Warehousing Turnover Costs: How AI Reduces Hiring Headaches

Every warehouse manager knows the pain of turnover. You spend weeks hiring, training, and onboarding — only to lose people just as they become productive. The hidden expense of AI in warehousing turnover costs is enormous: lost productivity, safety risks, and a constant drain on supervisors. That’s why AI is becoming a game-changer. Instead of relying on endless cycles of “hire, train, replace,” AI helps reduce dependency on raw headcount and stabilize operations.

Why Warehouses Bleed from Turnover

Training Costs → Thousands of dollars and weeks of time before new hires are productive.

Productivity Gaps → Every lost associate leaves a hole that ripples through the team.

Safety Risks → New, untrained employees are more likely to make mistakes.

Culture Impact → Constant churn erodes morale and consistency.

The traditional solution? Hire more people and hope they stick. But it’s expensive and unsustainable.

How AI Reduces Turnover Costs

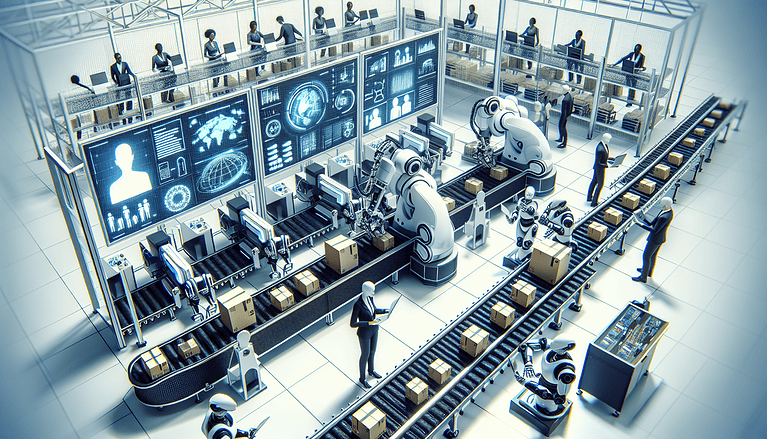

AI doesn’t eliminate people. It shifts how you use them:

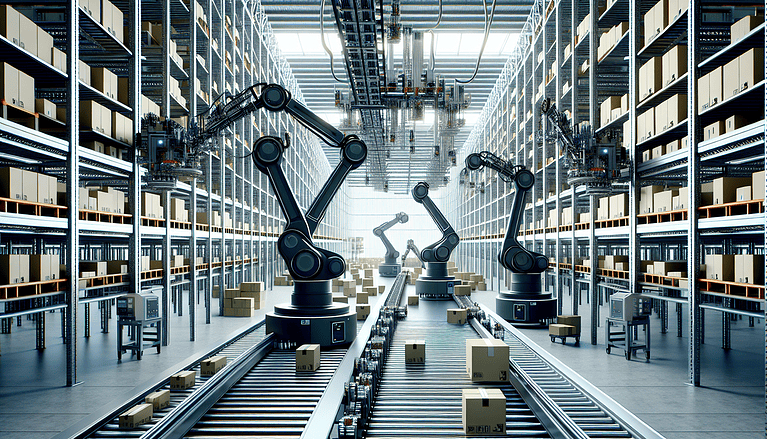

Automated Repetition → AI-driven robotics and automation handle routine moves (e.g., pallet transport, scanning, replenishment). Fewer people doing repetitive tasks means less burnout.

Smarter Scheduling → AI forecasting predicts demand and matches labor needs in advance, reducing overtime fatigue and turnover.

Decision Support → AI takes the guesswork out of slotting, putaway, and replenishment, so workers focus on execution, not confusion.

Upskilling Opportunities → As routine tasks shift to automation, employees can be trained into higher-value roles, improving retention.

AI-Driven Demand-Based Scheduling: Game-Changing Flex for Warehouses

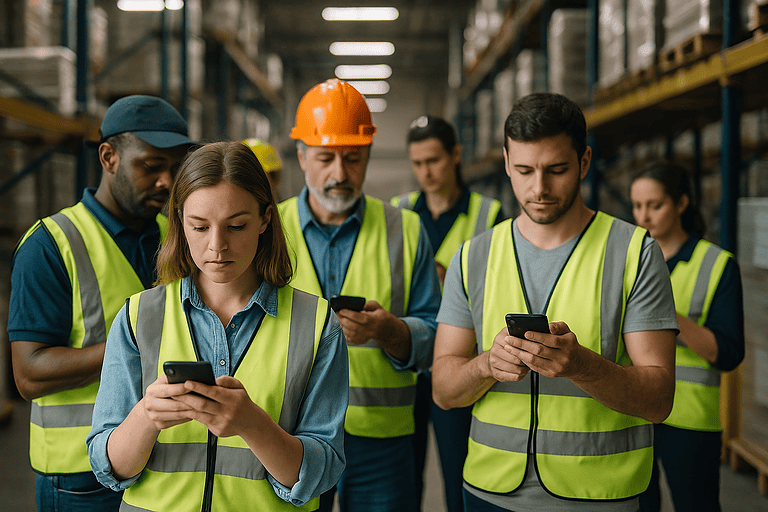

Picture this: an app that lets warehouse associates self-schedule with flexibility — nights, weekends, last-minute shifts — all with real-time updates and dynamic pay. It’s like a hybrid of Instacart-style surge pricing and Doordash flexibility, tailored for warehousing.

Here’s How It Could Work:

Flexible Scheduling App

Associates log into a centralized app to select shifts (days, nights, weekends). AI signals shifts that are hard to fill — maybe they pay $2 extra for a Friday night slot — motivating people to pick up critical gaps.AI-Driven Demand Forecasting

Behind the scenes, AI analyzes demand spikes (perhaps driven by a marketing blitz or randomized promo) and predicts staffing needs. If demand surges unexpectedly, the system pushes real-time alerts to workers most likely to take those shifts — whether they’ve volunteered before or recently worked off-hours.Smart Notifications for the Right Workers

Instead of mass alerts, the app nudges only relevant employees (e.g., night shift veterans or weekend regulars), reducing alert fatigue and improving fill rates.Game-Like Incentives

This becomes a high-engagement system. A last-minute Friday night shift might pay more. A $ bonus or highlight in the app newsfeed (‘Shift Hero of the Week’). It gamifies scheduling and rewards flexibility, improving both fill rates and morale.

Check out our blog post on AI in Warehousing: Flexible App-Based Scheduling with Dynamic Pay → where we’ll dive deep into how AI-driven scheduling apps can boost retention, reduce turnover, and reward flexibility.

A Practical Example

At one site I reviewed, turnover in case-pick aisles was over 40% annually. Why? The work was repetitive, backbreaking, and thankless.

By deploying AI-directed putaway and automated pallet movers, the operation reduced the need for constant manual replenishment. The associates who stayed were retrained in quality control and flow management — resulting in less physical strain and more engagement. Within a year, turnover dropped below 20%.

According to Deloitte’s 2023 supply chain workforce study, labor shortages and high turnover are the top challenges facing warehouses. Companies using AI-driven tools, however, report faster onboarding and improved retention.

For more on labor efficiency, see my post on Warehouse Staff Training — AI works best when paired with a strong foundation of people development.

Final Thought on AI in Warehousing Turnover Costs

Turnover will never disappear completely, but AI in warehousing can shift the equation regarding turnover costs. Instead of burning cash on constant hiring cycles, AI helps stabilize operations by reducing repetitive strain, predicting labor needs, and empowering employees to focus on higher-value work.

That’s the adaptive warehouse in action — less churn, more consistency, and stronger results.