Computer Vision in Warehousing: The Eyes That Unlock an Intelligent DC

Computer vision in warehousing is no longer a lab experiment—it’s a practical edge. With AI-enabled cameras and analytics at the edge, facilities can see what scans miss: misrouted pallets, damaged cartons, unsafe interactions between people and forklifts, and dwell time patterns that reveal bottlenecks. The result is fewer errors, higher throughput, and safer floors. This guide cuts through hype to show what computer vision really does, who the main players are, and how to start small, prove ROI, and scale with confidence.

What Computer Vision Actually Delivers on the Floor

Touchless inventory awareness: Detects SKUs, pallets, and tote IDs without manual scans.

Automated quality checks: Flags crushed corners, broken stretch wrap, and wrong labels before shipment.

Safety and compliance: Identifies missing PPE, unsafe forklift speed, aisle encroachments, and near misses.

Throughput intelligence: Heatmaps of congestion, pick face dwell times, dock door utilization.

Exception-first operations: Instead of measuring everything, it surfaces what needs action right now.

9 High-Impact Use Cases (with ROI cues)

Inbound pallet verification: Count, label match, and damage detection as pallets enter.

Pick face compliance: Empty slot detection, mis-slot alerts, and forward-pick health.

Pack station QA: Carton dimensioning, label presence/placement, seal quality.

Load verification at the dock: Pallet count and position checks are performed before sealing the trailer.

Forklift-pedestrian protection: Geofenced alerts, proximity violations, near-miss analytics.

Cycle count assist: Vision-assisted counts in high-discrepancy zones to cut recount labor.

Returns triage: Visible defect classification to speed RMA decisions.

Cold chain watch: Frost/condensation signals on doors and curtains, door-open time capture.

Kitting/case-build checks: Verify assembly completeness with visual prompts.

Fast ROI pattern: start where rework, chargebacks, or injuries are concentrated, then let those savings fund the next use case.

The Market Landscape — Who’s Building the “Eyes”

(A blend of vision platforms, sensors, and robotics tightly integrated for warehousing.)

Vision Platforms & Sensors: Cognex, Zebra, SICK, IDS, Basler, Huddly, Axis, Hikvision, Intel RealSense, NVIDIA Metropolis-ready partners.

Robotics + Vision: Locus Robotics, GreyOrange, Seegrid, Vecna Robotics, Mujin, Plus One Robotics, Covariant.

AS/RS & Materials Handling with Vision: Dematic, Daifuku, SSI Schäfer, Knapp, Vanderlande, OPEX.

Retrofit-friendly analytics layers: Robovision, Viso Suite, Vantiq-style event processing, custom edge on NVIDIA Jetson.

Integrator note for your audience: Pick vendors that speak “warehouse”—WMS/WES events, ASN data, and exception workflows—not just generic AI.

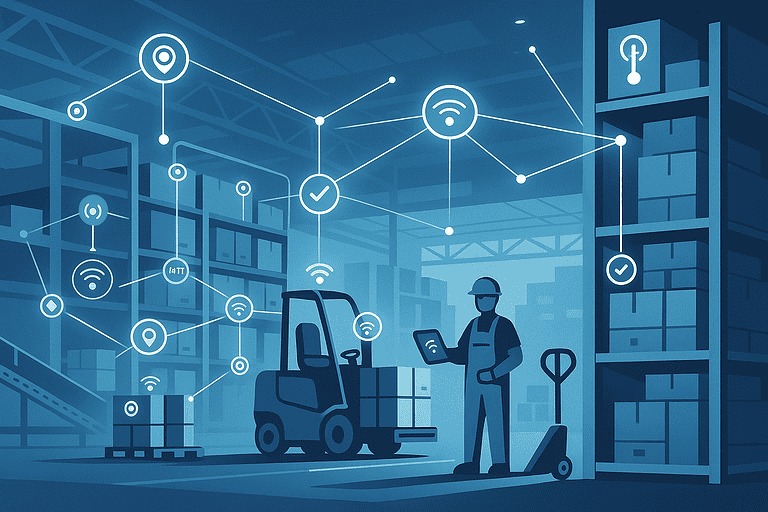

Architecture That Works in Real Warehouses

Cameras you already have: Many CCTV feeds become data sources with new edge models.

