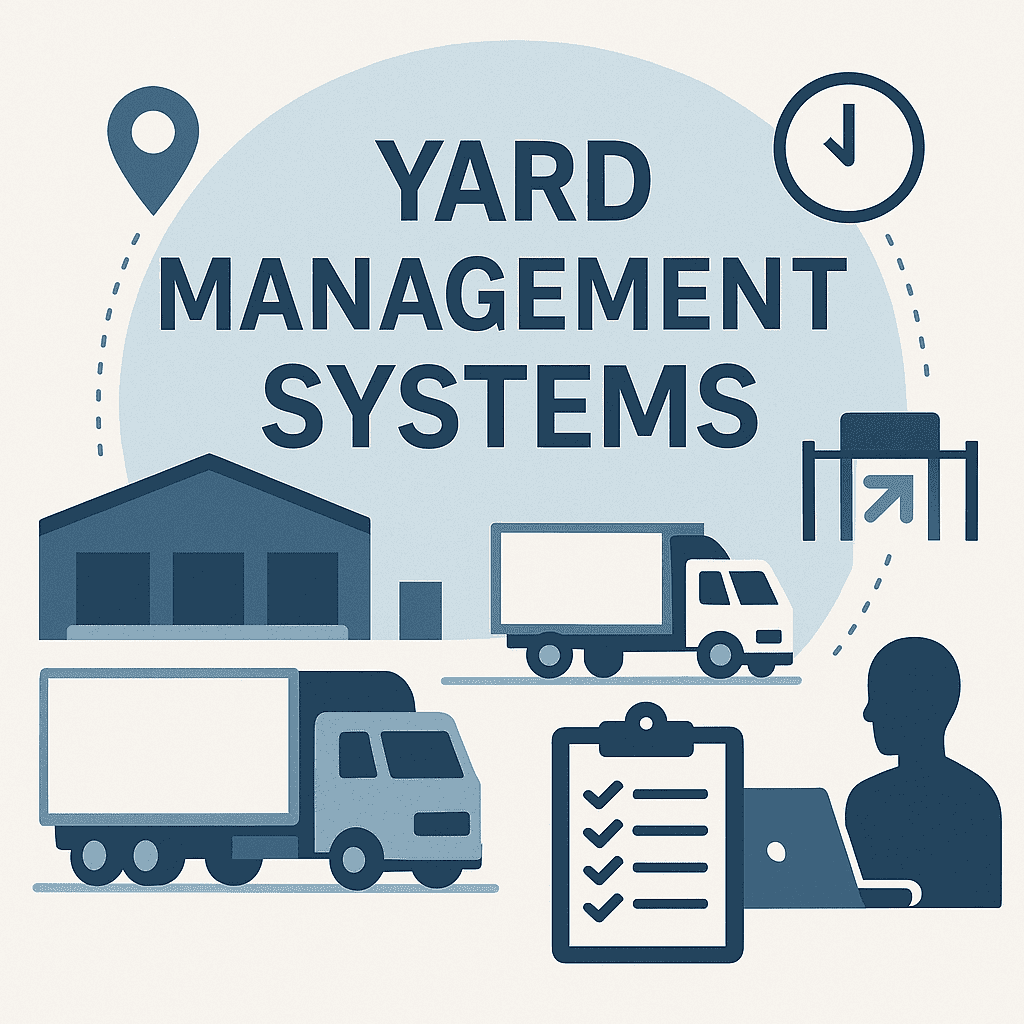

Yard Management Systems: The Key to Smarter Warehouse Operations

Yard Management Systems (YMS) are becoming essential tools for warehouses, distribution centers, and manufacturing facilities that manage high volumes of inbound and outbound trailers. Without a proper system, yards can quickly become bottlenecks—leading to delays, increased labor costs, and unhappy customers. Implementing a YMS gives operations leaders real-time visibility into trailer locations, dock assignments, and gate movements, creating a more efficient and reliable supply chain.

What is a Yard Management System?

A Yard Management System (YMS) is software designed to monitor and control the movement of trailers, trucks, and containers within the yard of a warehouse or distribution center. Unlike Warehouse Management Systems (WMS), which manage goods inside the building, YMS focuses on activities outside the four walls.

YMS Key functions include:

Tracking trailer arrivals and departures

Assigning dock doors for unloading/loading

Managing yard jockeys and trailer moves

Real-time visibility into yard inventory

Benefits of Yard Management Systems

1. Improved Visibility

Operators can see exactly where each trailer is located, reducing time wasted searching for equipment.

2. Faster Turnaround

Dock scheduling and gate management streamline check-in, cutting detention fees and improving carrier relations.

3. Reduced Costs

Automation minimizes manual check-ins, reduces yard congestion, and optimizes yard jockey assignments.

4. Stronger Compliance & Safety

YMS ensures trailers are placed in safe zones, prevents unauthorized access, and provides audit trails for compliance.

5. Better Carrier Relationships

Carriers benefit from quicker turn times, reduced detention, and clearer communication.

