Augmented Reality Warehousing: Transforming Operations and Efficiency

Augmented Reality warehousing is no longer futuristic—it’s becoming a practical tool for warehouses aiming to cut costs, improve accuracy, and empower workers. AR overlays digital information onto the real environment, helping warehouse teams complete tasks faster, safer, and with fewer errors.

How AR Works in the Warehouse

Smart Glasses or Tablets: Workers see visual prompts, pick paths, or order details overlaid in real-time.

AR Headsets: Provide hands-free guidance, reducing the need for handheld scanners or paper lists.

System Integration: AR connects to Warehouse Management Systems (WMS) to display live inventory and order information.

5 Benefits of Augmented Reality Warehousing

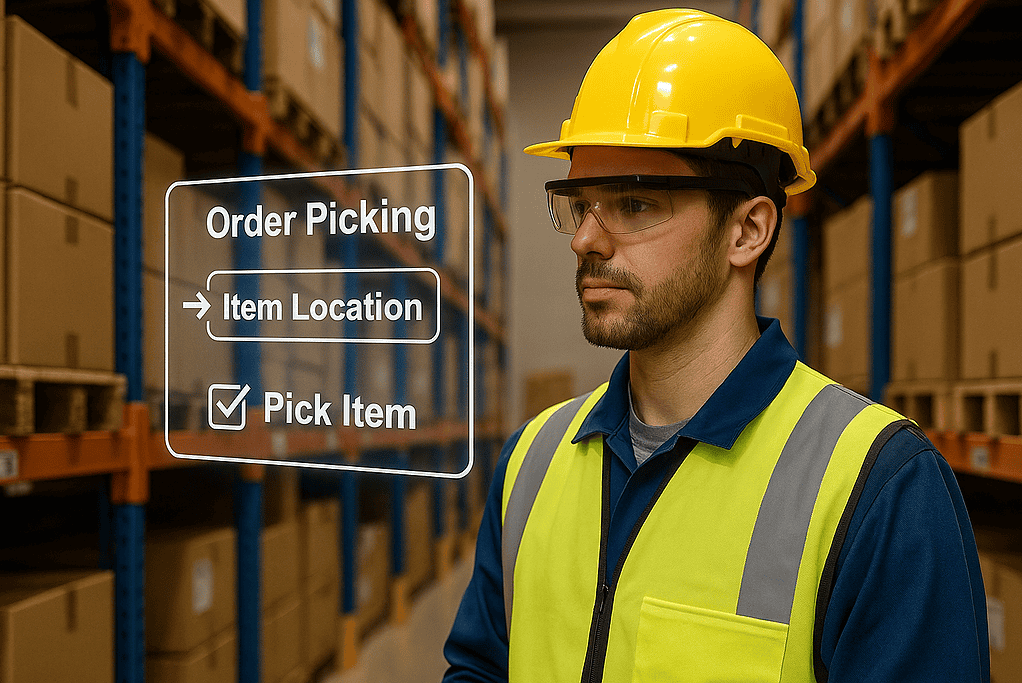

Improved Picking Accuracy – AR highlights the exact location of items, reducing errors.

Faster Training – New employees can learn through guided overlays, eliminating the need to memorize complex layouts.

Enhanced Safety – AR warns workers about hazards like blocked aisles or moving forklifts.

Higher Productivity – Workers save time by following optimized AR routes rather than paper pick sheets.

Better Inventory Visibility – AR tools can instantly display stock levels, locations, and product data.

Real-World Use Cases

AR Picking Systems – DHL, UPS, and Amazon have piloted AR picking for faster fulfillment.

Maintenance & Repair – Technicians use AR overlays for step-by-step equipment fixes.

Training Programs – Interactive AR tutorials shorten ramp-up time for new hires.

Challenges and Considerations

Cost – AR devices and integration can be expensive.

Adoption – Worker comfort with new technology may vary.

Data Security – Real-time data feeds must be secure.

Conclusion

Augmented Reality warehousing is helping companies boost accuracy, reduce training time, and improve efficiency. While adoption challenges exist, AR is becoming a strategic tool that bridges human labor and digital intelligence inside the warehouse.