Edge inference: Low-latency boxes (Jetson/Intel NPU) next to lines; only events go to the cloud.

Data plumbing: Integrate with WMS/WES/TMS via webhooks or message bus, allowing vision to “act,” not just “show.”

Human-in-the-loop: Review queues for borderline detections keep trust high while models improve.

Privacy and security: Blur faces when not needed; store events, not full video, when possible.

Implementation Roadmap — Start Small, Win Fast, Scale

Phase 1: Define the one problem

Select a single, costly issue (e.g., outbound chargebacks for incorrect labels). Quantify baseline.

Phase 2: Pilot at one node

Deploy 2–4 cameras, an edge box, and a lightweight event UI. Connect to your WMS for lookups.

Phase 3: Prove the metric

Target a 30–60 day window. Track false positives/negatives, rework avoided, time saved, and safety incidents reduced.

Phase 4: Integrate and automate

Turn detections into actions: create WMS tasks, send dock alerts, trigger andon lights.

Phase 5: Scale with a playbook

Template the camera positions, inference settings, and dashboards. Roll line-by-line, site-by-site.

Build vs. Buy vs. Partner — A Practical Decision

Buy when the use case is common and you want speed and support.

Build when your processes are unique and you have a strong data talent team.

Partner when you’re time-boxed and need warehousing know-how plus customizations.

Tip for integrators: Offer “vision as a feature” inside larger projects—dock, pack, palletizing—so customers see results without a separate program.

Data, Governance, and Change Management

Label your wins: Standardize how you track “errors prevented” and “minutes saved.”

Keep humans in control: Train supervisors on the review UI; make it part of the daily huddle.

Model lifecycle: Version, test, and promote models like software. Keep a rollback path.

Ethics & privacy: Minimum necessary video retention; blur by default in people-focused views.

Costs to Expect (Order-of-Magnitude)

Hardware: $1–3k per camera lane all-in (mounts, lighting, edge share), depending on complexity.

Software: Per-camera or per-site licenses; analytics tiers for events/dashboards.

Integration: 2–6 weeks for a focused pilot with alerts + WMS hooks.

Ongoing: Support, model updates, and periodic re-tuning as product mix changes.

Internal Links (suggested)

Warehouse KPI guide → kpi-for-warehouse

SKU slotting strategies → sku-slotting

AMR companies roundup → amr-companies

RFID vendors in warehouse management → rfid-vendors

Warehouse safety culture → warehouse-safety-culture

External Authority Links (suggested)

NVIDIA Metropolis (vision at the edge for industry)

Cognex resources on logistics vision applications

OSHA forklift safety reference for context on risk reduction

Quick Start Checklist

Pick one use case tied to dollars or injuries

Reuse existing cameras if viable; add lighting where needed

Place an edge box near the line; keep latency local

Connect to WMS/WES for actions, not dashboards alone

Run a 30-day pilot with defined success metrics

Publish the result and scale with your playbook

Conclusion

Computer vision in warehousing is the visual cortex of the modern DC. Start with one painful problem, make detections actionable in your WMS, and let the results finance the next step. The goal isn’t more cameras—it’s fewer errors, safer people, and faster flow.

FAQs

Q1: Do I need new cameras, or can I use what’s installed?

Often you can start with existing CCTV, provided angles and lighting work. Many teams add lighting or reposition a few units for high-confidence detections.

Q2: Will this replace barcode scans?

Not immediately. Vision reduces manual scans in targeted steps. Most sites blend scans for confirmations with vision for exceptions.

Q3: How accurate is it in real life?

With good lighting and angles, 90–98 percent for well-defined tasks is common. Human-in-the-loop reviews handle edge cases.

Q4: What about privacy?

Blur faces when not essential, store short clips around events, and follow least-retention policies.

Q5: How long to prove ROI?

A focused pilot can show savings in 30–60 days if tied to chargebacks, rework, or safety incidents.

Q6: What skills do my team need?

Basic camera setup, a champion for metrics, and light integration skills. Your integrator or vendor can manage model training and updates.