Warehousing Seasonality: Smarter Peaks With AI

AI in warehousing seasonality is quickly becoming the solution to one of the biggest challenges in warehouse operations: peak demand. The holiday surge hits, order volumes spike, and suddenly everything is stretched too thin — labor, space, and patience. Managers scramble to hire hundreds of temps, error rates climb, and costs balloon.

The problem isn’t peak demand itself. It’s that most warehouses react too late. That’s where AI changes the game — turning unpredictable peaks into manageable, even predictable, flows.

Game-Changing Fix #1: Forecast Demand Like Never Before

Traditional forecasting looks at last year’s numbers and guesses. AI looks at:

Sales promotions (planned and unplanned).

Real-time order spikes.

Regional buying patterns.

Even weather data.

Instead of reacting after the warehouse is already on fire, AI forecasts demand weeks (or even hours) ahead — giving you time to staff, stock, and slot smarter.

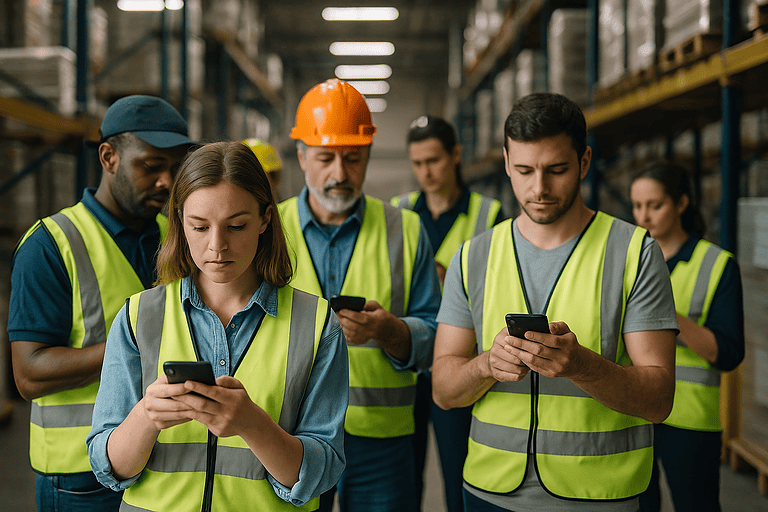

Game-Changing Fix #2: Smarter Labor Planning

Hiring 500 temps every holiday season is a band-aid. AI-driven scheduling apps (like we explored in AI in Warehousing Scheduling) flex labor intelligently:

Predict labor needs down to the hour.

Incentivize workers with surge pay for hard-to-fill shifts.

Target the right associates instead of sending a message to the entire team.

The result: fewer temps, more consistency, and happier employees.

Game-Changing Fix #3: Inventory That Flexes with Demand

Seasonal peaks often expose inventory blind spots. AI can rebalance stock by:

Allocating high-velocity SKUs closer to pack-out.

Splitting SKUs across pallets, cases, and each zone (think printer paper again).

Predicting replenishment needs in real time to avoid stockouts mid-peak.

Game-Changing Fix #4: Optimize Flow Under Pressure

When the docks are jammed and forklifts are stacked three deep, chaos multiplies. AI helps by:

Predicting dock congestion before it happens.

Adjusting inbound scheduling dynamically.

Directing forklifts and AMRs with shortest-path logic to cut cycle times.

Game-Changing Fix #5: Learn and Improve Every Peak

Here’s where AI shines. Each peak season becomes training data for the next. Instead of dreading Q4, your warehouse gets smarter every year — continuously improving without a 3-month post-mortem.

Final Thought: AI in Warehousing Seasonality

Peak doesn’t have to mean panic. With AI in warehousing seasonality, forecasting, labor planning, and inventory flow all adapt in real time.

The adaptive warehouse doesn’t just survive seasonal demand — it thrives on it.

According to McKinsey, AI-driven forecasting and labor planning can reduce seasonal operating costs by up to 20%, while also improving customer service during peak periods.

👉 See AI in Warehousing Turnover Costs to learn how AI reduces churn when hiring for peak.

👉 Explore AI in Warehousing Scheduling for more on surge pay and dynamic scheduling.