time and energy use for forklifts and AMRs. Vertical storage solutions maximize space without new construction.

7. Green Transportation Partnerships

Collaborate with 3PLs and carriers that use electric vehicles (EVs) or alternative fuels, cutting CO₂ emissions across the supply chain.

Technology Driving Green Warehousing

Digital tools make sustainability measurable. IoT sensors monitor energy use in real-time, while Warehouse Management Systems (WMS) reduce wasted space and improve slotting efficiency. Automation, robotics, and AI-driven forecasting also optimize resources, preventing unnecessary movement and excess inventory.

Benefits of Sustainable Warehousing

Cost Savings: Lower energy bills, reduced waste disposal fees, and less packaging.

Compliance: Stay ahead of regulations on emissions and single-use plastics.

Customer Trust: Today’s buyers prefer brands with visible sustainability initiatives.

Resilience: Energy-efficient facilities reduce risk from rising utility costs.

FAQs

What are green warehousing practices?

These strategies reduce energy use, waste, and emissions in warehouse operations while improving efficiency and sustainability.

How do warehouses cut energy consumption?

By installing LED lighting, upgrading HVAC systems, and adopting renewable energy like solar.

Can sustainability reduce costs?

Yes. Lower utility bills, less packaging waste, and optimized operations often result in long-term savings.

What role does technology play in green warehousing?

IoT sensors, WMS, and automation provide the data and tools to track, measure, and optimize sustainable initiatives.