Core Features of a YMS

When evaluating Yard Management Systems, look for:

Gate Management: Automated check-in/check-out

Dock Scheduling: Integration with WMS/TMS for seamless flow

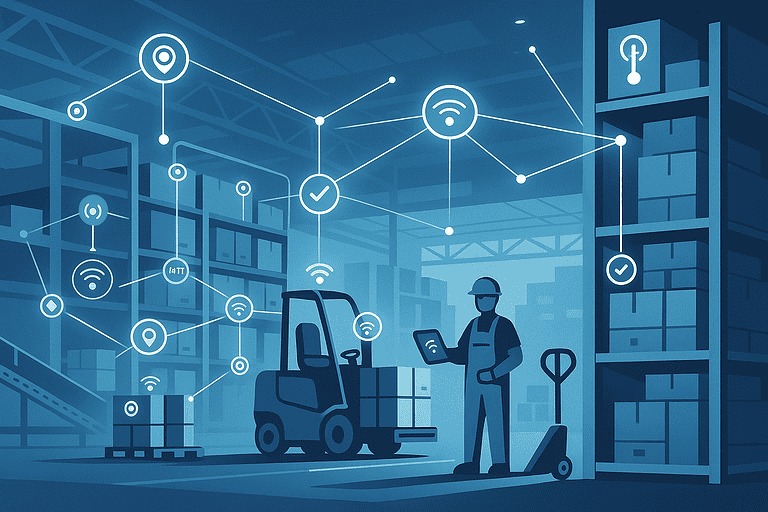

Real-Time Trailer Tracking: RFID, GPS, or barcode scanning

Task Management: Assigns moves to jockeys and monitors completion

Analytics & Reporting: Visibility into yard utilization, dwell times, and bottlenecks

Best Practices for Implementing a YMS

Integrate with Existing Systems – Connect your YMS with WMS and TMS for end-to-end visibility.

Start with Pilot Sites – Test at one location before scaling enterprise-wide.

Train Staff Thoroughly – Yard jockeys, guards, and managers all need role-based training.

Use Data for Continuous Improvement – Monitor dwell times and yard utilization to drive improvements.

Future of Yard Management Systems

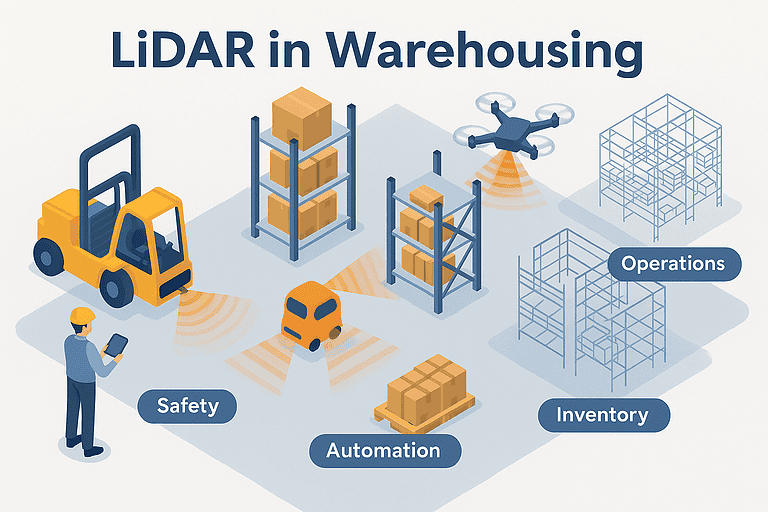

AI, IoT, and real-time tracking will shape the future of YMS. Smart sensors will provide predictive insights, such as identifying when a trailer is nearing capacity or when yard congestion is likely. Automation will further integrate with autonomous trucks and warehouse robotics, creating a fully connected ecosystem that spans from yard to warehouse.

Conclusion

Yard Management Systems are no longer optional for high-volume facilities. They provide visibility, efficiency, and control over one of the most critical yet overlooked parts of the supply chain. By adopting a YMS, companies can reduce costs, improve carrier relationships, and position themselves for long-term success.

FAQ Section

What is a Yard Management System?

A Yard Management System (YMS) is software that manages trailers, trucks, and containers in the yard of a warehouse or distribution center. It provides real-time visibility, automates check-in/check-out, and reduces bottlenecks.

👉 Learn more about Warehouse Management Systems and how they connect with YMS.

🔗 External: Gartner’s Guide to Yard Management Systems (great for credibility).

How is a YMS different from a WMS or TMS?

A Warehouse Management System (WMS) manages inventory inside the warehouse.

A Transportation Management System (TMS) handles shipping routes, freight, and carrier management.

A YMS bridges the gap, managing outside-the-four-walls trailer and yard activity.

👉 Related read: Inbound Software for smoother dock-to-yard integration.

🔗 External: Oracle TMS Overview.

What are the benefits of Yard Management Systems?

Benefits include improved trailer visibility, reduced detention costs, better yard safety, faster turnaround, and stronger carrier relationships.

👉 Explore more: Reduce Warehouse Costs and Warehouse Safety.

🔗 External: Inbound Logistics: YMS Benefits.

Who needs a Yard Management System?

YMS is most valuable for high-volume distribution centers, e-commerce facilities, manufacturing plants, and 3PLs where trailer congestion is common.

👉 Check out: 3PL Warehouse Guide to see how third-party logistics providers benefit.

🔗 External: Supply Chain Digital: Why YMS is critical for 3PLs.

What features should I look for in a YMS?

Look for dock scheduling, automated gate management, real-time trailer tracking, yard jockey task assignments, and reporting tools.

👉 Related post: Dock Scheduling and Cross-Docking Strategies.

🔗 External: Manhattan Associates Yard Management.

Can a YMS integrate with other systems?

Yes. Leading YMS solutions integrate with WMS, TMS, ERP, and IoT devices for full supply chain visibility.

👉 Dive deeper: IoT in Warehouse Management.

🔗 External: SAP Yard Logistics Integration.

What is the future of Yard Management Systems?

Emerging technologies like AI, IoT, and autonomous vehicles will make YMS predictive—identifying congestion before it happens and integrating with robotics for a fully automated yard.

👉 Future tech: AI in Warehousing and Autonomous Mobile Robots.

🔗 External: DHL Logistics Trend Radar (covers AI, IoT, and robotics in supply chains).