Warehouse Data Analytics: Turning Information Into Action

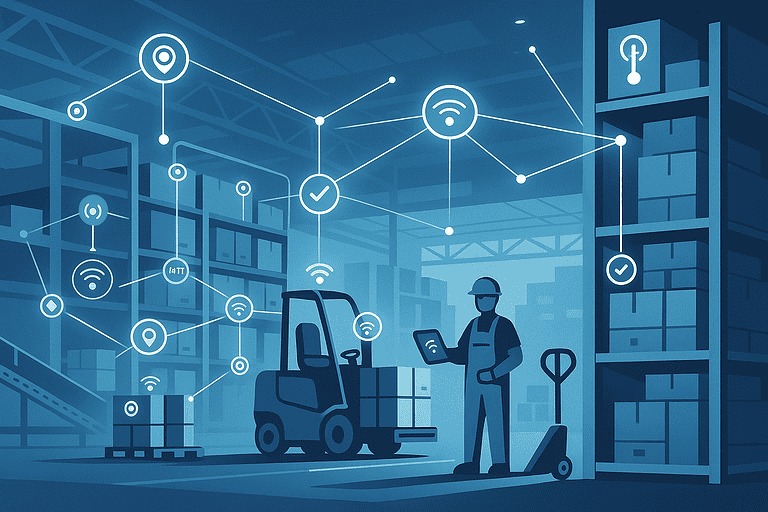

Warehouse data analytics is no longer a luxury—it’s a necessity for modern supply chains. By analyzing data from WMS, IoT sensors, and daily operations, warehouses can uncover inefficiencies, predict demand more accurately, and make smarter decisions that improve both speed and cost efficiency.

What Is Warehouse Data Analytics?

Warehouse data analytics is the practice of collecting, analyzing, and interpreting operational data to improve performance. It leverages systems such as WMS, IoT devices, RFID scanners, and ERP platforms, transforming raw data into actionable insights for inventory management, labor planning, and process optimization.

7 Ways Warehouse Data Analytics Boosts Efficiency

1. Improving Inventory Accuracy

By analyzing cycle counts, stock movements, and shrinkage patterns, managers can reduce discrepancies and maintain accurate records.

2. Reducing Operational Costs

Analytics highlight high-cost areas—such as excess overtime, bottlenecks, or underutilized equipment—so leaders can take prompt action.

3. Optimizing Space Utilization

Data reveals which storage zones are underutilized and which are overloaded, enabling smarter slotting and more effective space allocation.

4. Enhancing Labor Productivity

Performance metrics help balance workloads, identify training needs, and recognize top-performing employees.

5. Predicting Demand and Replenishment

Warehouse data analytics integrates with AI forecasting to predict demand shifts, ensuring timely and accurate replenishment.

6. Streamlining Receiving and Shipping

Analytics on dock-to-stock times, shipment accuracy, and carrier performance reveal areas for improvement in throughput.

7. Improving Customer Satisfaction

Better data leads to fewer stockouts, faster shipping, and more accurate orders—directly improving customer experience.

Challenges in Implementing Data Analytics

Data silos: Information scattered across multiple systems.

Integration issues: Legacy WMS may not connect easily with modern tools.

Data quality: Inaccurate or incomplete data leads to poor insights.

Skill gap: Teams may lack experience in interpreting and analyzing data.

Real-World Examples

Amazon leverages real-time analytics to forecast product demand and optimize warehouse robotics.

Walmart integrates supplier and warehouse data to maintain high on-shelf availability.

3PL providers utilize analytics to distribute workloads evenly across client accounts.

The Future of Warehouse Data Analytics

AI + machine learning: Automated demand forecasting.

Digital twins: Simulated warehouses for scenario testing.

IoT expansion: More granular, real-time data capture.

Blockchain: Secure, transparent data sharing across supply chains.

Conclusion

Warehouse data analytics is the key to moving from reactive decisions to a proactive strategy. By transforming data into actionable insights, warehouses can reduce costs, improve operational speed, and enhance customer satisfaction. Companies that embrace analytics today will have a competitive advantage in tomorrow’s data-driven supply chain.