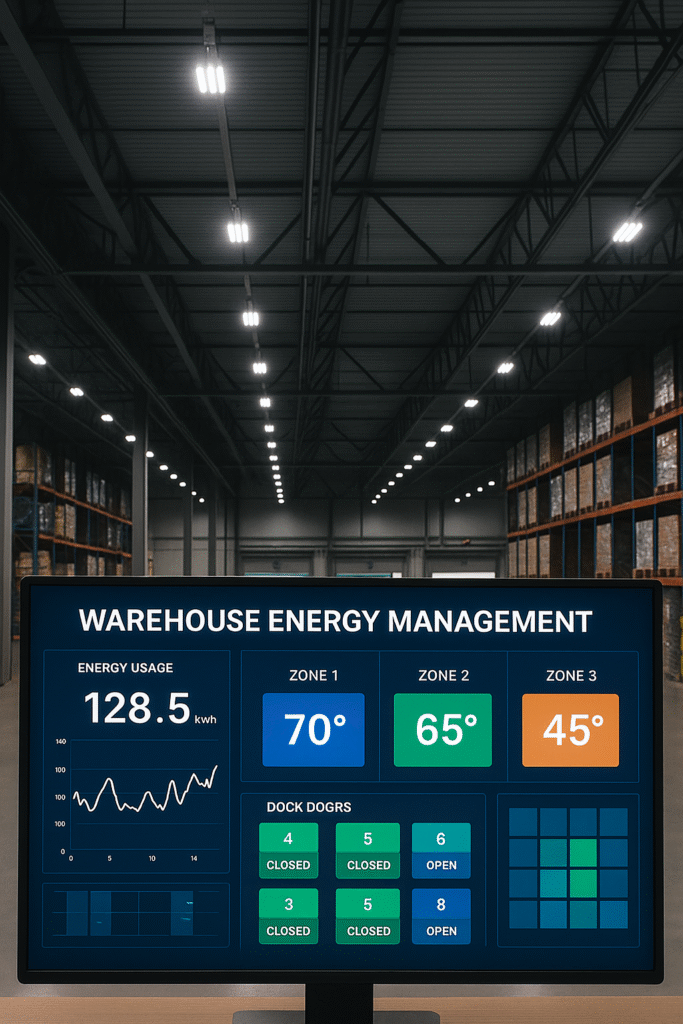

Warehouse Energy Management: Strategies to Reduce Costs and Emissions

Warehouse energy management is one of the fastest, cleanest levers to lower operating costs. With the right mix of quick wins and smart capital upgrades, you can shrink kWh, tame peak demand, and hit ESG goals—without hurting throughput.

Key Takeaways

Start with measure → target → tune: submeter, set KPIs, then optimize.

Quick wins: LED high-bays, controls, dock door sealing, and setpoint discipline.

Bigger moves: variable-speed drives, high-efficiency HVAC/refrigeration, solar + batteries, demand response.

Track results with kWh/ft², kWh per order, and peak kW to prove ROI.

1) Benchmark and Submeter First

Capture a 30–60 day baseline: total kWh, peak kW, power factor.

Submeter by zone (lighting, HVAC/refrigeration, conveyors, compressors, chargers).

KPIs to track: kWh/ft²/month, kWh per order, kW per dock, refrigeration kWh/ton.

Tooling: smart meters, wireless CT clamps, cloud dashboards.

2) Convert to LED High-Bays + Controls

Replace metal halide/T5 fixtures with LED high-bays (achieving 70–80% savings).

Add occupancy sensors, daylight harvesting, and aisle-based group control.

Target 30–50 foot-candles in pick/pack, 10–20 in bulk storage; reduce after hours.

3) Dial In HVAC and Refrigeration

Setpoints: 66–72°F office, 60–68°F production, tighter deadbands.

VFDs on fans and pumps, EC motors on evaporators, and floating head pressure.

Destratification fans in high-bay spaces to cut winter gas use.

Quarterly PM: coil cleaning, filter management, door curtain integrity.

4) Seal the Building Envelope and Docks

High-speed or insulated dock doors, quality seals/shelters, and air curtains.

Repair gaps around levelers and install strip curtains at cooler/freezer entries.

Score each door monthly: open time, seal condition, air loss.

5) Right-Size Material Handling Energy

VFDs on conveyor motors and zone-activated accumulation.

Idle logic: pause lines during breaks; power down unused zones.

For compressed air: fix leaks, lower header pressure, and use electric actuators where possible.

6) Smart Charging for Forklifts and AMRs

Stagger chargers to avoid demand spikes; enable off-peak charging windows.

Use opportunity charging rules tied to WMS tasking and shift breaks.

Monitor charger efficiency and battery health to prevent wasted kilowatt-hours (kWh).

7) Manage Peak Demand and Join Demand Response

Identify the top 20 peak kW events.

Create a peak-day playbook: pre-cool zones, delay deferrable tasks, throttle conveyors, stagger charging.

Enroll in utility demand response programs for cash incentives.

8) On-Site Renewables and Storage

Rooftop solar PV to offset daytime loads; evaluate PPA vs. ownership.

Battery energy storage to shave peaks and back up critical zones (IT, cold storage).

Model solar + storage against your interval data for true ROI.

9) Institutionalize with ISO 50001-Lite

Assign an Energy Champion and cross-functional team.

Monthly review: KPI scorecard, exceptions, corrective actions.

Standardize SOPs: lighting schedules, setpoint changes, charger windows, door discipline.

KPIs and Targets

kWh/ft²/month: trending down 10–25% after LEDs + controls.

kWh per order: impact of process changes and slotting.

Peak kW: 10–20% reduction with charging controls + peak playbooks.

Lighting runtime hours and door open time per dock.

Implementation Roadmap (90 Days)

Weeks 1–3: metering setup, baseline, quick fixes (schedules, setpoints).

Weeks 4–6: LED + controls plan, dock sealing scope, VFD audit.

Weeks 7–9: charger policy + BMS tweaks, peak playbook.

Weeks 10–12: DR enrollment, solar/storage feasibility, KPI dashboard rollout.

FAQs

What is warehouse energy management?

A structured approach to measure, control, and reduce energy across lighting, HVAC, material handling, docks, and charging systems.

What are the fastest payback items?

LED + controls, setpoint optimization, dock sealing, charger scheduling, leak fixes—often <18 months.

How do I avoid hurting throughput?

Tie controls to WMS/WES status, use occupancy sensing by aisle, and schedule energy actions outside peak processing windows.

Do I need a building management system?

Not required, but a BMS or cloud EMS simplifies controls, trending, and alarms—especially in multi-site portfolios.

Additional Resources

U.S. DOE Better Buildings: Energy management resources – energy treasure hunts, lighting, HVAC.

ENERGY STAR for Industry: Portfolio Manager + benchmarking guidance.