LiDAR in Warehousing: Transforming Safety and Efficiency

Warehouses are packed with movement — forklifts weaving through aisles, workers on foot, conveyors shifting product. Safety, speed, and accuracy depend on knowing where everything is in real time. That’s where LiDAR in warehousing comes in.

LiDAR (Light Detection and Ranging) uses laser pulses to create a 3D map of the environment. In simple terms: it helps machines and people “see” the warehouse with extreme precision. And in 2025, LiDAR in warehousing is moving from robotics labs into everyday operations.

Why LiDAR in Warehousing Matters

Traditional cameras struggle with dust, changes in lighting, and blind spots.

Barcodes and RFID are powerful, but they are limited to tagged items.

LiDAR in warehousing creates a real-time 3D model of everything — racks, pallets, people, and vehicles.

This level of visibility is transforming both safety and efficiency.

Applications of LiDAR in Warehousing

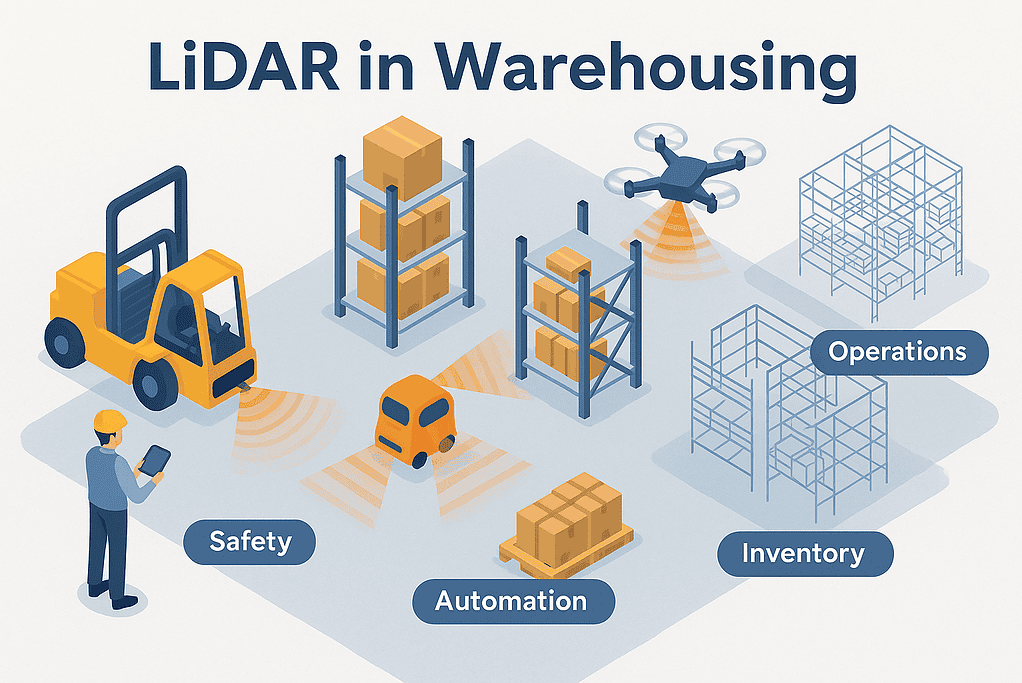

1. Forklift and AGV Navigation

Forklifts and Automated Guided Vehicles (AGVs) equipped with LiDAR can navigate aisles safely, detect obstacles instantly, and avoid collisions. Unlike fixed floor markers, LiDAR adapts dynamically to layout changes.

2. Worker Safety and Collision Prevention

LiDAR in warehousing can create virtual safety zones. If a worker steps too close to moving equipment, the system slows or stops operations. This proactive approach reduces accidents and builds confidence on the floor.

3. Inventory Scanning and Verification

Mounted LiDAR units can scan pallets and shelves, measuring dimensions, verifying locations, and spotting misplaced inventory. Unlike manual checks, LiDAR data is continuous and automated.

4. Real-Time Facility Mapping

Warehouses change constantly. LiDAR provides live digital twins of the facility, so managers always know the exact layout, aisle widths, and storage utilization. This is critical for slotting, re-racking, or expansion planning.

5. Enhanced Robotics and Automation

From robotic arms picking products to drones scanning aisles, LiDAR in warehousing gives machines the “eyes” they need to operate safely alongside humans.

Benefits of LiDAR in Warehousing

Improved Safety: Fewer collisions and better worker protection.

Higher Efficiency: Smarter forklift routing, accurate slotting, faster picks.

Reduced Errors: Real-time verification cuts misplacements.

Flexibility: Works even in low light, dusty conditions, or changing layouts.

Challenges of LiDAR in Warehousing

Cost: LiDAR units are dropping in price, but still require investment.

Integration: LiDAR must sync with WMS, LMS, and robotics systems.

Training: Staff must learn how to interpret and use LiDAR-driven insights.

The Future of LiDAR in Warehousing

By 2030, expect LiDAR in warehousing to be as common as barcode scanners today. It will power fully autonomous forklifts, AI-driven slotting, and continuous facility optimization. Combined with AI, LiDAR will help warehouses adapt in real time — adjusting labor, routing, and safety protocols automatically.

Conclusion

LiDAR in warehousing isn’t just futuristic tech — it’s a practical solution that improves safety, cuts errors, and prepares operations for automation. For leaders balancing labor shortages, rising demand, and safety pressures, LiDAR offers a way to see problems before they happen — literally.

Frequently Asked Questions About LiDAR in Warehousing

What is LiDAR in warehousing?

LiDAR in warehousing utilizes laser pulses to create a 3D map of the warehouse, enabling machines and personnel to operate safely and efficiently.

How does LiDAR improve forklift safety?

Forklifts equipped with LiDAR can detect obstacles, stop before collisions occur, and reroute in real-time, thereby reducing accidents and protecting workers.

Can LiDAR track inventory?

Yes. LiDAR in warehousing scans pallets, shelves, and racks to measure dimensions, confirm placement, and spot errors instantly.

What are the main benefits of LiDAR in warehousing?

LiDAR in warehousing improves safety, boosts productivity, reduces errors, and adapts to changing layouts better than cameras or barcodes alone.